Articulating surgical tool

a surgical tool and articulating technology, applied in the field of surgical instruments, can solve the problems of insufficient inconvenient use inability to properly adjust the offset of offset broach handles, etc., and achieve the effect of improving the accuracy of the offs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

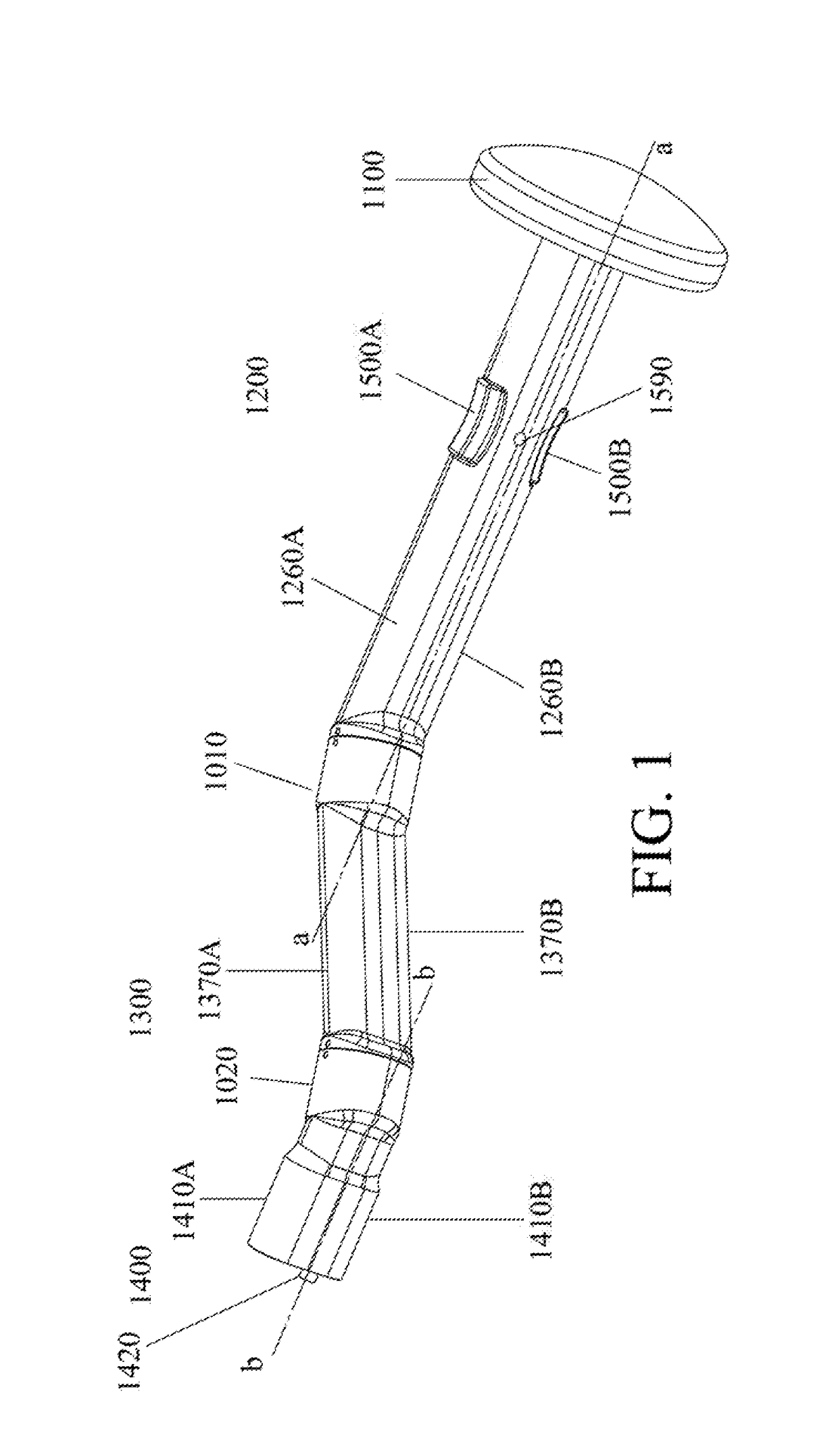

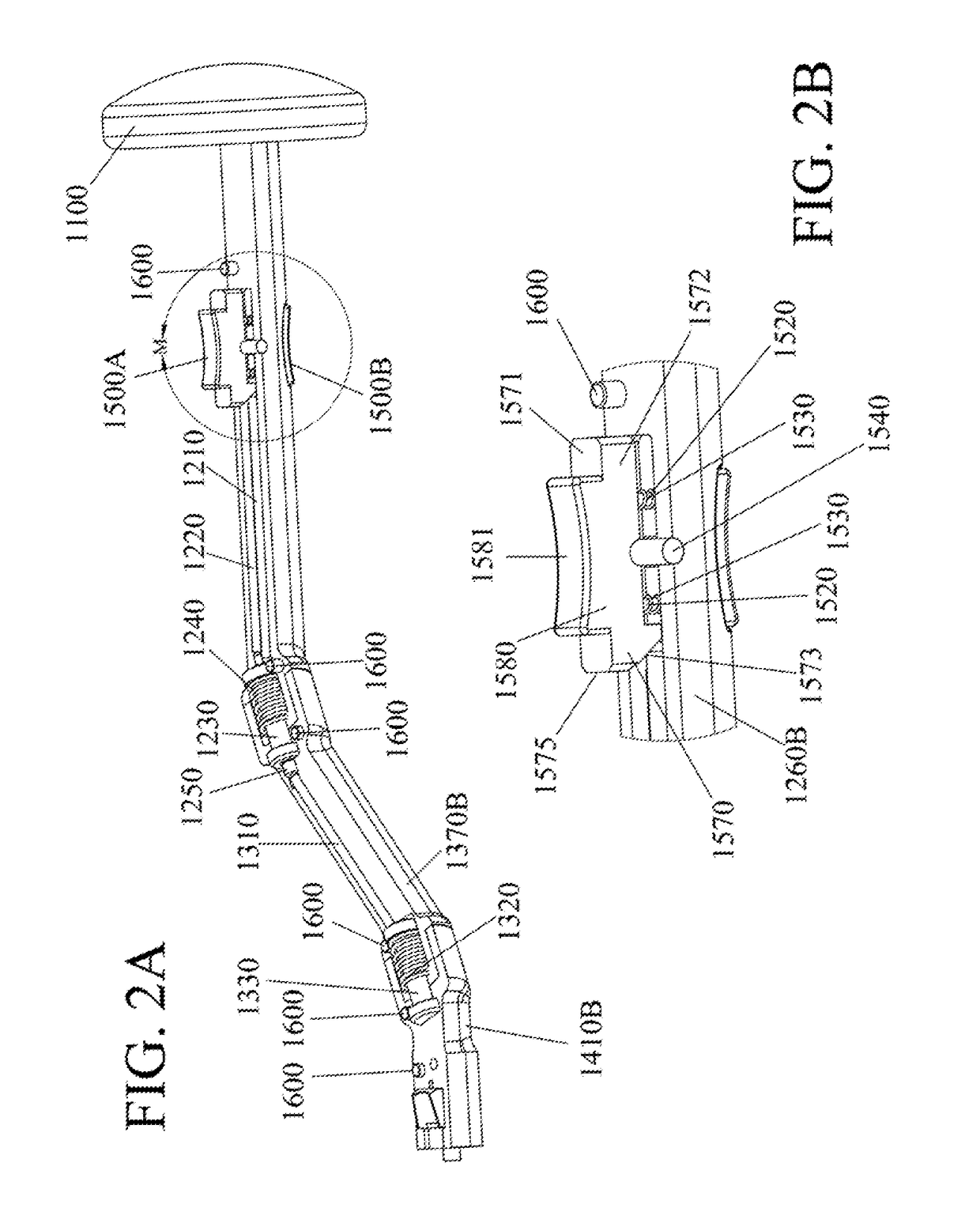

[0126]FIG. 1 depicts a first embodiment of the present invention as described in the context of a broach handle 1000. The broach handle from the proximal end to the distal end consists of a Force Disc 1100, a Main Section 1200, First and Second Triggers 1500A, 1500B, a Center Section 1300, and a Broach Section 1400. Each section (Main, Center and Broach) is constructed in two mirrored halves, top (a) and bottom (b) halves. The halves are semi-permanent or permanently affixed together. Semi-permanent attachment of the mirrored halves (sections) allow for disassembly. Each section is substantially solid with the exception of channels and cavities allowing the broach handle's internal components (described later) to be housed without excessive movement when assembled.

[0127]The proximal end of the Broach Handle 1000 comprises a circular shaped Force Disc 1100 (FIGS. 3A, 3B) and may have chamfered edges 1130. The diameter of the Force Disc is preferably 2.5 inches and a total thickness o...

embodiment 2

[0166]FIGS. 12, 13A, 13B and 14A depict a second embodiment of the articulating broach handle 2000 of this invention. Articulating broach handle 2000 includes 4 sections with 3 joints allowing articulation of the various sections. In the example described, 2 joints articulate in 45 degree increments and one joint articulates in 90 degree increments. It is understood that the amount of articulation per joint can vary. The broach handle from the proximal end to the distal end consists of a Force Disc 2100, a Main Section 2200, a First Connector Lock Sleeve 2600, a Center Section 2300, a Junction 2 2900, a Second Connector Lock Sleeve 2700, a 180 Joint 2400 (FIG. 28), a Third Connector Lock Sleeve 2800 and a Broach Section 2500. The Main and Center sections may be constructed in two mirrored halves, top (a) and bottom (b) halves or as a single structure. The halves may be semi-permanent or permanently affixed together. Semi-permanent attachment of the mirrored halves (sections) allow f...

embodiment 3

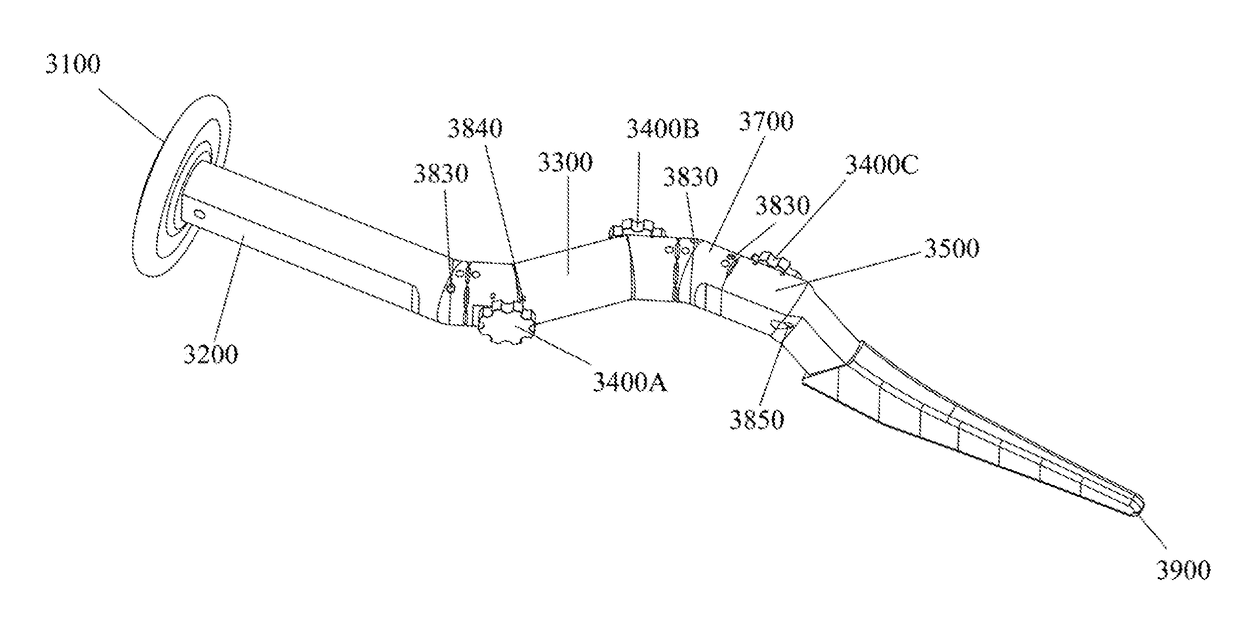

[0217]FIGS. 35 and 36A, B depict a third embodiment of the present invention as described in the context of an articulating broach handle 3000. The articulating broach handle from the proximal end to the distal end consists of a Force Disc 3100, a Main Section 3200 (FIG. 37), a Center Section 3300 (FIGS. 38A, B), a Connecting Body 3700 (FIGS. 39A, B) and a Broach Section 3500 (FIGS. 40A, B). The Main Section and the Center Section may articulate with respect to one another via a cam mechanism consisting of a Grip Cam 3400A (FIG. 41), a Push Rod 3810 (FIG. 42), a Rod Spinlock Pin 3830 (FIG. 45) and two Wheel Secure Pins 3840 (FIG. 47). A similar cam mechanism, Grip Cam 3400B, allows articulation of the Center Section 3300 with respect to the Connecting Body 3700. A third cam mechanism, Grip Cam 3400C, a Clasp Rod 3820 (FIG. 43) and two Wheel Secure Pins 3840 allows a Broach 3900 to be releasably engaged with Broach Handle 3000.

[0218]The Force Disc 3100 is similar to and provides the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com