Power supply for providing electrical energy to a self-destruct fuze for submunitions contained in a projectile

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

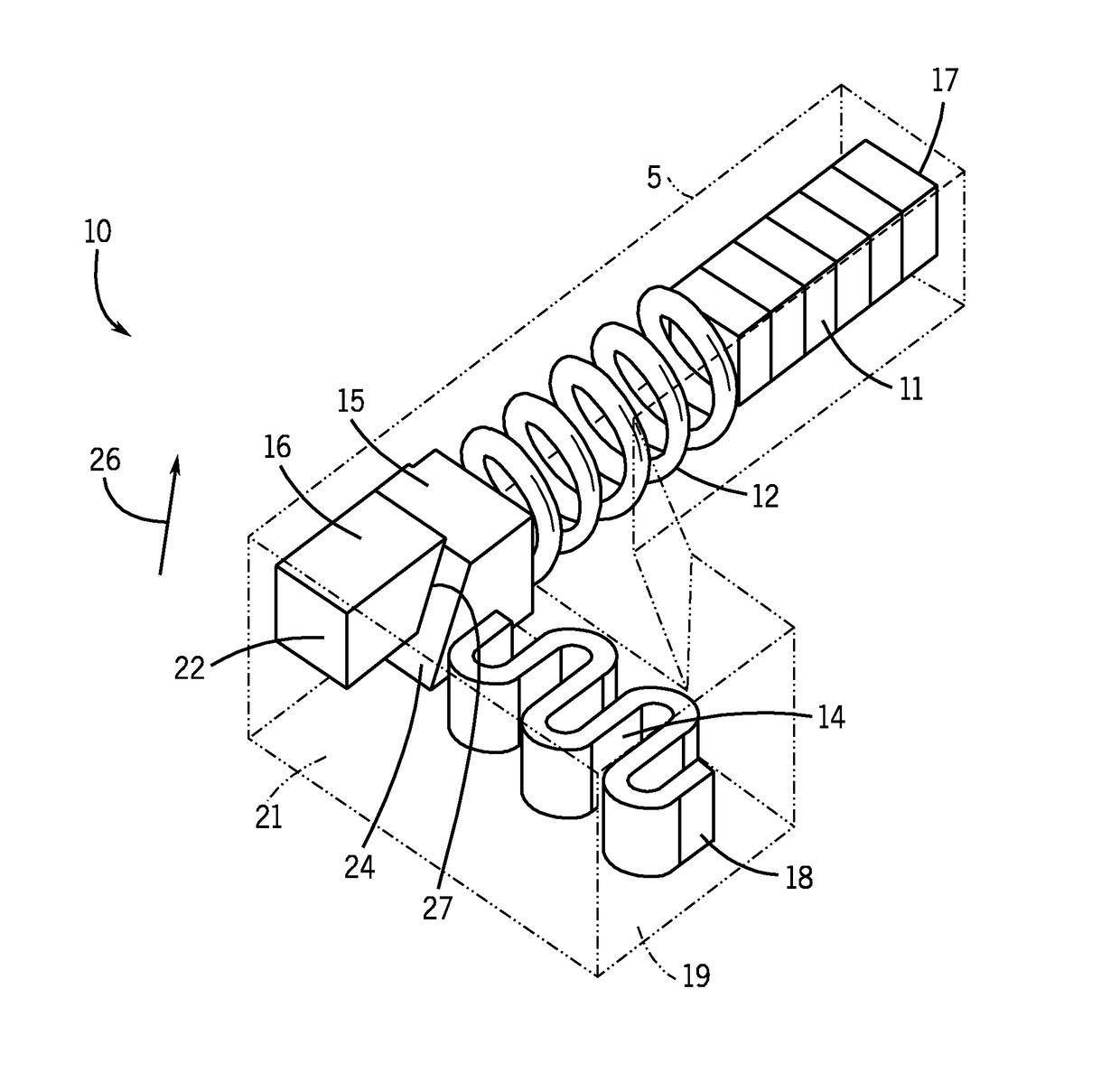

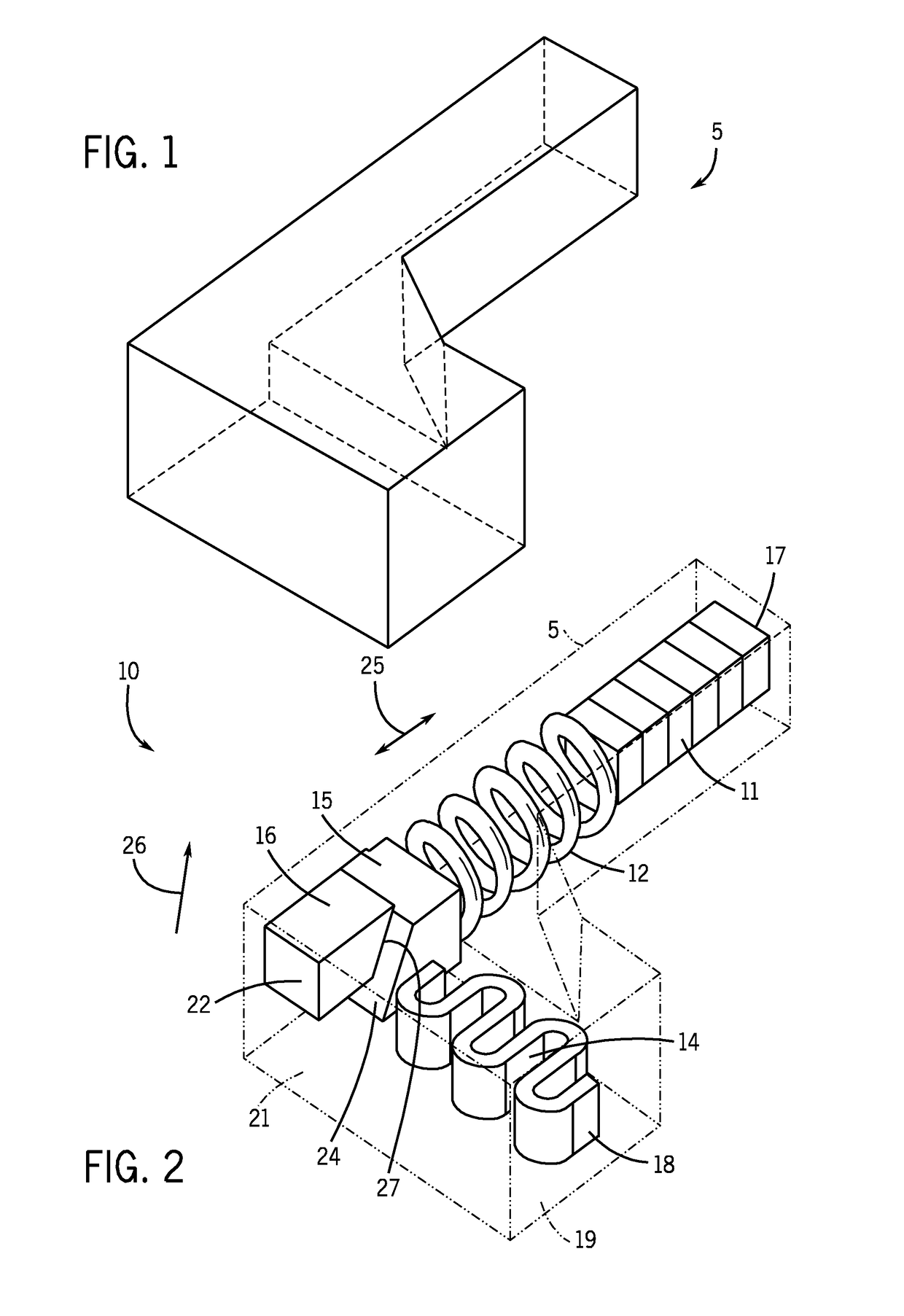

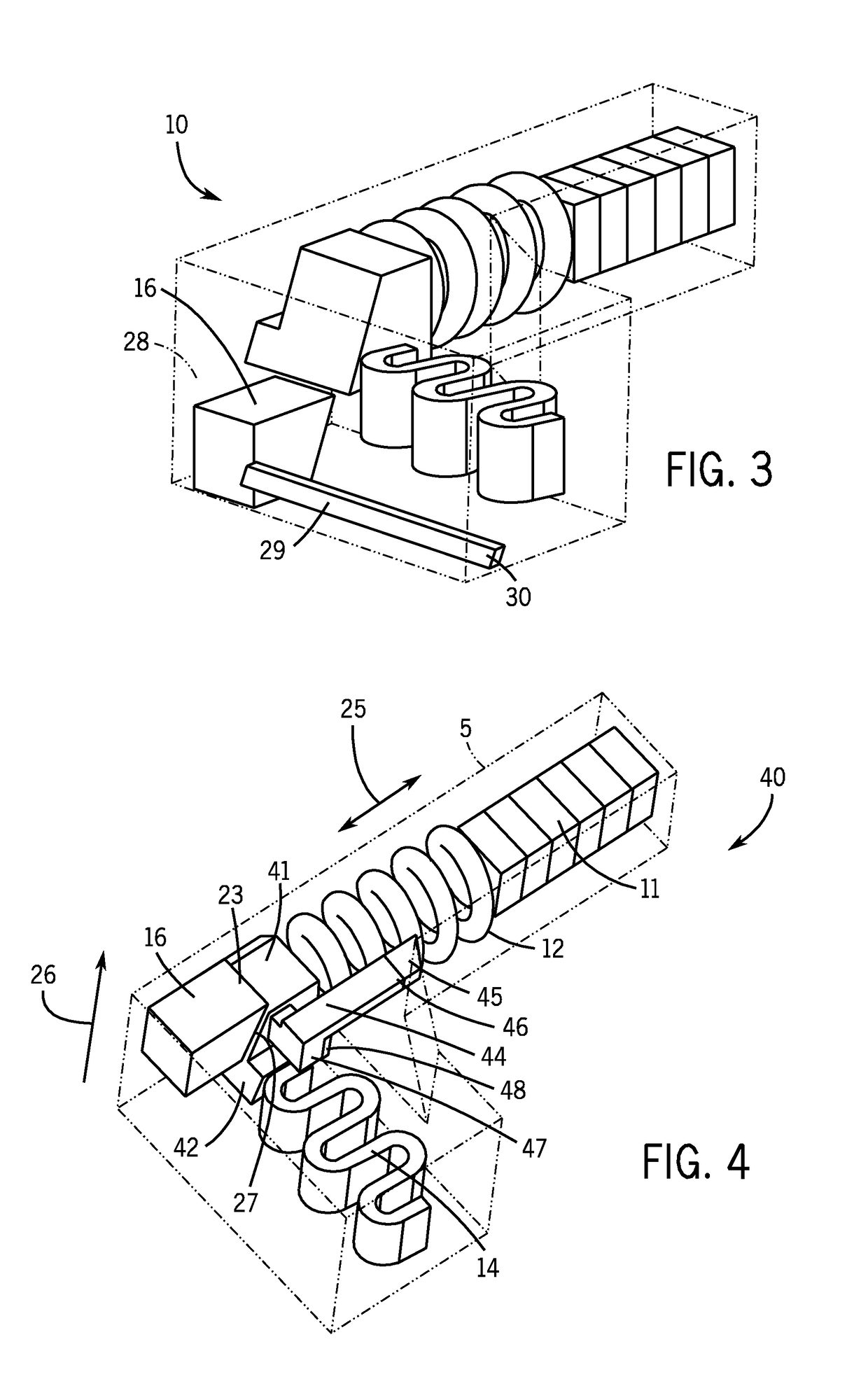

[0040]In general, the amount of space available for power sources and for the aforementioned safety mechanisms in submunitions self-destruct fuze is very small, making the use of chemical reserve batteries very difficult and costly, and nearly impractical. The use of active chemical batteries is not possible in submunitions due to the up to 20 years of shelf life requirement and also due to safety concerns that an active battery would generate. A typical volume available for a power source and its safety mechanisms is shown in FIG. 1 together with typical dimensions of this available space (see for example U.S. Pat. No. 5,387,257 by M. Tari, et al.). As can be observed, the available volume is very small and in many cases is a complex shape.

[0041]A method and apparatus are provided for power sources that could be designed to fit inside the available volume of the geometrical shape shown in FIG. 1 or other similarly complex shapes. In one embodiment, the power sources have substantia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com