Filling device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

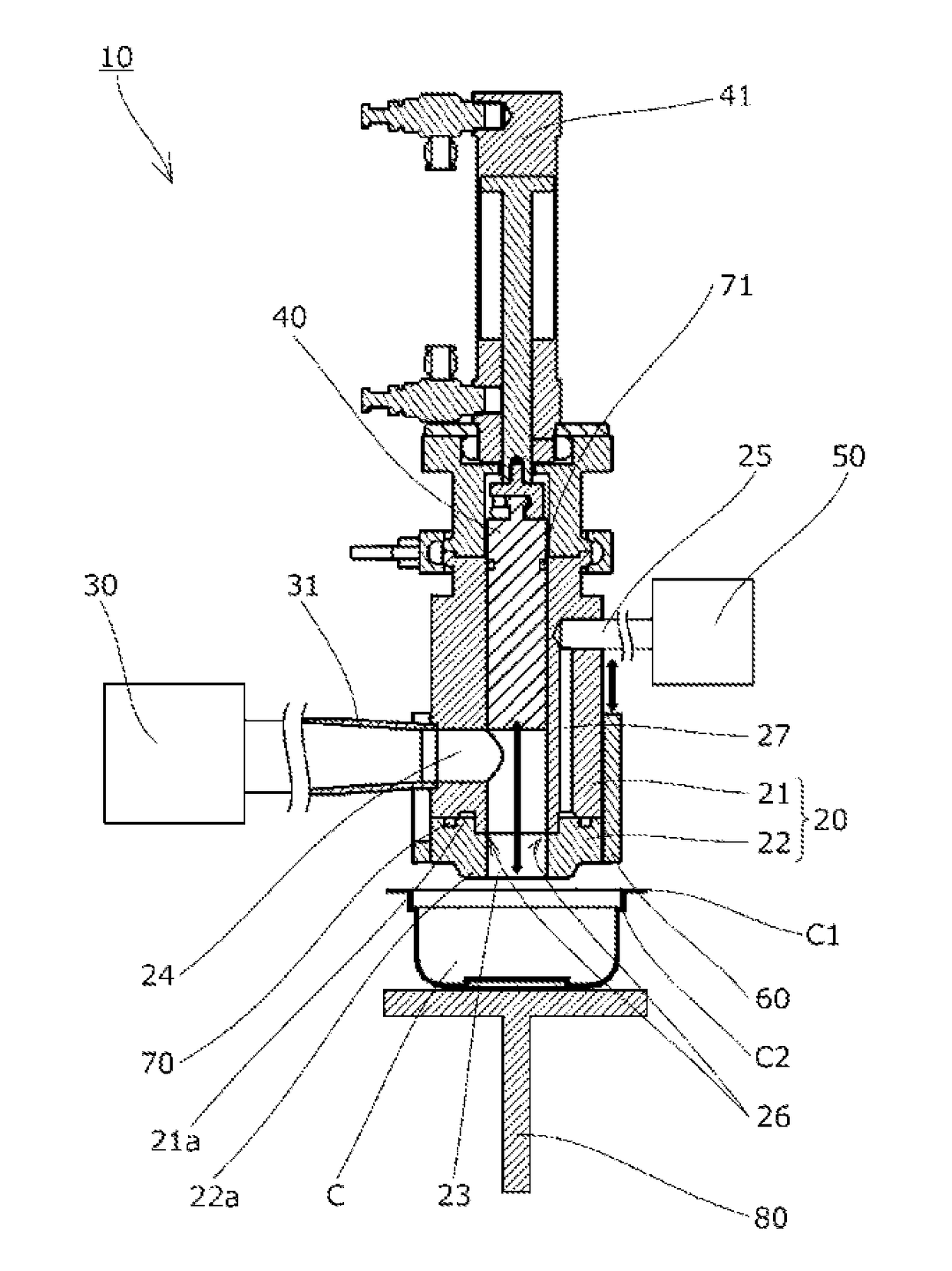

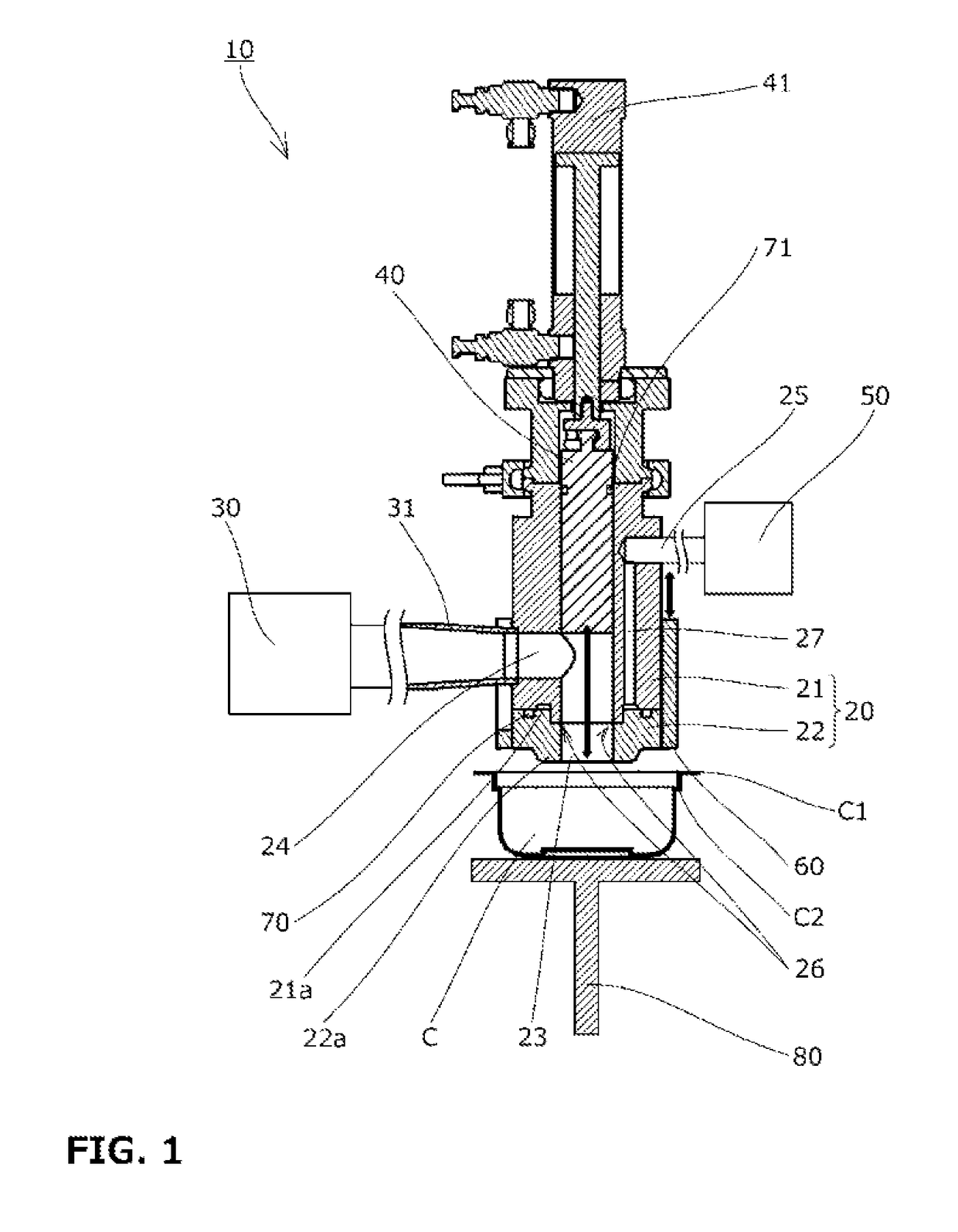

[0053]Below, the filling device 10 according to one embodiment of the present invention will be described with reference to the drawings.

[0054]The filling device 10 fills a container C with viscous contents B such as a meat product. As shown in FIG. 1, the device includes a filling nozzle 20 having a nozzle hole 23, a contents supplier 30 that supplies the contents B to the nozzle hole 23, a plunger 40 that is disposed inside the nozzle hole 23 such as to be movable up and down and pushes out the contents B supplied to the nozzle hole 23 downward, a gas supplier 50 that supplies a gas A, a nozzle cover 60 placed around the filling nozzle 20, first and second packings 70 and 71 in an annular form that seal respective parts, and a container lifter 80 that moves the container C up and down.

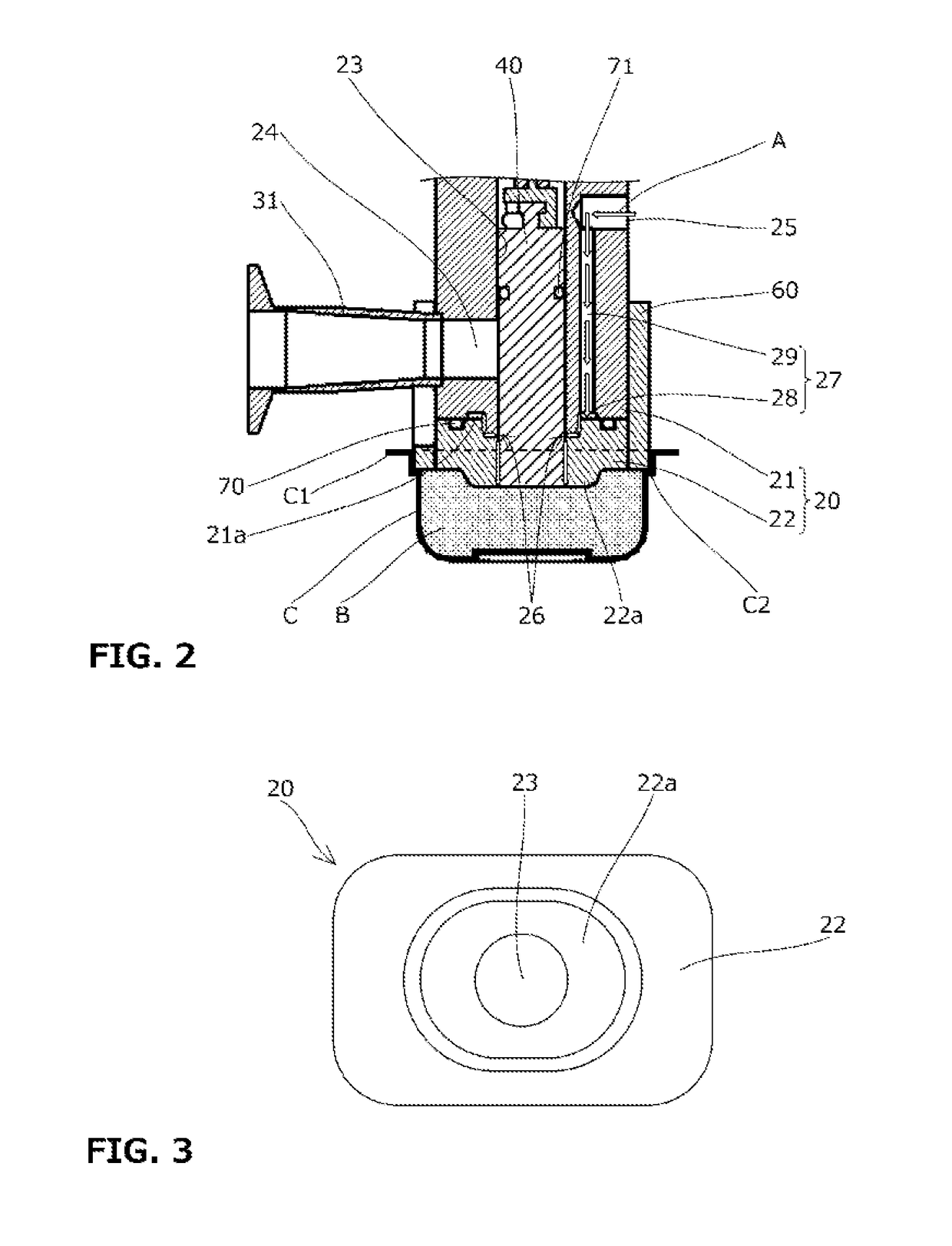

[0055]The constituent elements of the filling device 10 will each be described below with reference to FIG. 1 to FIG. 3.

[0056]First, the filling nozzle 20 includes a cylindrical nozzle hole 23 that e...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap