Weight plate

a weight plate and plate body technology, applied in the field of weight plates, can solve the problems of difficult lifting maneuver, flat sided weight plates do not have a convenient hand hold for users, and the difficulty of picking up weight plates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

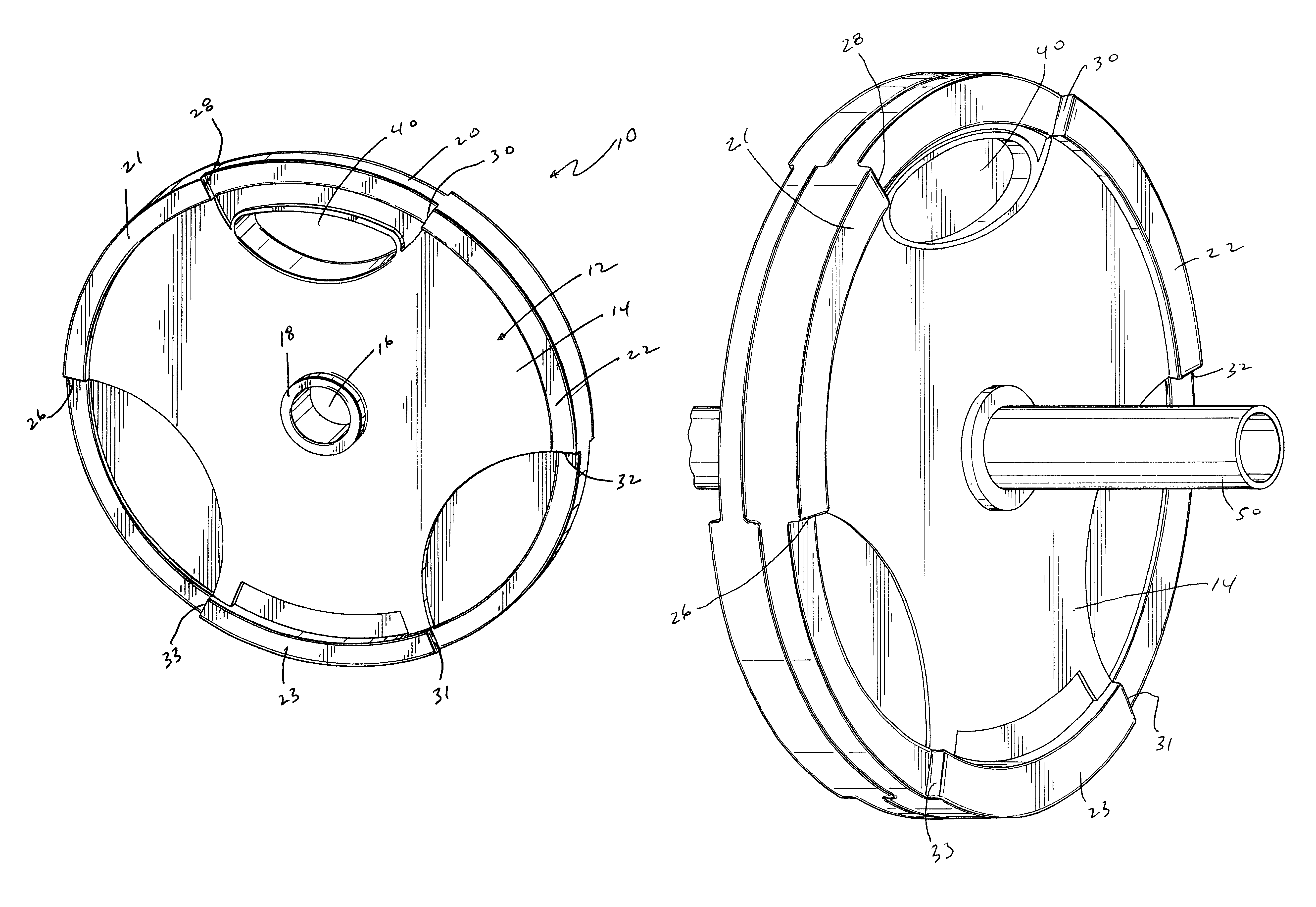

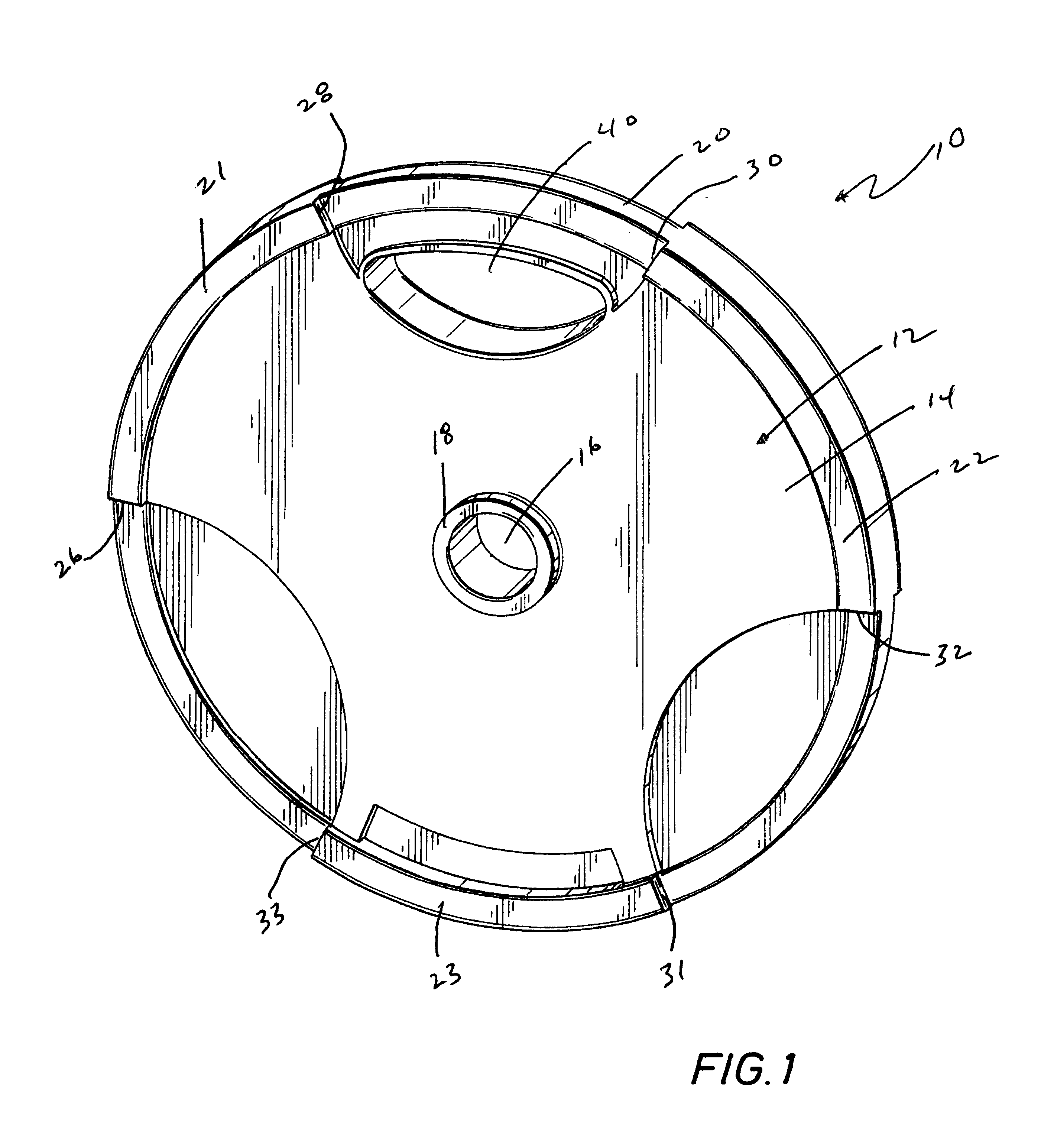

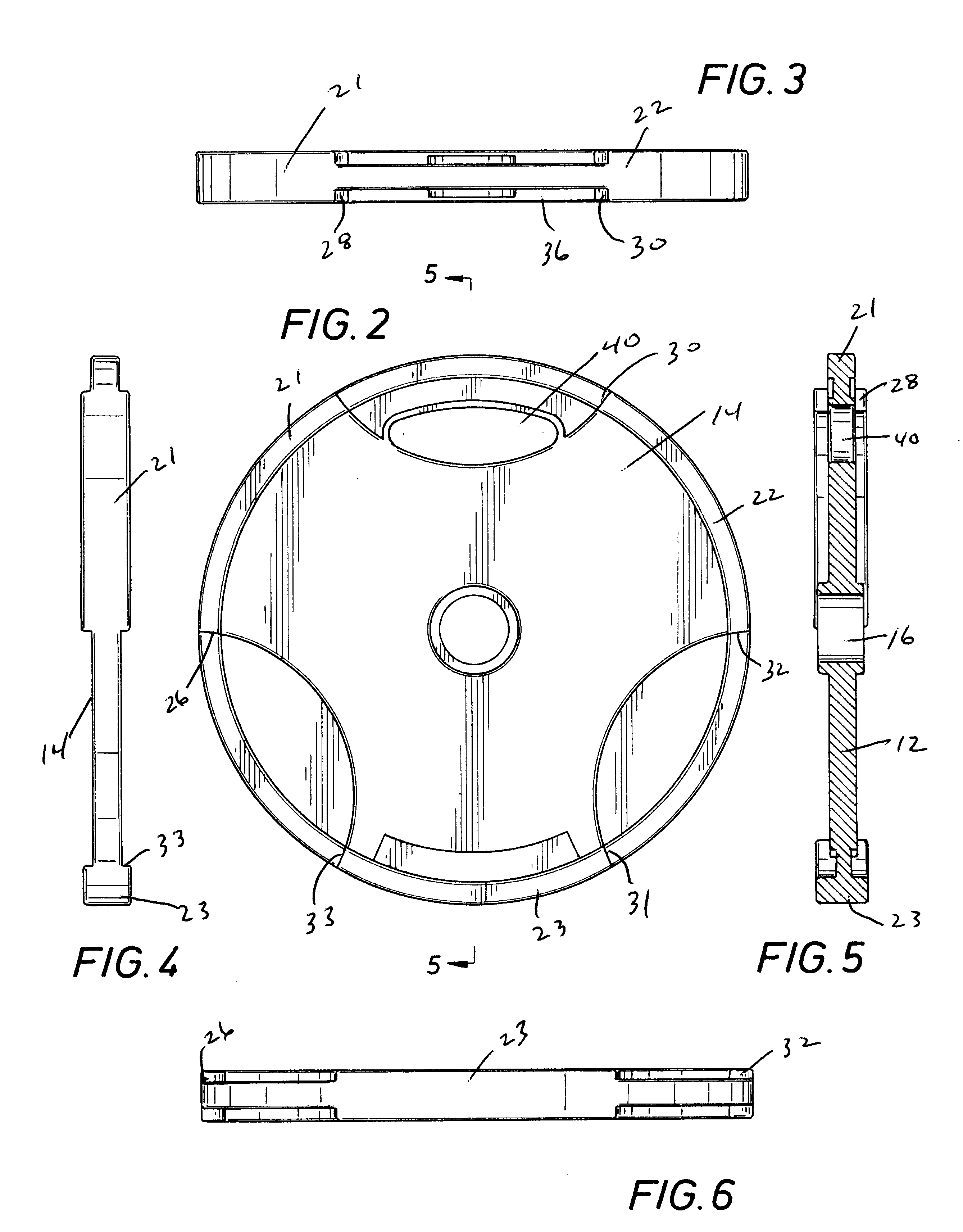

Referring first to FIG. 1, the weight plate of the invention is generally identified by the reference numeral 10. The weight plate 10 may be cast, rubber coated and / or polyurethane coated. The weight plate 10 includes a substantially flat body 12 defined by first and second planar surfaces 14. The planar surfaces 14 are generally opposed and define the thickness of the plate 10. A centrally located bore 16 defines the rotational axis of the plate 10 and is adapted to receive a mounting member, such as a barbell or weight bar. The bore 16 is further defined by integrally formed collars 18 which circumscribe the bore 16 and project outwardly from the surfaces 14 of the weight plate body 12. The collars 18 are oriented perpendicular to the body surfaces 14 and add axial length to the bore 16. It is understood that the diameter of the bore 16 may vary to accommodate the diameter of a barbell or dumbbell bar to be received through the bore 16. The diameter of the bore 16 will generally v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com