Image display medium

a technology of image display and film, applied in the direction of electrical equipment, semiconductor devices, instruments, etc., can solve the problems of increasing the adhesive force and causing the peeling to occur, so as to prevent the warpage of plastic film, reduce the hygroscopicity of the coat layer, and prevent the wire break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

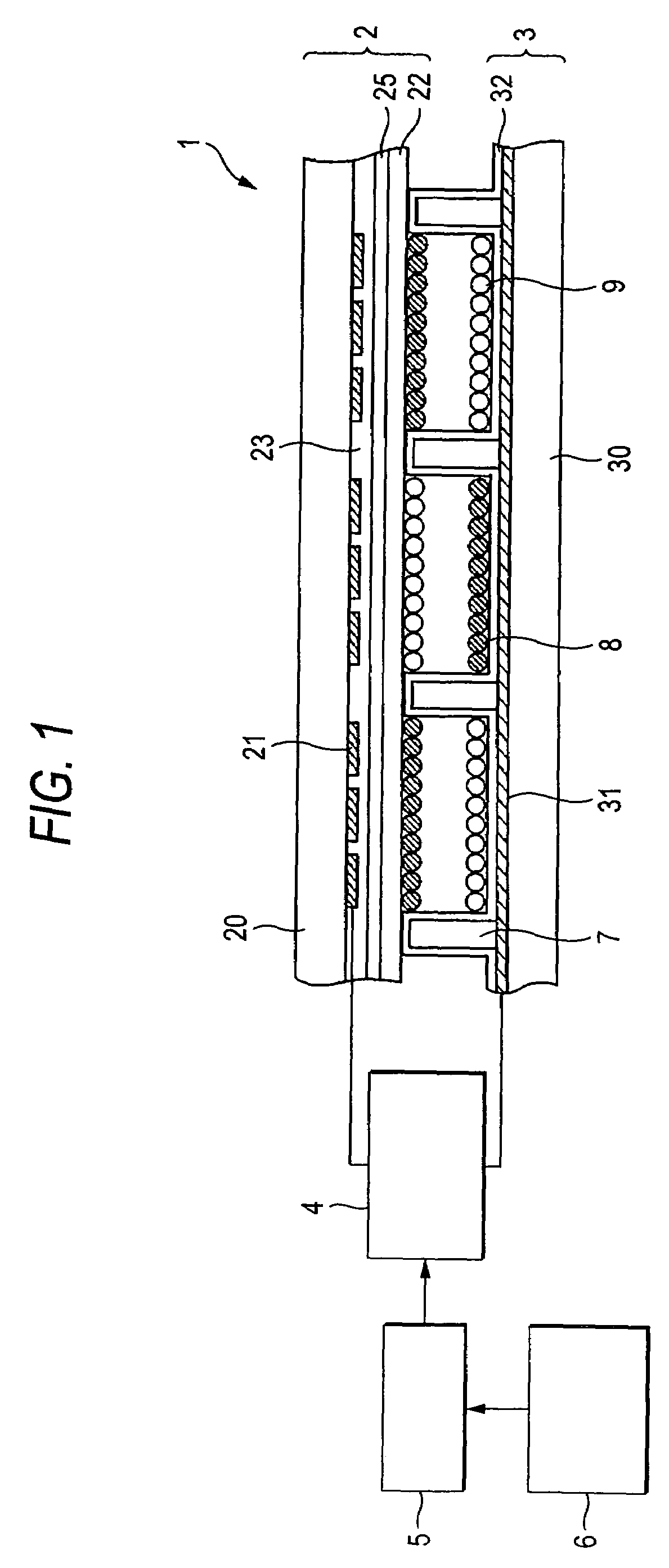

first embodiment

(Advantages of First Embodiment)

[0044]According to the first embodiment, the following advantages are provided:

[0045](a) As the insulating layer 22 is formed through the first bonding layer 25 having a Young's modulus smaller than the surface support substrate 20 and the insulating layer 22, if the insulating layer 22 has a thickness to secure a sufficient insulating property, when bending deformation, etc., is added, the first bonding layer works as a buffer material and it is made possible for the insulating layer 22 to flexibly follow the deformation of the surface support substrate 20, so that peeling does not occur.

[0046](b) The insulating layer 22 is thickened, whereby occurrence of pinholes of the insulating layer 22 caused by collision of the first and second particles 8 and 9 can be suppressed and a display failure of the image display medium 1 caused by lowering of the charge amounts of the first and second particles 8 and 9 can be prevented.

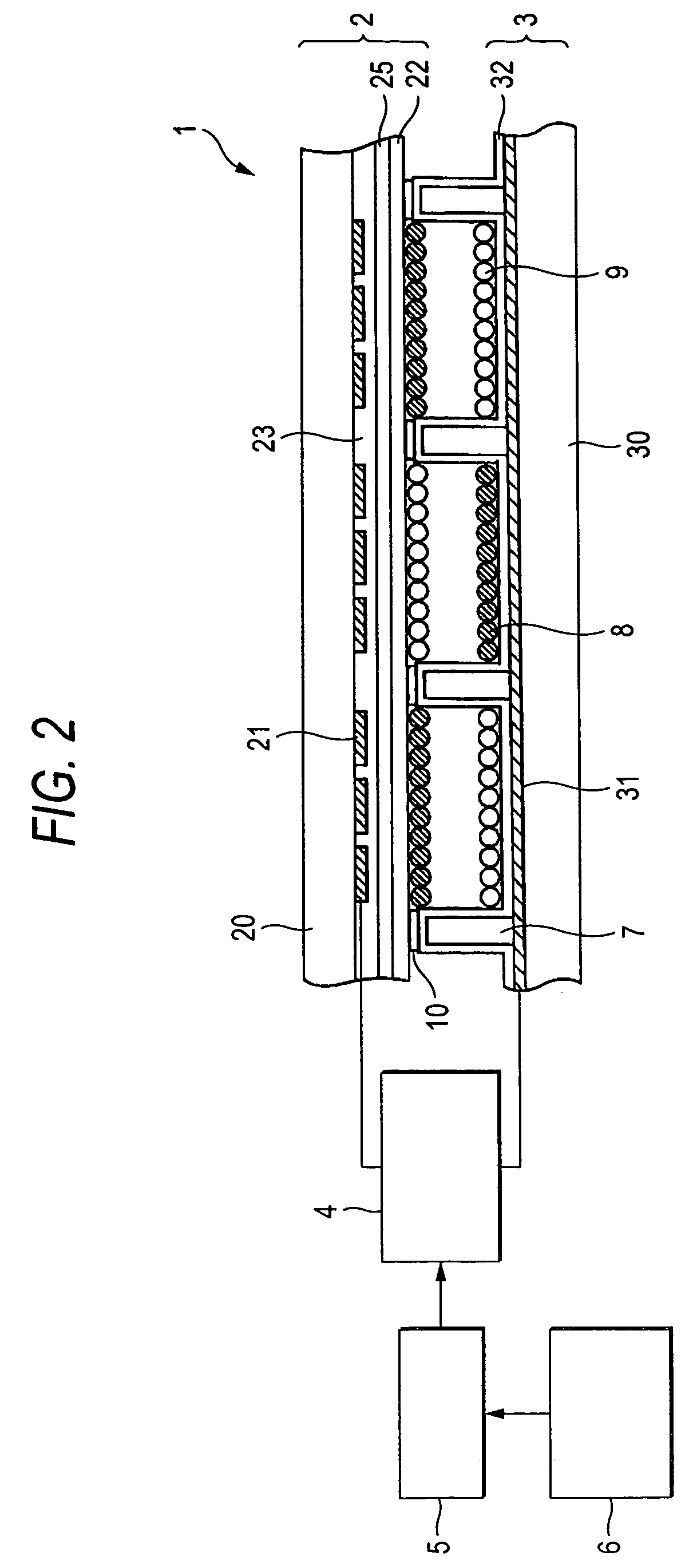

Second Embodiment

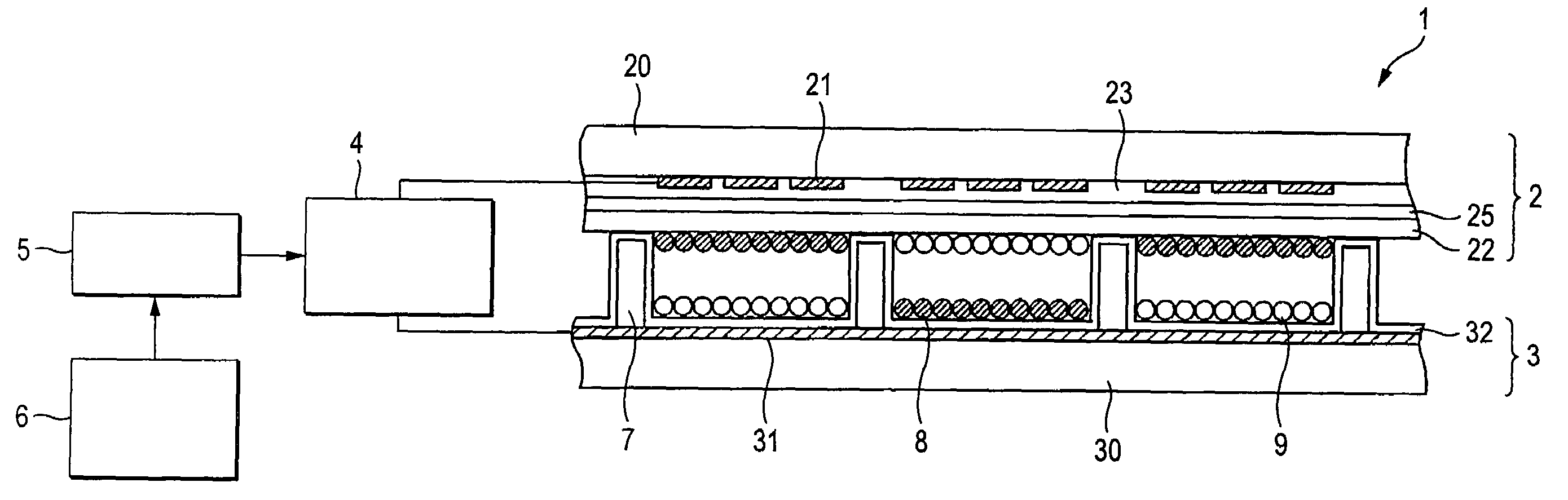

[0047]FIG. 2 i...

second embodiment

(Advantages of Second Embodiment)

[0048]According to the second embodiment, when the partition members 7 and the insulating layer 22 are bonded by the second bonding layer 10, peeling occurring between the partition members 7 and the insulating layer 22 can be prevented.

Other Embodiments

[0049]It is to be understood that the invention is not limited to the specific embodiments thereof described above and various modifications and changes can be made without departing from the spirit and the scope of the invention.

[0050]For example, in the description of the embodiments, the first and second particles 8 and 9 are charged by friction, but the invention is not limited to the mode.

[0051]In the description of the embodiments, the image display medium 1 is a toner display, but may be any other type of image display medium for displaying an image with particles.

[0052]In the description of the embodiments, the image display medium 1 produces monochrome binary display, but may be an image disp...

first example

[0057]In a first example, four types of image display media 1 each having a similar configuration to that in the first embodiment were manufactured by changing the thickness of the insulating layer 22, and the charge amount of the mixed particles of white and black particles and the display density of each image display medium 1 were evaluated.

[0058]The thicknesses of the insulating layers 22 of the four types of image display media 1 were 0 (no insulating layer), 77 nm, 380 nm, and 1900 nm. Other components were common to the four types of image display media 1. The height of the partition member 7 was 200 μm, the thicknesses of the insulating film 32 was 1000 nm, and the diameter of a white particle charged negatively and the diameter of a black particle charged positively were each about 10 μm.

[0059]Transparent and colorless UV curable resin with tensile bonding force 80 kg / cm2 and Young's modulus 100 kg / cm2 was used as the first bonding layer 25. For the UV curable resin, curing...

PUM

| Property | Measurement | Unit |

|---|---|---|

| light transmittance | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com