Metal tube and ring rolled seal gasket and manufacturing method thereof

A technology of sealing gasket and manufacturing method, applied in the direction of engine sealing, engine components, mechanical equipment, etc., can solve the problems of narrow application range, limited pressure resistance and compression resilience, loss of sealing performance, etc. The effect of small size, expanding the scope of application and prolonging the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

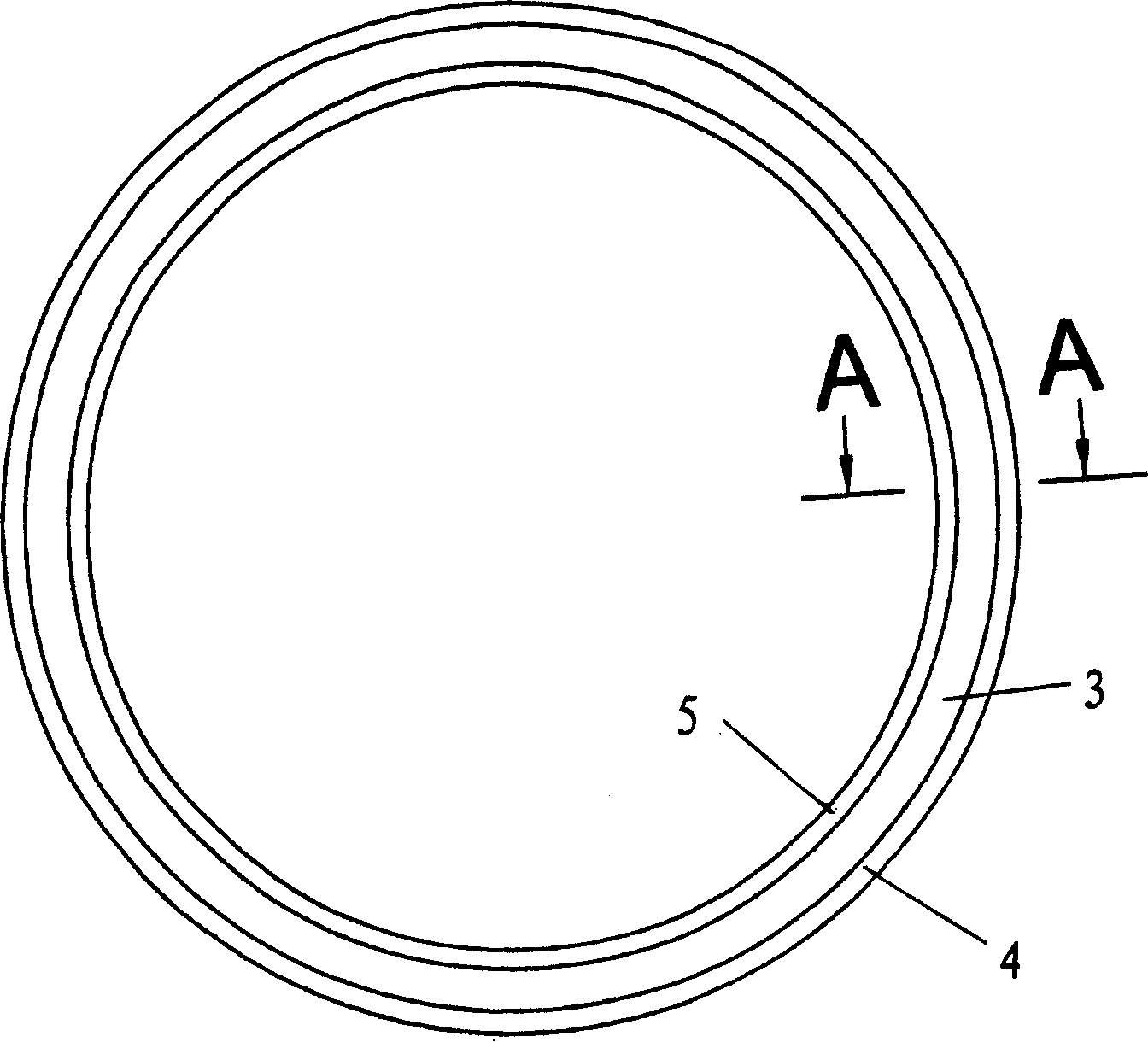

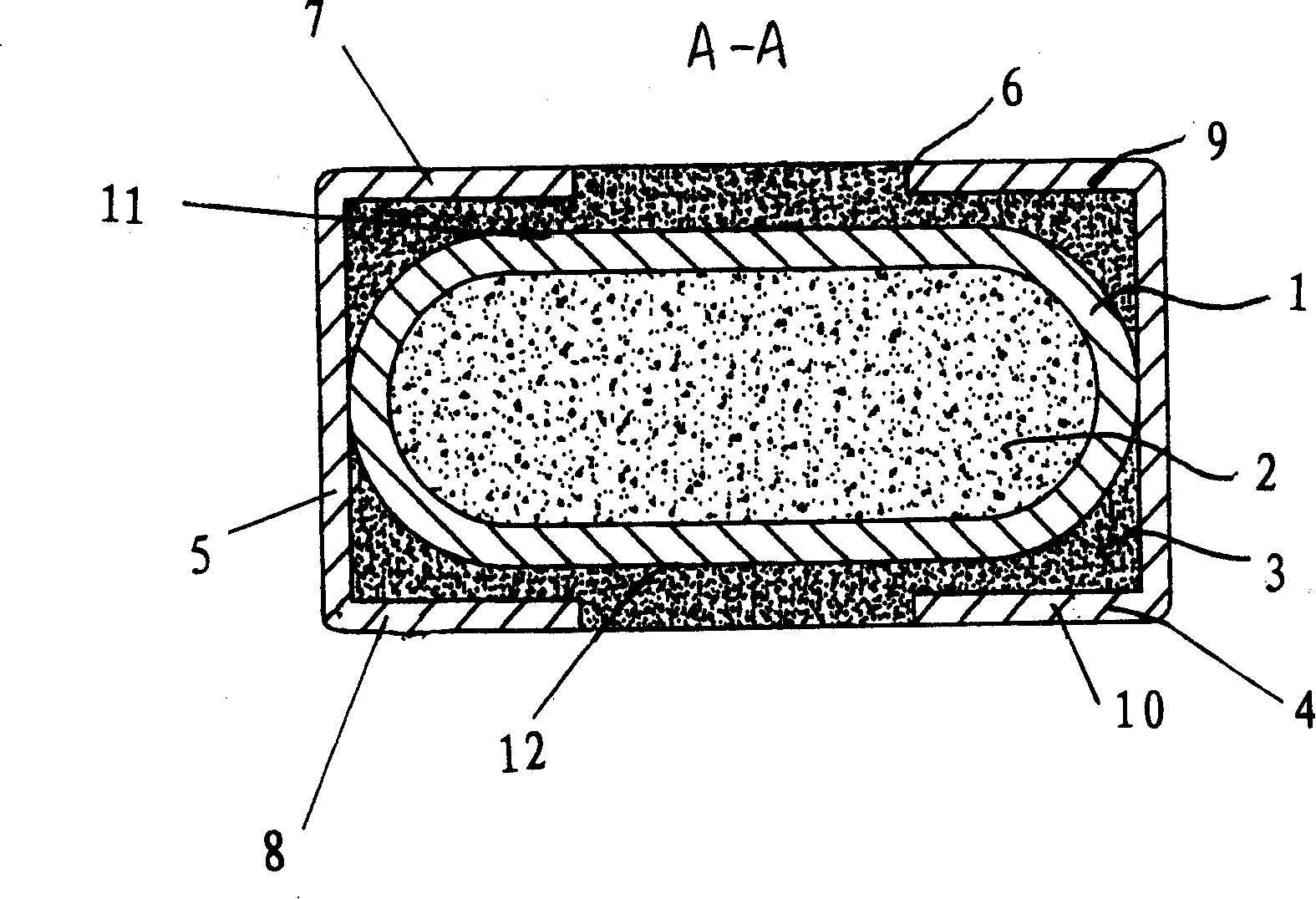

[0022] See attached figure 1 to attach figure 2 , a metal pipe ring rolling sealing gasket, which includes an annular metal pipe 1, a flexible sealing filler 2 filled in the inner cavity of the metal pipe 1, and coated on the surface of the metal pipe 1 The cladding layer 3, the outside of the cladding layer 3 is provided with a cladding outer ring 4, the inside of the cladding layer 3 is provided with a cladding inner ring 5, and the metal pipe 1 covered with the cladding layer 3 is clamped Immediately between the cladding outer ring 4 and the cladding inner ring 5, the radial section of the metal pipe 1 is a closed ring structure, and the metal pipe 1 is along the circumference of the gasket. The directions are connected end to end to form a sealed pipe ring. The material of the metal pipe 1 is one of carbon steel, stainless steel, copper, aluminum, Monel, Inconel, titanium; the flexible sealing filler 2 is graphite, fiber, One or a mixture of two or more of polytetraflu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap