Battery box with waterproof structure

A technology of waterproof structure and battery box, which is applied in the direction of structural parts, battery pack parts, battery and its environment isolation, etc. It can solve the problems of affecting the sealing performance, the gasket does not reach the compression amount, and the sealing failure, so as to improve the overall structural strength. , Guarantee compression sealing effect, reliable sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] A preferred embodiment of the present invention will be described in detail below with reference to the accompanying drawings.

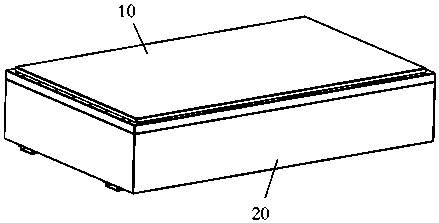

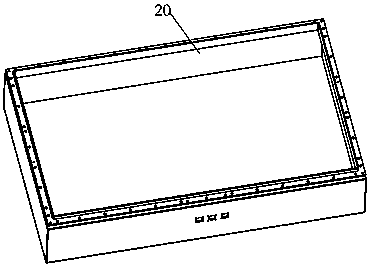

[0023] Such as figure 1 , 2 As shown in and 3, the battery box includes a battery box upper cover 10 and a battery box lower box body 20, a sealing strip 40 is arranged between the battery box upper cover and the edge of the battery box lower box body, and is passed through a fastener 30 to fix.

[0024] Such as Figure 4 and 5 As shown, in order to improve the structural strength of the battery box, the battery box upper cover 10 and the battery box lower box 20 adopt a flanging and bending structure, wherein the edge of the battery box upper cover 10 is bent downward twice and once outward The stepped structure of the flange forms the first upper cover lower bend 11 , the upper cover outer flange 12 and the second upper cover lower bend 13 connected in sequence. The edge of the lower box body 20 of the battery box adopts an overall inwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com