Water pressure fastening connecting type water supply automatic control system for passenger train

An automatic control system and fastening connection technology, applied in the field of passenger train water supply system, can solve the problems of increasingly prominent supply/demand contradiction, high water supply labor intensity, affecting other operations, etc., and increase the effective water supply time , Improve work efficiency and prolong the time of water supply

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with the embodiments and accompanying drawings.

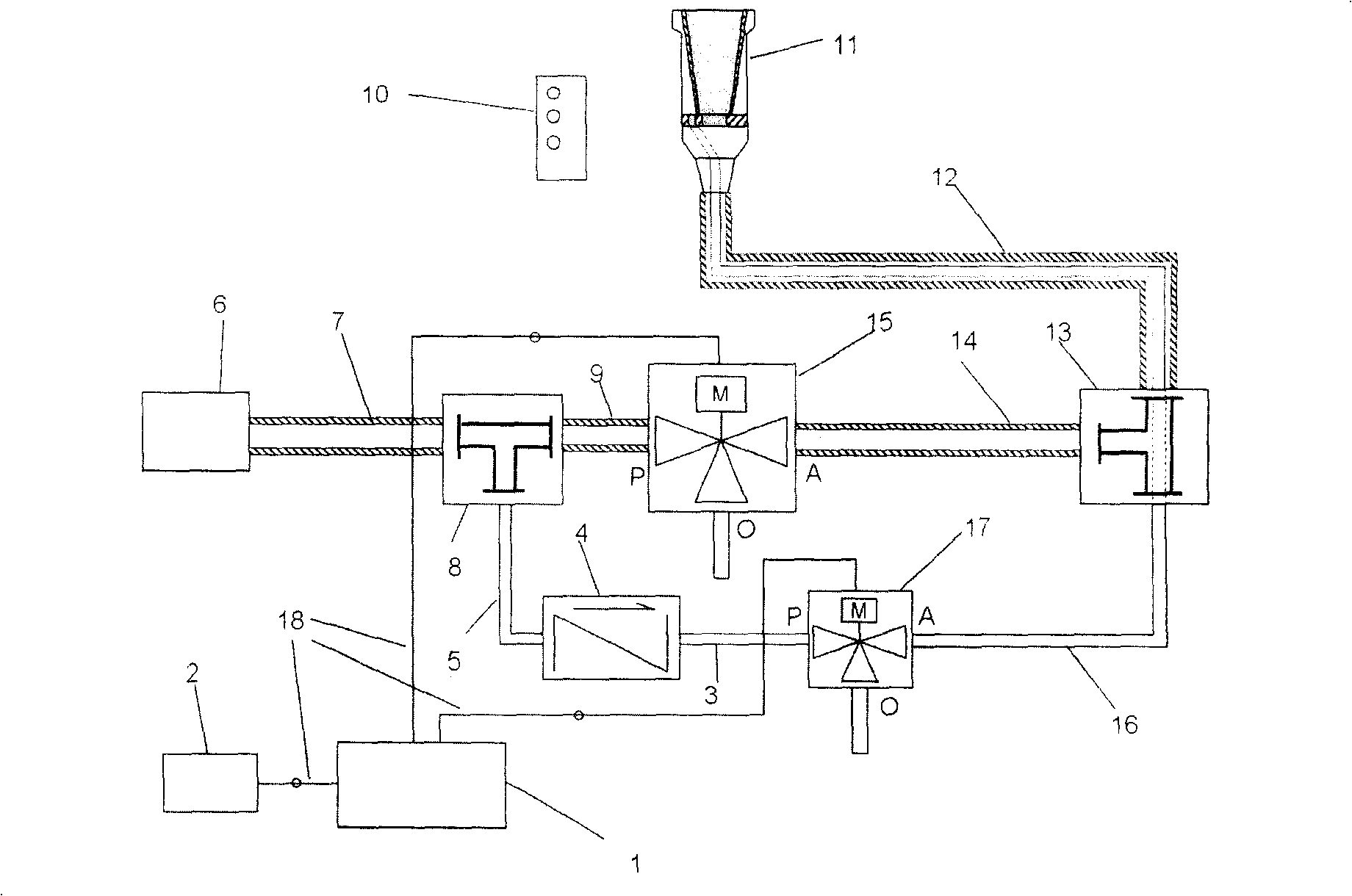

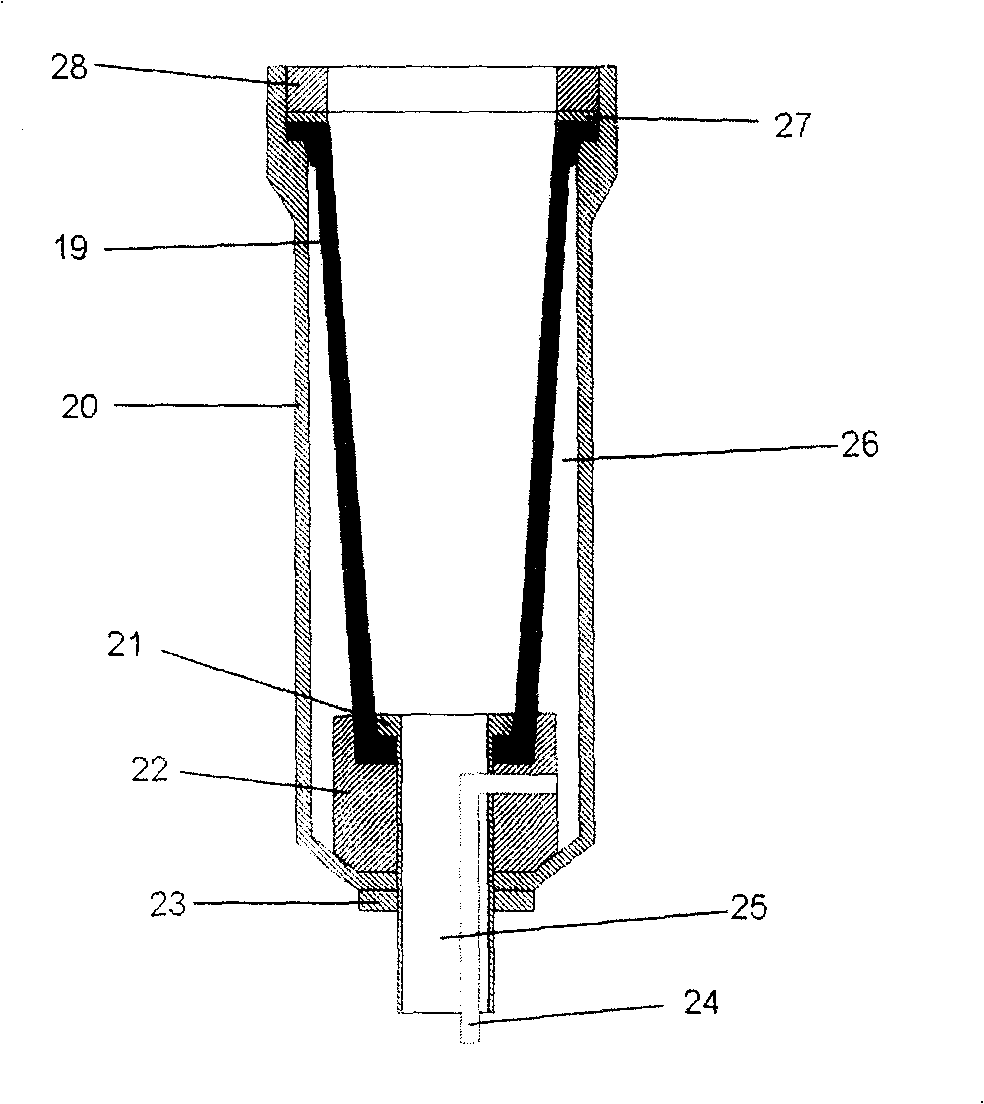

[0020] The structure of the present invention is as figure 1 As shown: it is mainly composed of a water pressure fastening type quick pipe joint 11, a water return device 4 in the control pipe, a water supply pipeline controlled by a two-position three-way solenoid valve, and a control device. Wherein: the upper end of the hydraulic fastening type fast pipe joint is connected with the water injection nozzle on the passenger train body, and the lower end is connected to one end of the first-stage tee 13 through the upper water pipe 12; the other two ends of the tee are connected through the second The water pipe 14, the second two-position three-way solenoid valve 15, the first water pipe 9, the second-stage three-way connection 8, and the water supply pipe 7 are connected to the water source 6, and the other end passes through the third control water pi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com