Water feeding pipe connector capable of being opened and closed manually

A technology for water pipe joints and water pipes, which is applied in the direction of pipes/pipe joints/fittings, hose connection devices, connections with fluid cut-off devices, etc. Mental burden and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the following will further explain how the present invention is implemented in conjunction with the accompanying drawings and specific implementation methods.

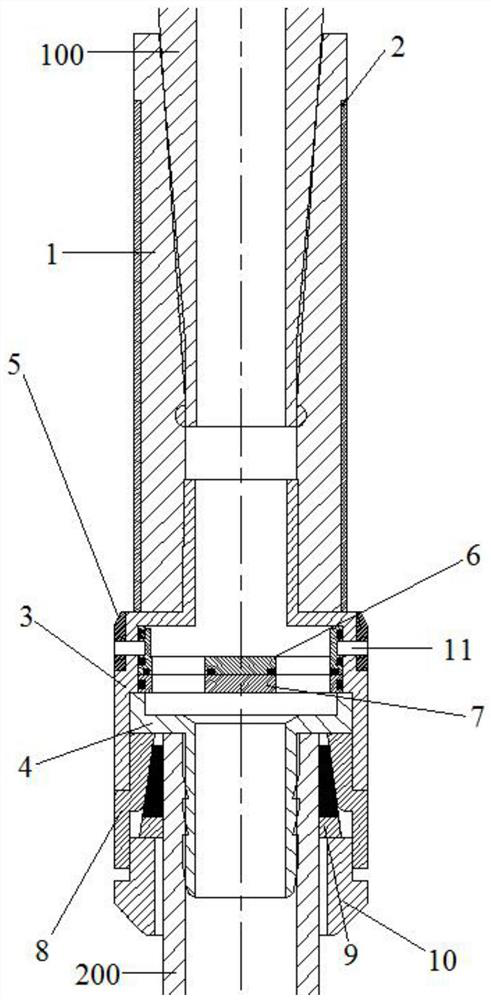

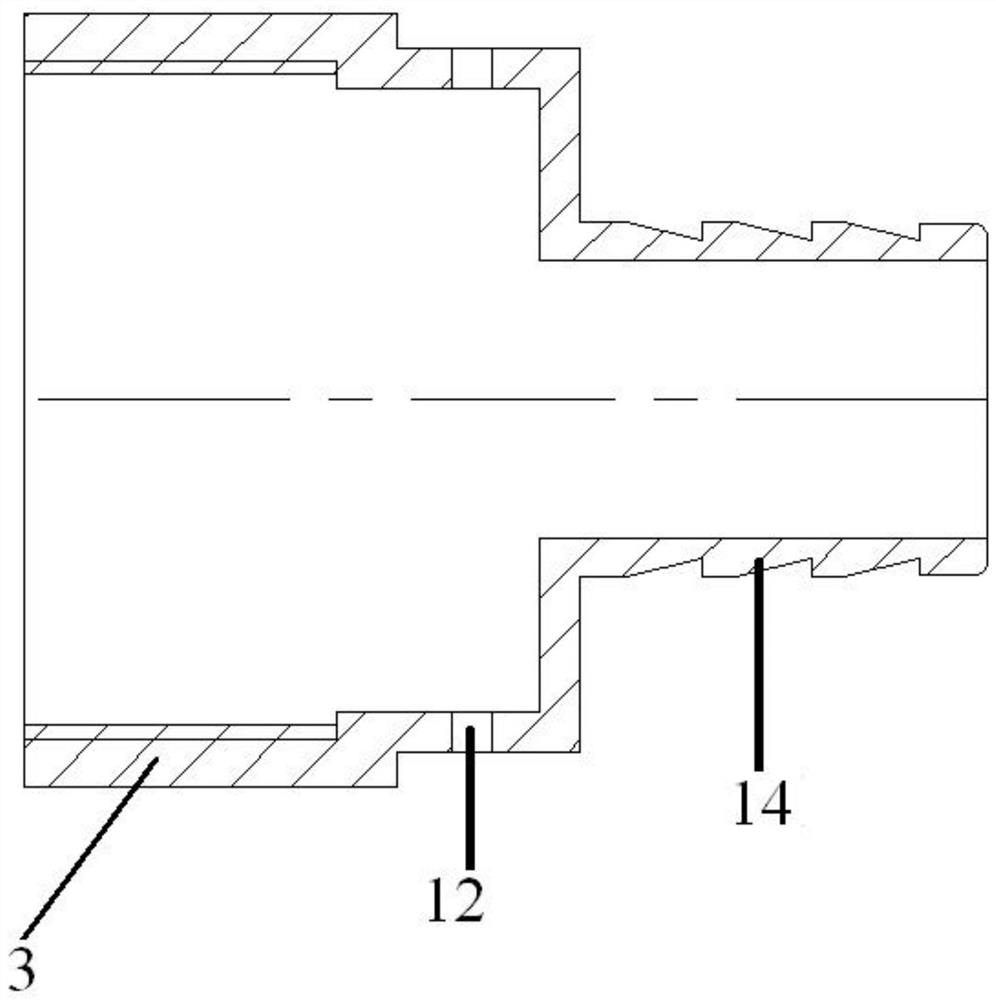

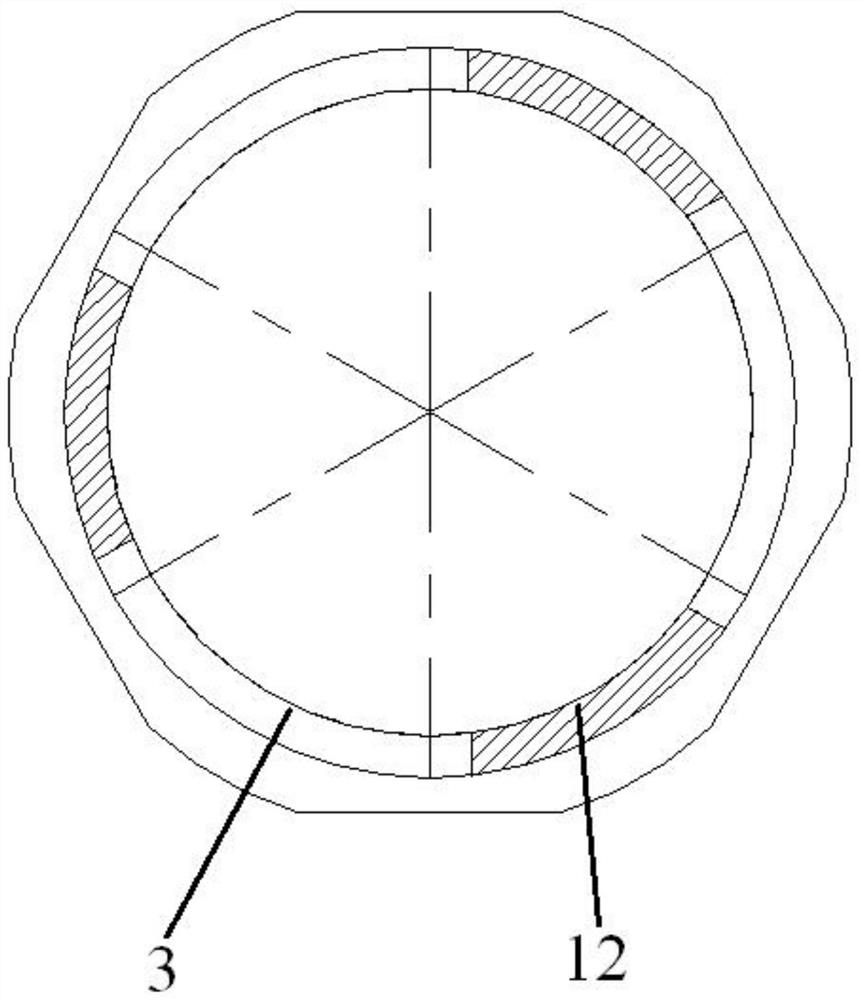

[0038] refer to Figure 1-Figure 8 As shown, the present invention provides a water supply pipe joint that can be opened and closed manually, which is used to connect the train water injection nozzle 100 and the water supply pipe 200 of the water supply equipment, including a joint body, a switch ring 5, a valve core 6, and a water sealing plate 7 and the transmission part 11; the two ends of the joint main body are respectively connected with the train water injection nozzle 100 and the upper water pipe 200; the switch ring 5 is set on the outside of the joint main body, the valve core 6 and the water sealing plate 7 are all arranged on the inner side of the joint main body, and the va...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com