Degradable elastomers for chewing gum base

A technology of elastomers and monomers, applied in the field of chewing gum, can solve problems such as pollution that has not been significantly solved

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

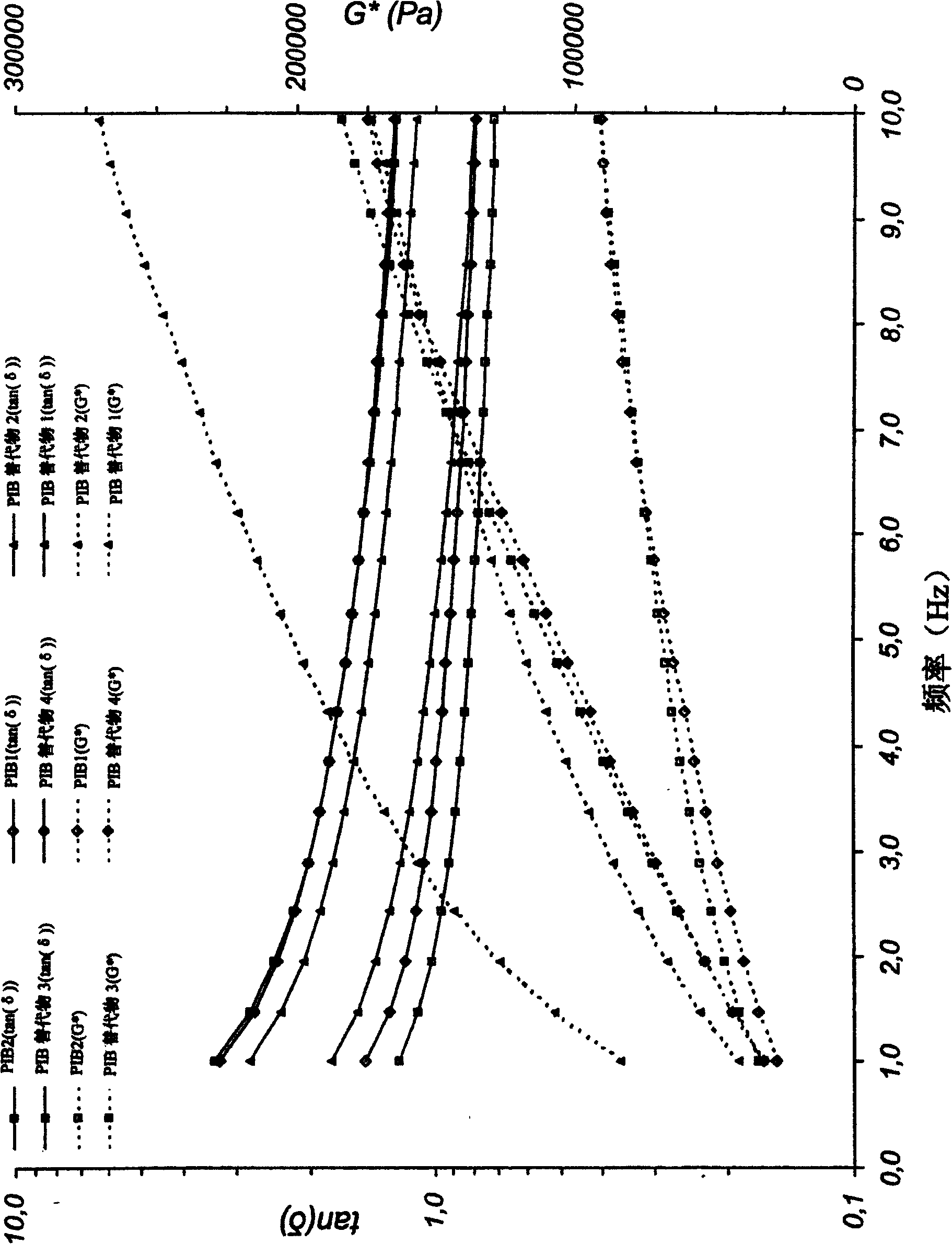

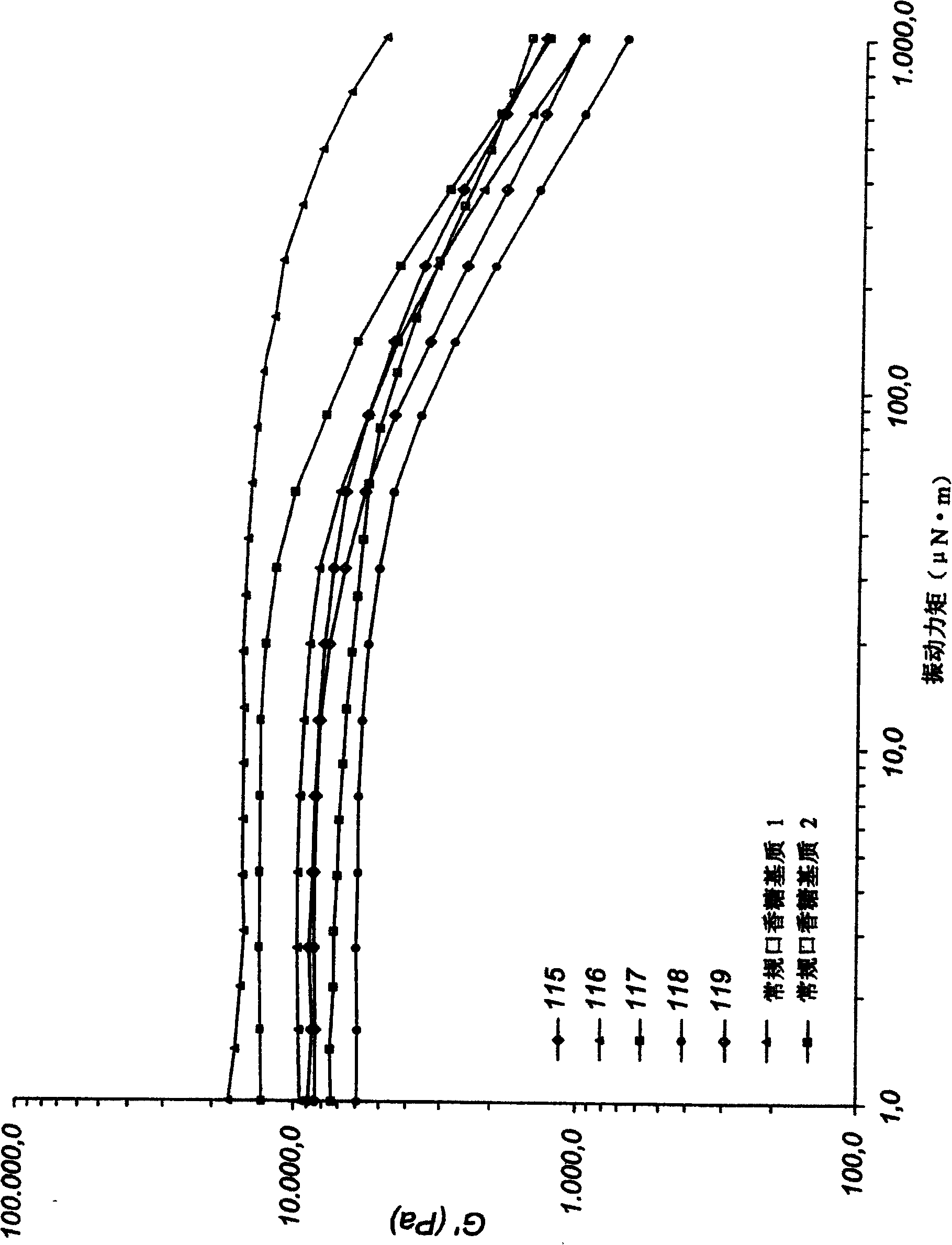

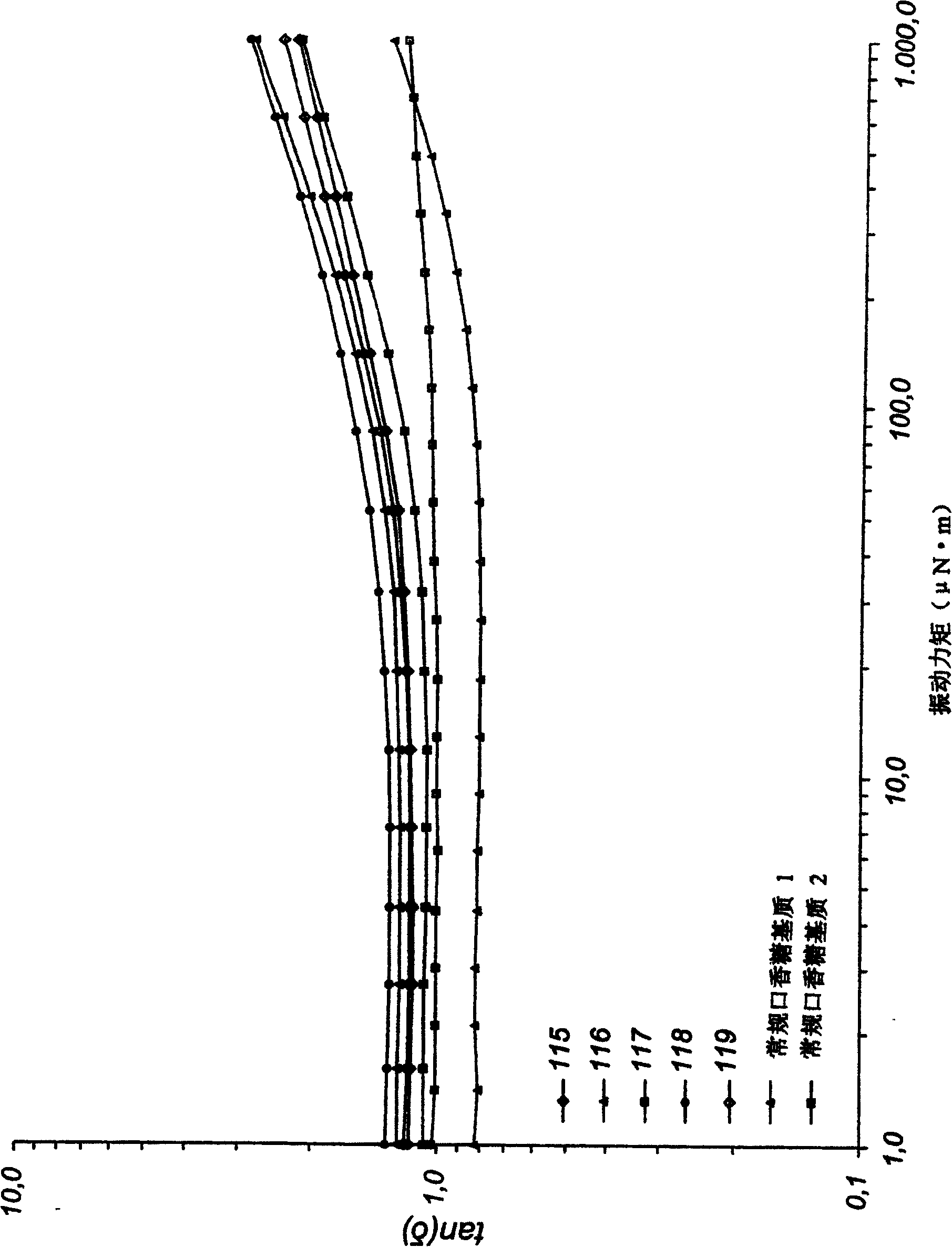

[0017] A strategy for the development of gum base elastomers has been to develop polymers with low glass transition temperatures that are either completely amorphous or slightly crystalline with a crystalline melting point below room temperature.

[0018] A preferred route to prepare such polymers is to use a combination of two or more low Tg monomers such that these different repeat units hinder crystallization.

[0019] Accordingly, one aspect of the present invention relates to polyester polymers comprising polymers obtained by the polymerization of two or more different cyclic ester monomers, wherein the cyclic ester monomers have a low glass transition temperature (Tg), and the polyester polymers have The glass transition temperature (Tg) is in the range of (-20°C)-(-80°C).

[0020] Preferably, the cyclic ester monomer is selected from 4-membered lactone, 5-membered lactone, 6-membered lactone, 7-membered lactone, 8-membered lactone, 5-membered ring carbonate, and 6-membe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com