Chemical and mechanical grinding method for aluminium

A technology of chemical machinery and grinding methods, which is applied in grinding devices, grinding machine tools, metal processing equipment, etc., and can solve problems such as uneven thickness of insulating layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

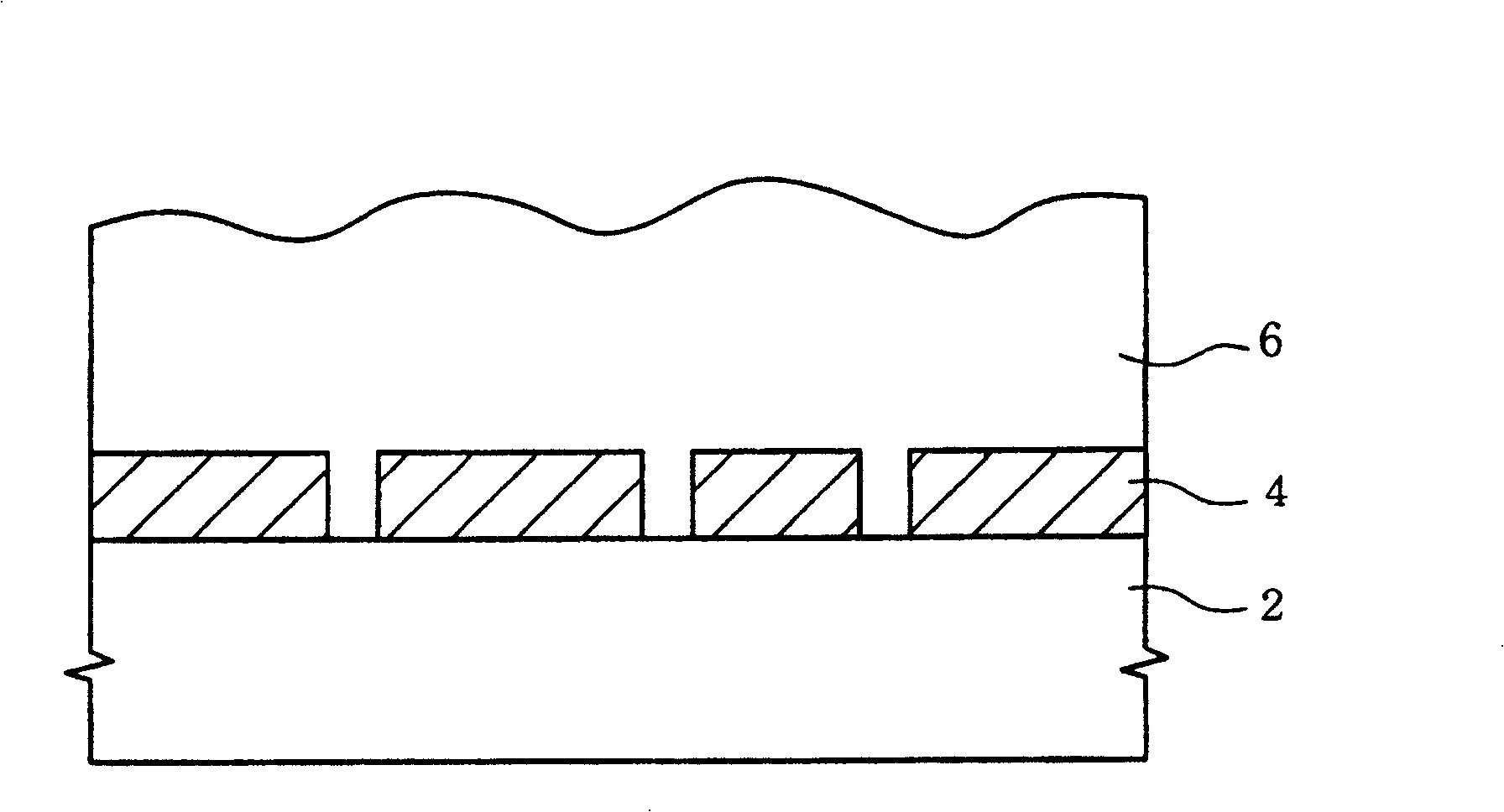

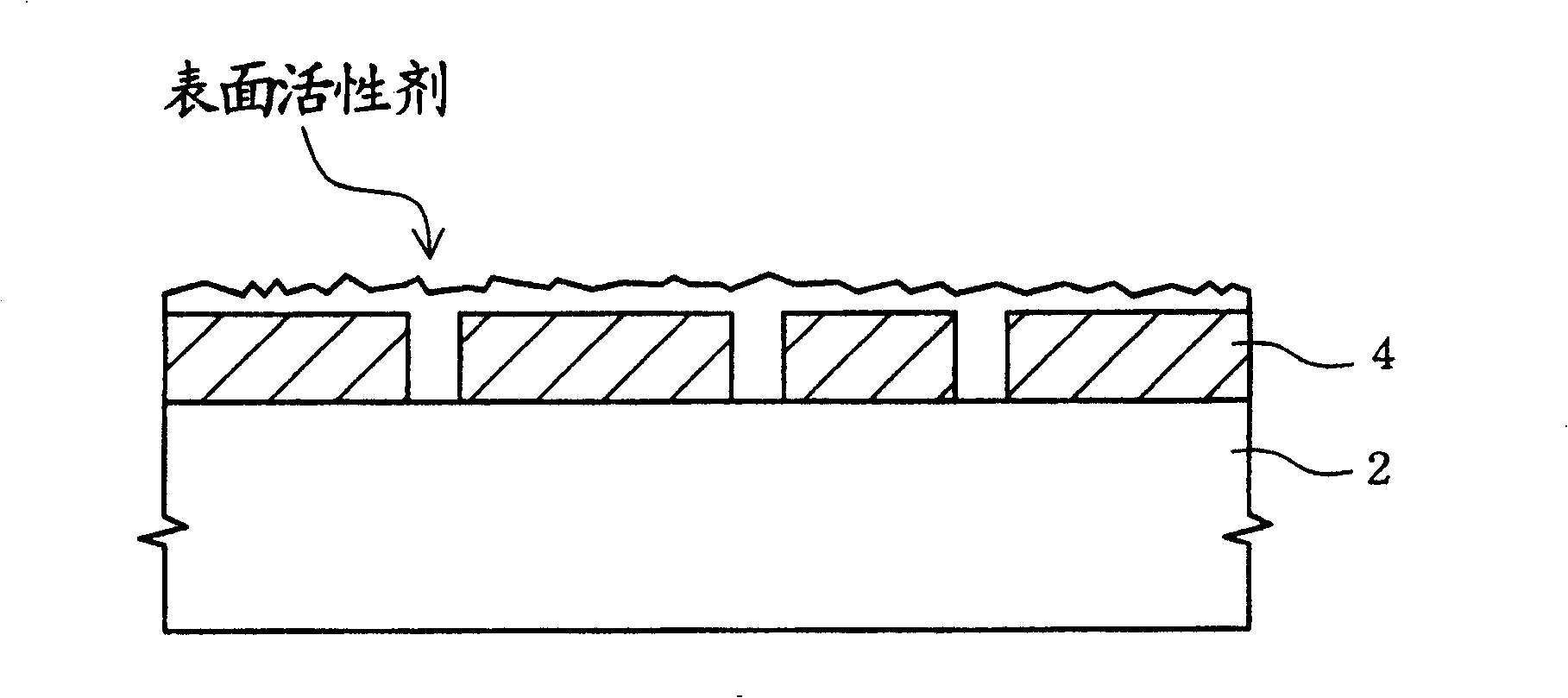

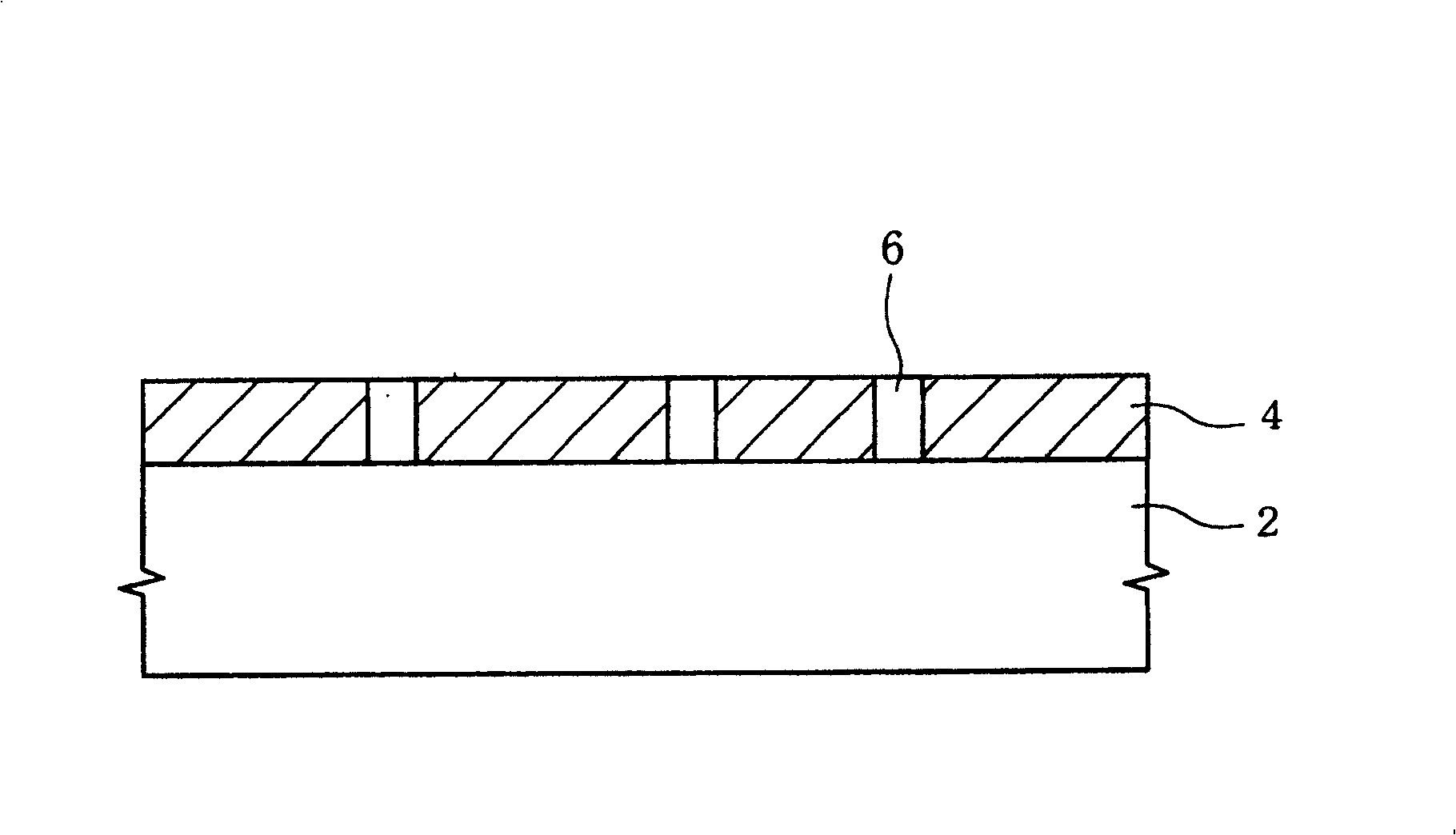

[0012] Please refer to the manufacturing process of the present invention figure 1 , first provide a semiconductor substrate (substrate) 2, in a preferred embodiment, the substrate 2 is a single crystal silicon crystal plane or . Respectively fabricate related wells in the semiconductor substrate 2 and its related film layer on the substrate, the above is not the main point of the present invention, so it will not be repeated. The aluminum pattern 4 is fabricated on the substrate by lithography, and then an insulating layer 6 is formed to be stacked on the above-mentioned aluminum metal 4 pattern by conventional technology. The oxide is used as the filling substance of the insulating material. Generally, after the deposition is completed, the oxide is ground by a chemical mechanical grinding method to produce insulation between aluminum and metal. The important feature of the present invention is to incorporate a surfactant (Surfactant) into the abrasive, which can be adsorb...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com