Chemical mechanical polishing slurry composition for polishing tungsten pattern wafer and method for polishing tungsten pattern wafer using same

A chemical-mechanical and slurry-abrasive technology, which is applied in the direction of polishing compositions containing abrasives, chemical instruments and methods, and other chemical processes, can solve problems such as the reduction of the grinding rate of the tungsten layer, and achieve the effect of improving the stability of the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

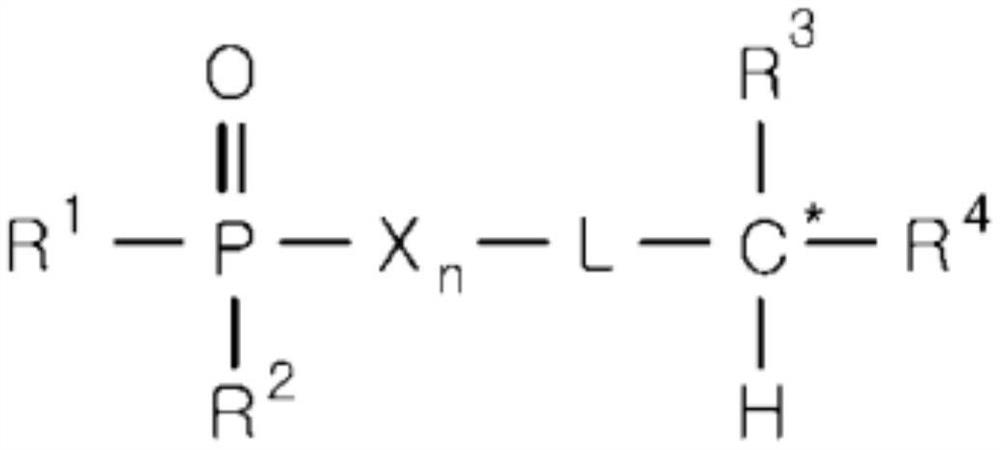

Method used

Image

Examples

example 1

[0099] This example shows the effect of polycarboxylic acids on the stability of slurry compositions comprising compounds of Formula 1. The components of the composition are shown in Table 1. The abrasive was silica particles having an average particle size (D50) of about 95 nm and charged at about 35 mV. Use deionized water as solvent. From the particle size data shown in Table 2, it can be seen that the polycarboxylic acid-containing slurry composition according to the present invention exhibits better stability than the polycarboxylic acid-free slurry composition. After storing in an oven at 40° C. for 7 days, the particle size of the slurry particles stored at high temperature was measured using a particle analyzer (Zetasizer Nano, Malvern Co., Ltd.). particle size.

[0100] Table 1

[0101]

[0102] Table 2

[0103] slurry Types of Primary particle size (nm) Particle size after storage at high temperature (nm) 1-A this invention 95 99 1-...

example 2

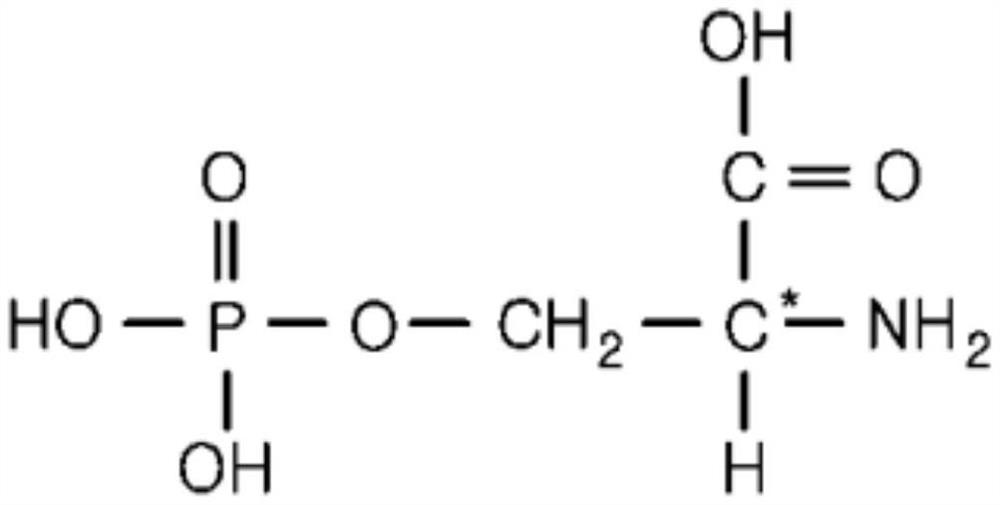

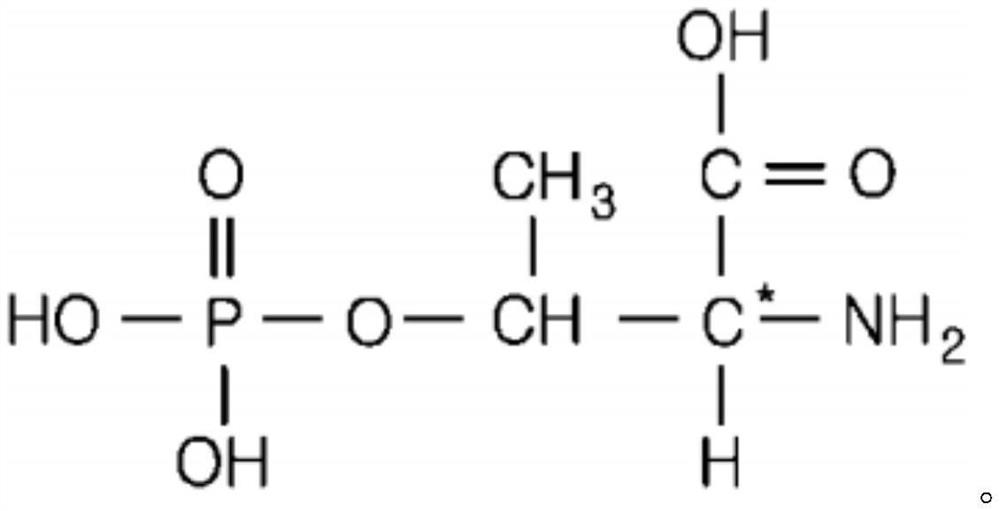

[0105] This example shows the effect of compounds of formula 1 on tungsten etch (corrosion) rate and tungsten grinding rate. The components of the composition are shown in Table 3. From the tungsten etching (corrosion) rate shown in Table 4, it can be seen that the slurry composition containing the compound of formula 1 has lower tungsten etching (corrosion) than other compositions not containing the compound of formula 1 or containing phosphorus-containing functional groups rate. In addition, it can be seen from the tungsten grinding rate shown in Table 4 that the phosphorus-containing amino acid corresponding to the compound of formula 1 exhibits a lower tungsten etching (corrosion) rate and a higher tungsten grinding rate than other amino acids. Furthermore, as shown in Table 4, the phosphorous-containing amino acid corresponding to the compound of Formula 1 allows a higher tungsten grinding rate than the phosphorous-containing compound and the amino acid when used in the ...

example 3

[0111] This example shows the effect of compounds of formula 1 on tungsten dishing. As can be seen from the tungsten depressions shown in Table 5, the slurry composition containing the compound of Formula 1 exhibited smaller tungsten depressions than other compositions not containing the compound of Formula 1 or containing phosphorus-containing functional groups.

[0112] table 5

[0113]

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com