Abrasive and method for producing abrasive

A technology of abrasive layer and abrasive grains, used in the manufacture of tools, abrasives, metal processing equipment, etc., can solve the problems of reduced grinding rate, surface pressure, easy to fall into the groove, etc. reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0114] The present invention is not limited to the embodiment, and various modifications and modifications can be implemented in the embodiment, in addition to the manner.

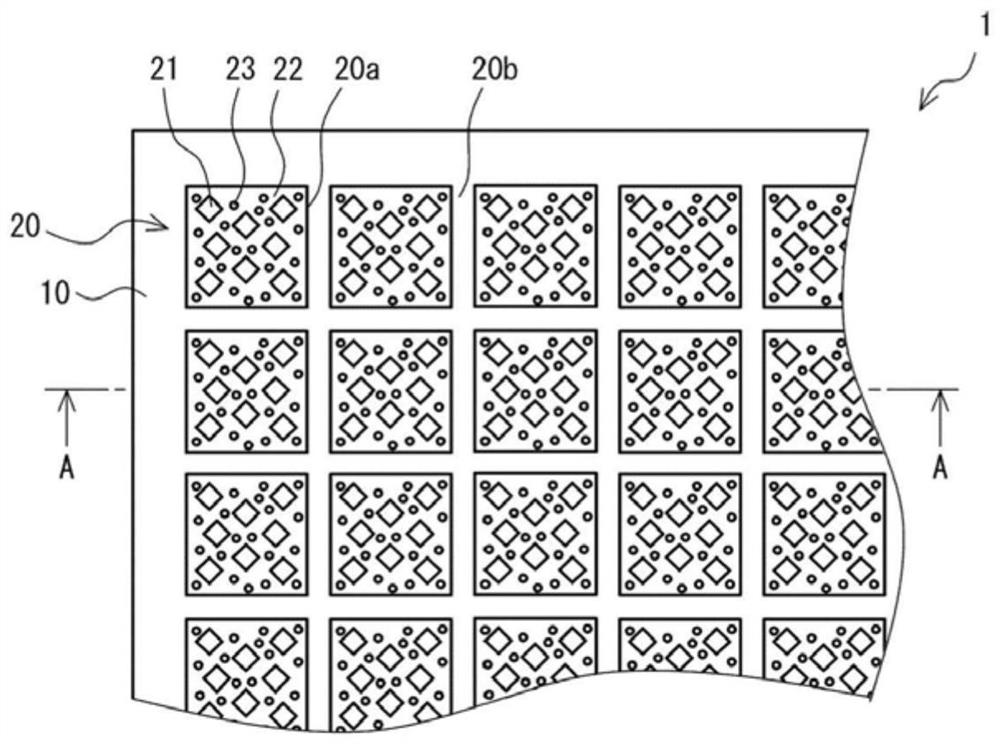

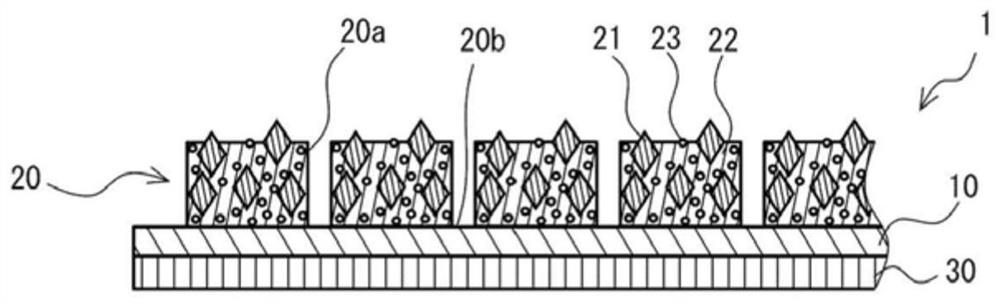

[0115] In the above embodiment, the case where the abrasive portion is a block pattern, but the abrasive portion is not limited to the block pattern. That is, the plurality of abrasive portions can also be different shapes or are arranged irregularly. However, the grinding portion is preferably a square pattern.

[0116] In the present embodiment, the case where the abrasive portion contains a filler, but the filler is not necessary to constitute a component, and the abrasive material having a film containing the filler is also within the intent of the invention.

[0117] In the above embodiment, the case where the abrasive material has a next layer, but the layer is not necessary to constitute a component, may be omitted. In the case where the abrasive material does not have a layer, the next layer attachment...

Embodiment 1

[0125] The "SINO CRYSTAL Diamond" "SINO Crystal Diamond", "SCMD-C12-22", an average particle size of 16 μm, as a filler (Al 2 O 3 , "LA4000", average particle size of Pacific Rundum Co., Ltd., averaged (Aerosil), "Aerosil 200"), as well as a binder Epoxy resin (JER828 "of Mitsubishi Chemical Co., Ltd.) was mixed, and the content of diamond grinding in solid composition became 3% by volume, and the content of the filler was 71% by volume, as well as the content of gas phase silica. 5% by volume is adjusted to obtain coating liquid.

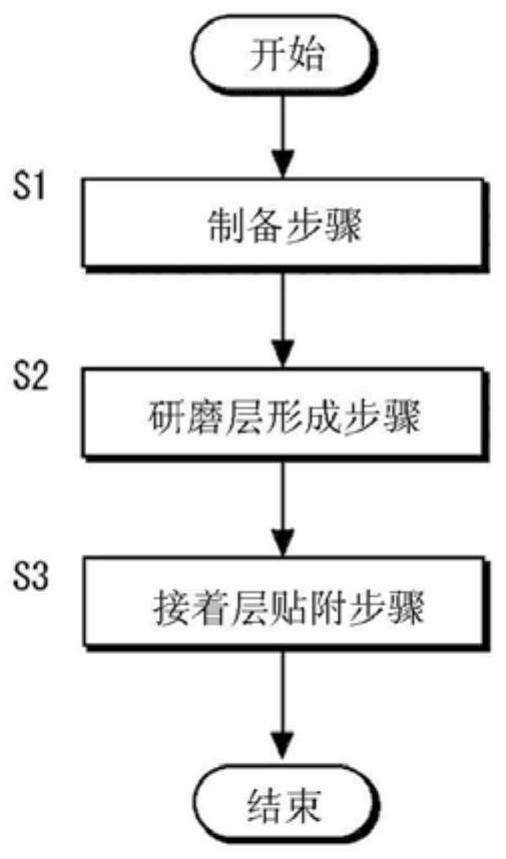

[0126] Preparing a substrate (an average thickness of 300 μm) as a main component as a heat-resistant resin as a substrate, using the coating liquid on the surface of the substrate using printing. As the pattern of printing, a circular shape having a diameter of 6 mm is used in a surface of 44% in size (an average area of 28.27 mm). 2 The opening portion, a fluorine resin having a average thickness of 1000 μm. Furthermore, the opening is a square pat...

Embodiment 2

[0130] The amount of coating is adjusted in such a manner that the average thickness of the abrasive portion is 300 μm, and the abrasive material of Example 2 is obtained in the same manner as in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| area | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com