Liquid detection device, liquid container using the same and liquid ejection apparatus

A technology for detection devices and liquid containers, applied to liquid level indicators for physical variable measurement, printing, etc., can solve problems such as difficulty in ensuring airtightness, inability to accurately detect ink remaining, false detection, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

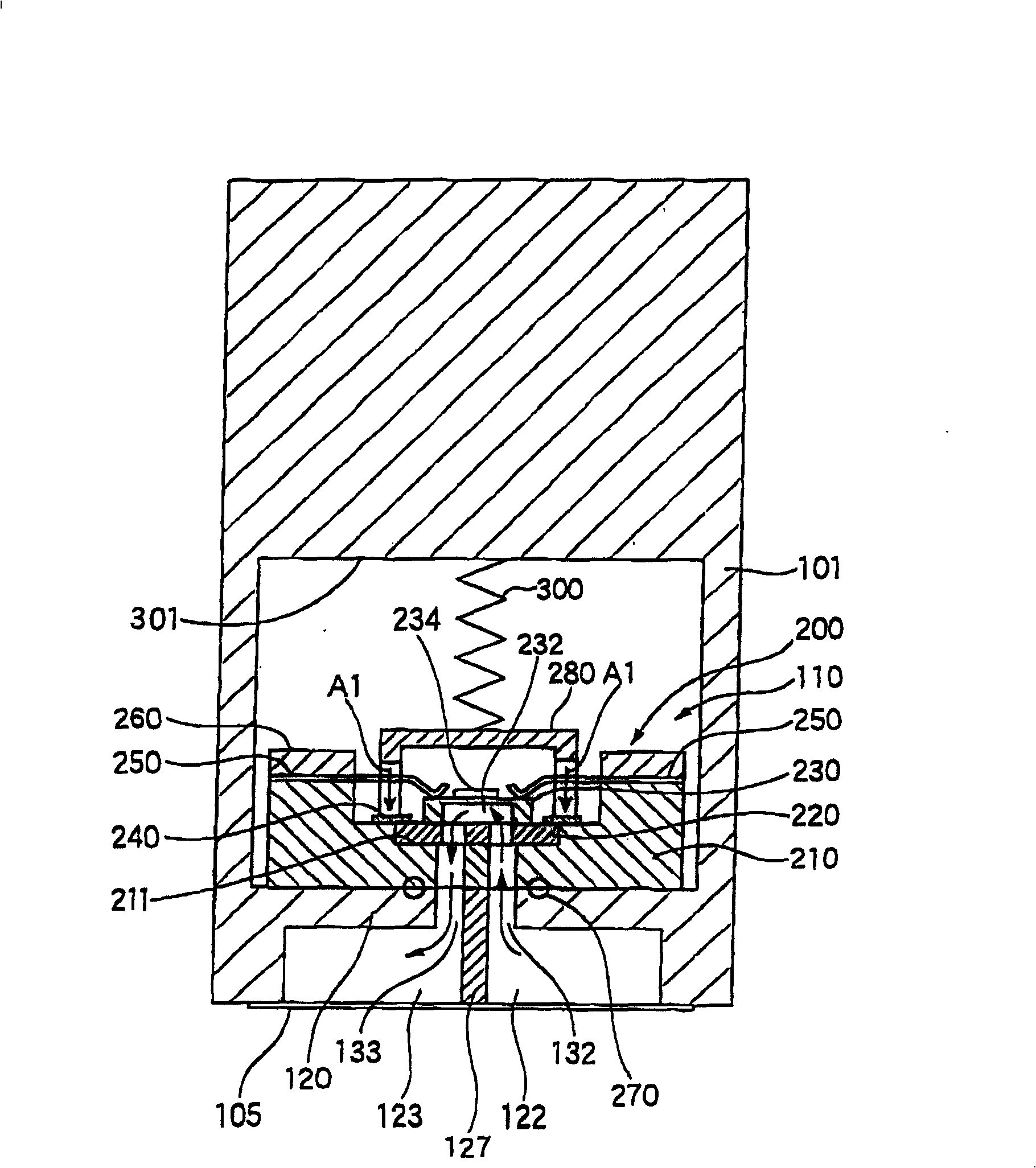

[0045] Next, liquid detection devices according to various embodiments of the present invention will be described with reference to the drawings.

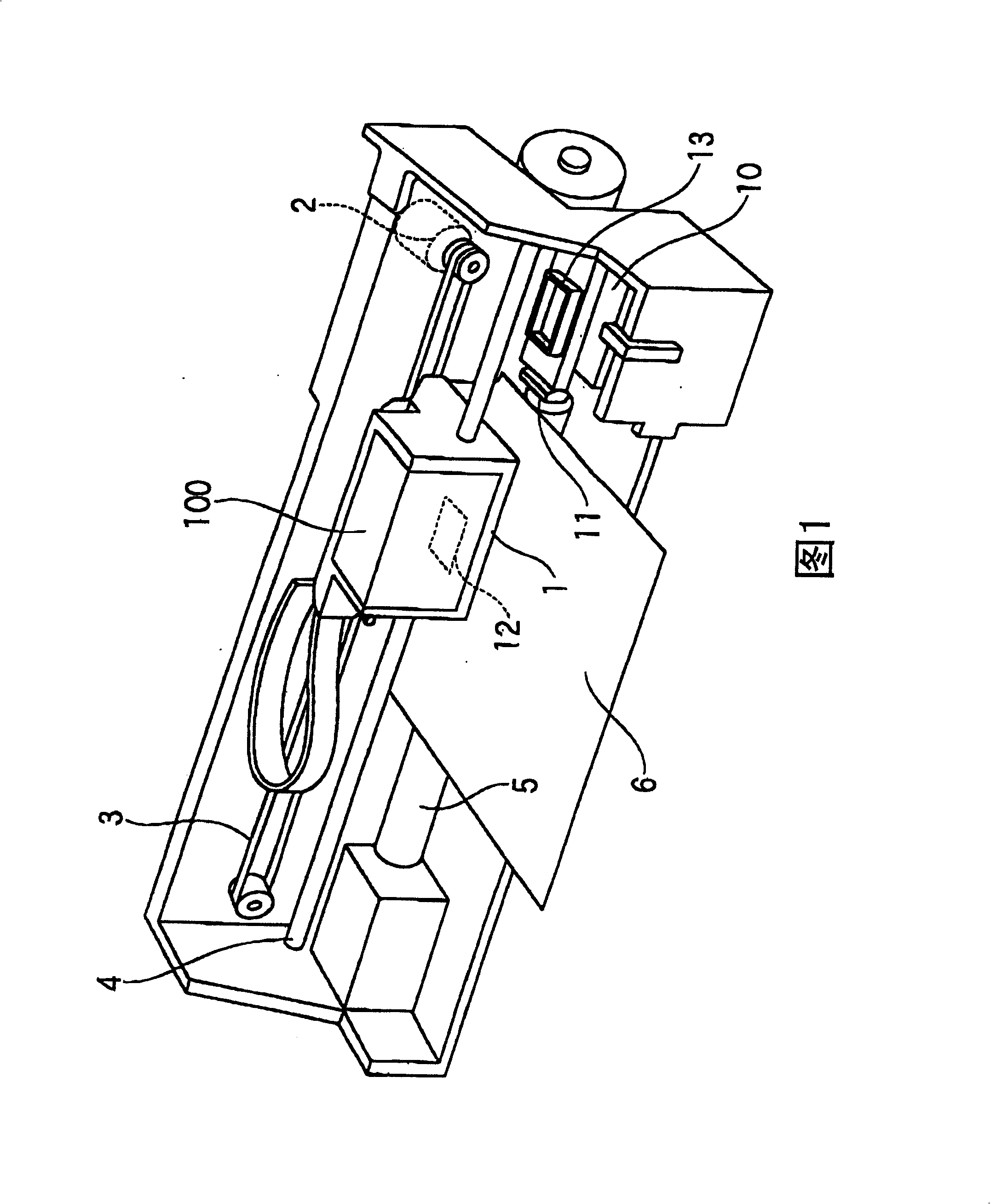

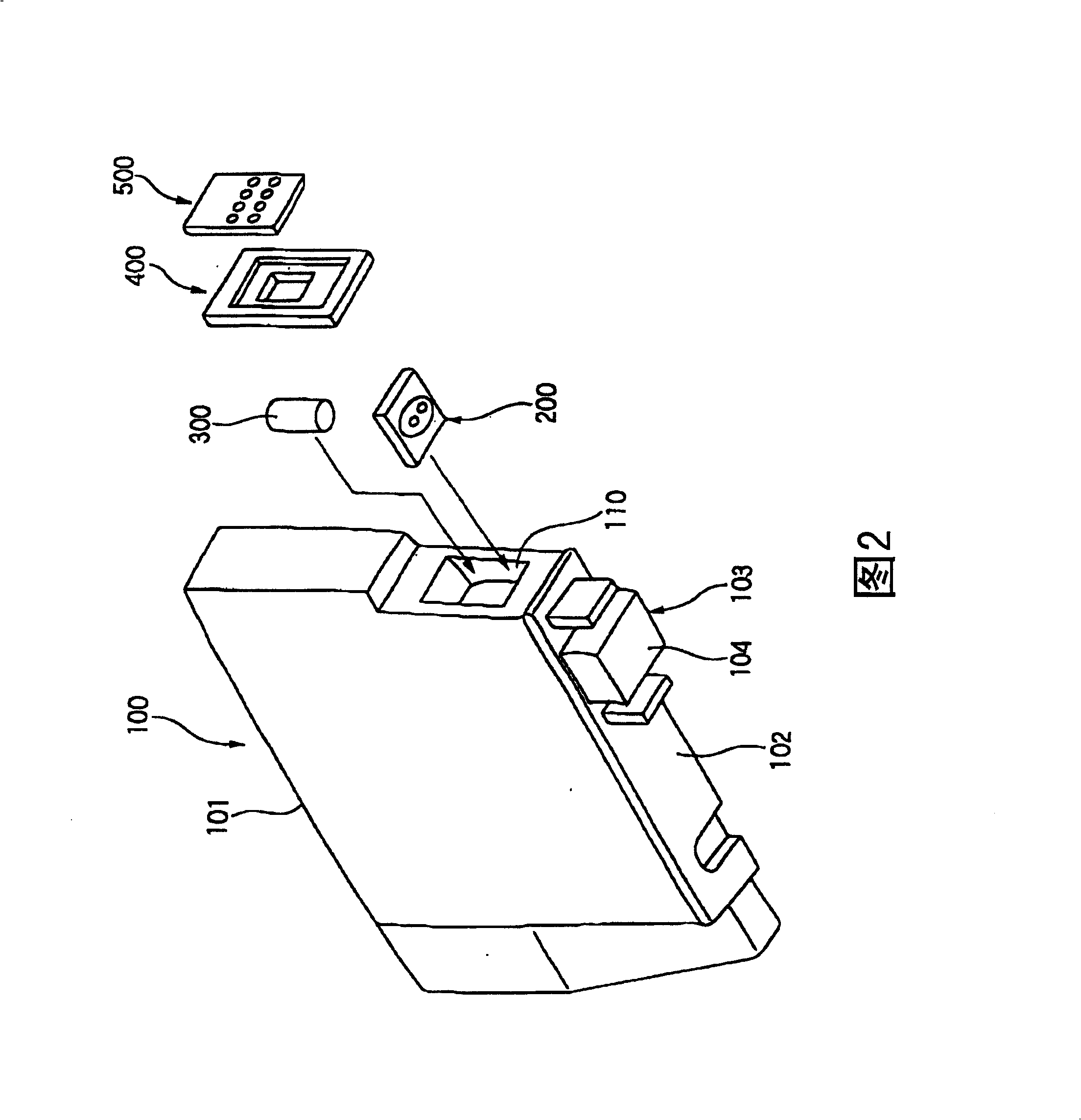

[0046] FIG. 1 shows a schematic configuration of an ink jet recording device (liquid ejecting device) using an ink cartridge (liquid container) having a liquid detection device according to a first embodiment. Reference numeral 1 in FIG. 1 denotes a carriage, and the carriage 1 reciprocates in the axial direction of the platen 5 under the guidance of the guide member 4 by the timing belt 3 driven by the carriage motor 2 .

[0047] An inkjet type recording head 12 is attached to the side of the carriage 1 facing the recording paper 6 , and a detachable ink cartridge (liquid container) 100 for supplying ink to the recording head 12 is attached to the upper portion thereof.

[0048] In the non-printing area of the recording device, that is, at the initial position (right side in the figure), a cap member 13 is arranged, and when the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com