Array electrode type flat plate wall micro-cavity generating device

A technology of array electrode and generating device, which is applied in the field of changing the inherent hydrodynamic characteristics of the ship hull, and the micro-cavitation generating device on the wall of flat sample, can solve the problems such as the influence of drag reduction rate, and achieve the effect of controllable formation speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

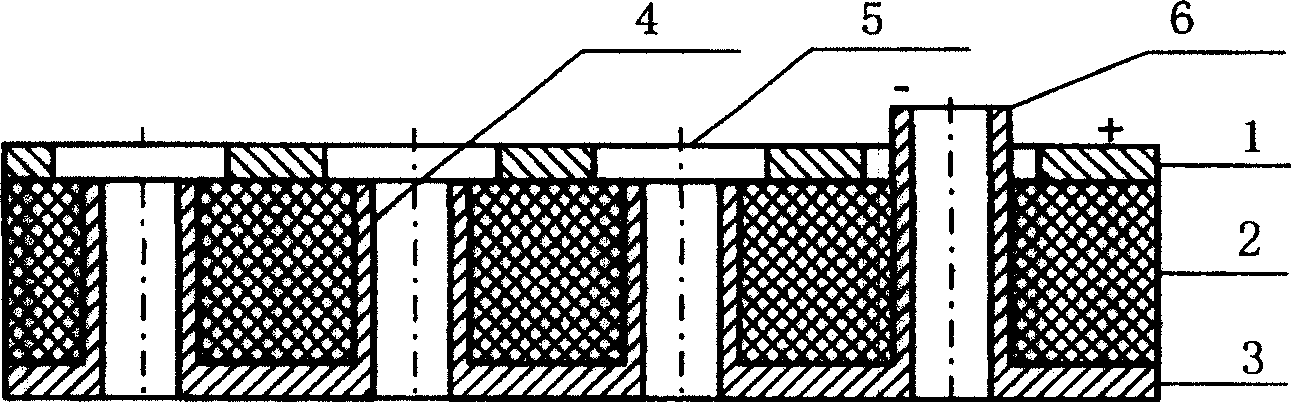

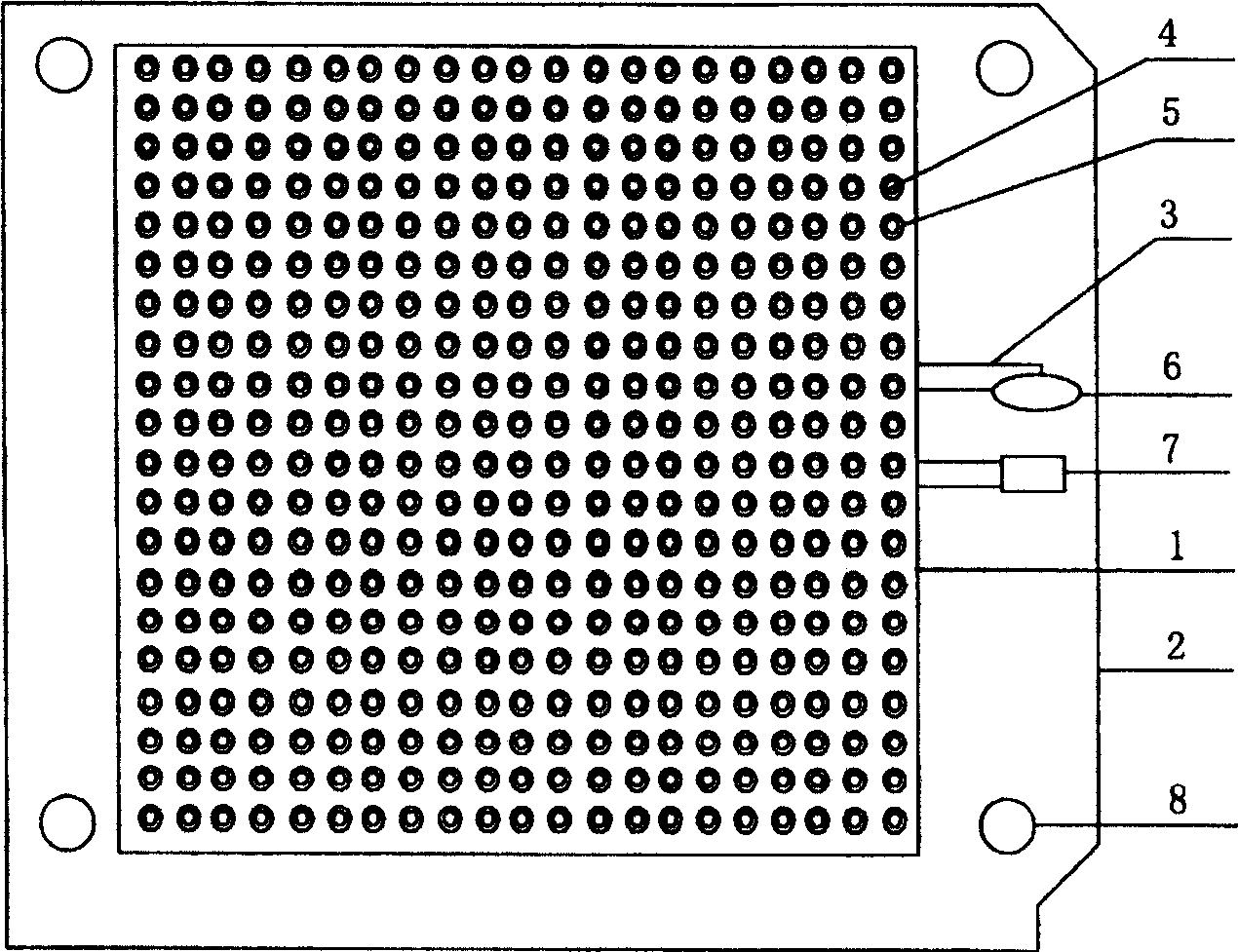

[0012] The following structural drawings further illustrate the specific implementation and working principle of the present invention.

[0013] figure 1 Schematic diagram of the structure of an embodiment of an array electrode type flat wall microcavity generating device provided by the present invention. The generating device is composed of a three-layer structure of the top layer 1, the middle layer 2 and the bottom layer 3. The top layer is a gold-plated copper layer , at the same time as the positive electrode of the power supply; the middle layer is an insulating layer, and polytetrafluoroethylene can be used as the insulating layer. The diameter range is 50-500 microns, the hole wall is coated with copper, and connected to the bottom layer; the bottom layer is a copper layer, which is used as the negative pole of the power supply.

[0014] The device mainly produces bubbles on the microporous cathode by electrolyzing water, and fills the micropores, thereby reducing th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com