Welding heat influenced ductility-excellent high yield ratio high tension steel plate

A steel plate quality technology, applied in the field of high yield ratio and high tension steel plate, can solve the problems of high thermal energy HAZ good toughness and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

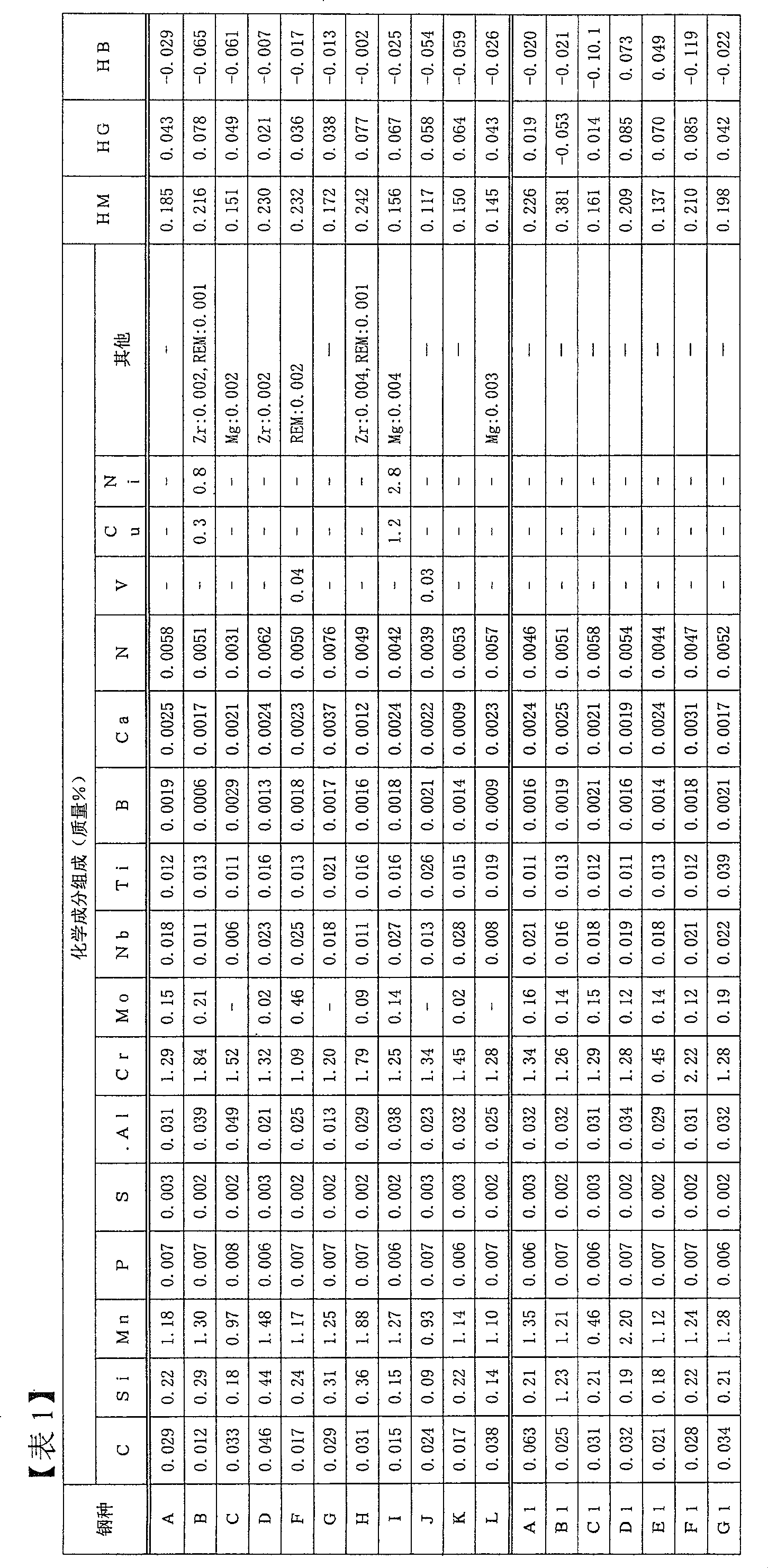

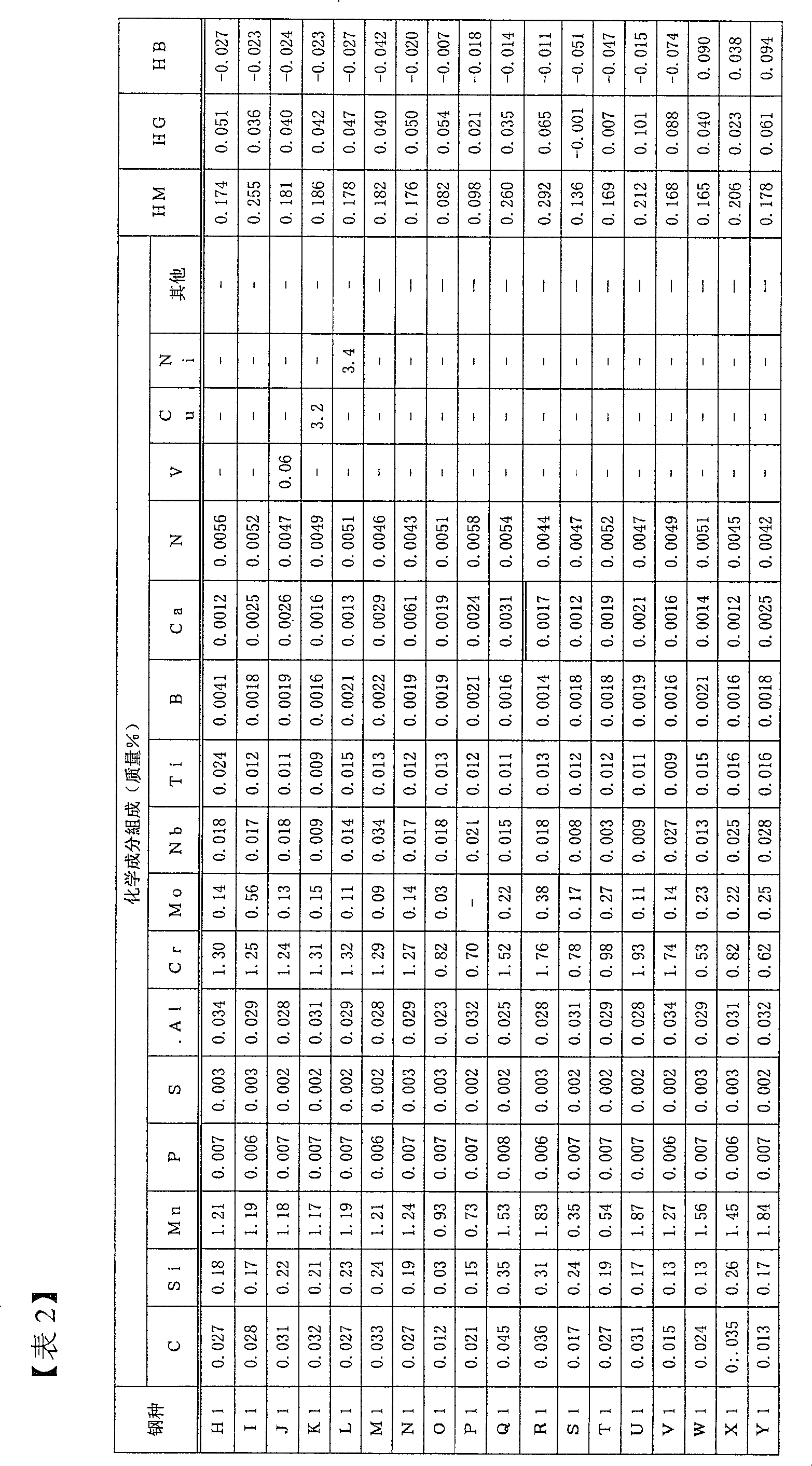

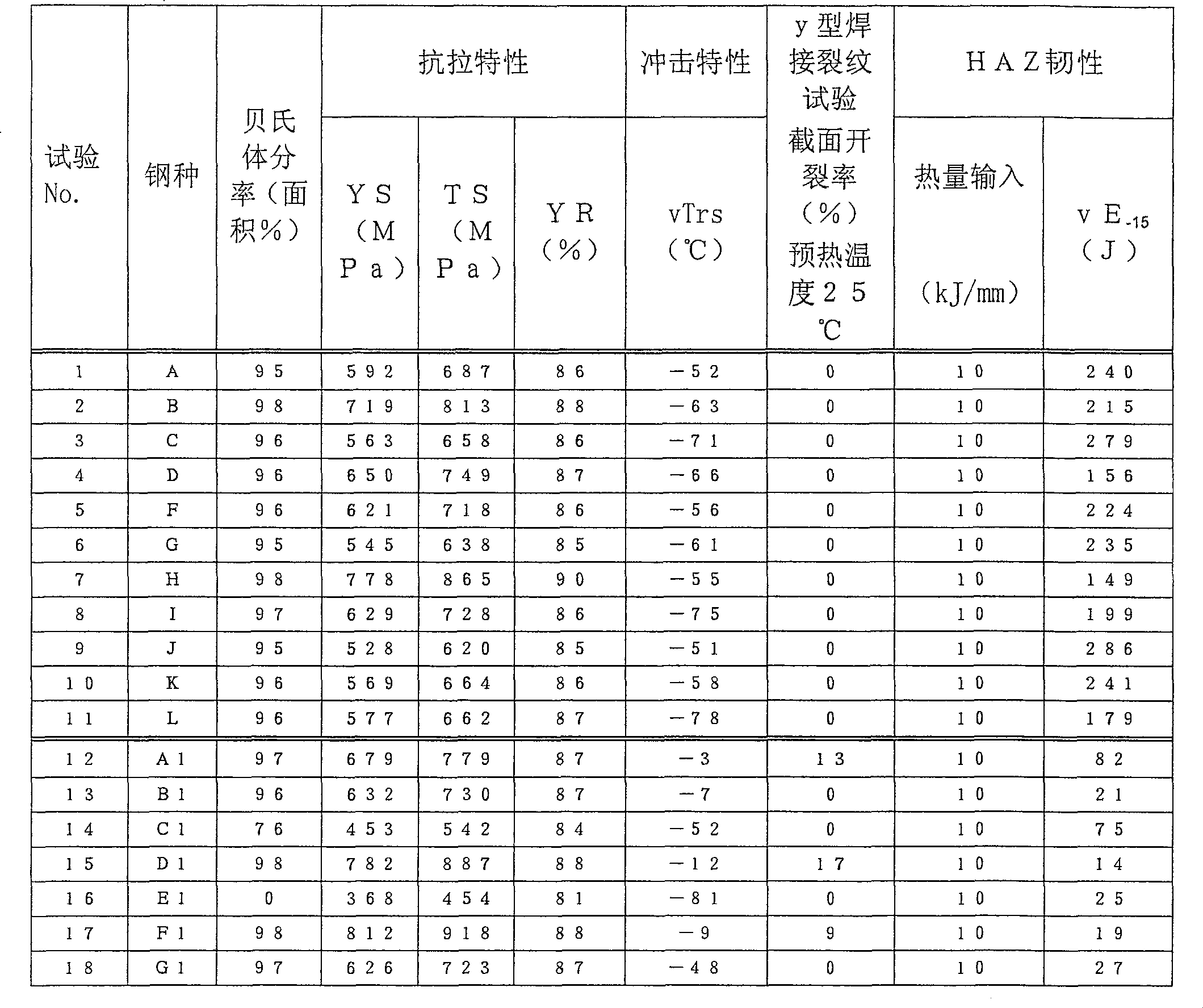

[0073] Steel sheets were manufactured under the production conditions shown in Tables 3 and 4 below using steels having the chemical composition shown in Tables 1 and 2 below. In addition, in Tables 1 and 2, the HM value, HG value, and HB value prescribed for the present invention are also shown.

[0074]

[0075]

[0076] 【table 3】

[0077] experiment

No.

steel type

Add before rolling

heat temperature

(℃) rolling finished

into temperature

(℃) cold after rolling

Cooling speed (℃

/ Second) plate thickness

(m

m) tempering temperature

(℃)

1 A 1100 800 15 50 — 2 B 1100 710 4 100 — 3 C 1100 800 13 50 — 4 D 1280 850 14 50 500 5 E 1200 800 15 50 — 6 F 1100 750 13 50 — 7 G 1100 800 3 100 650 8 H 1000 730 6 80 — 9 I 1100 880 52 20 — 10 J 1100 800 11 50 — 11 K 1050 900 air cooling 6 — 12 A1 1100 800 14...

Embodiment 2

[0110] Using steel type A shown in the above-mentioned Table 1, the HAZ reproduction test was carried out in the same manner as above except that the heat input was changed. At this time, the cooling time to reach 800-500° C. was changed so that the input heat amount corresponded to 1-20 KJ / mm, and a thermal cycle test was performed. Also, when the input heat is 1KJ / mm, the cooling time is 10 seconds; when the input heat is 2KJ / mm, the cooling time is 20 seconds; when the input heat is 5KJ / mm, the cooling time is 40 seconds; when the input heat is 7KJ / mm, the cooling time is 60 seconds, when the input heat is 15KJ / mm, the cooling time is 120 seconds, and when the input heat is 20KJ / mm, the cooling time is 160 seconds.

[0111] Thereafter, two pendulum impact test pieces (JIS Z 2202 V notch test pieces) were extracted from each test piece, and the average impact absorbed energy vE at -15°C was obtained for each steel plate. -15 There are 10 in total.

[0112] Table 7 below sh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com