Self binding film air checking packaging material J type bag and its manufacturing method

A technology of air packaging and manufacturing methods, applied to the types of packaging items, envelope/bag manufacturing machinery, packaging, etc., to achieve the effect of improving efficiency and convenience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The specific contents of the present invention will be described below with reference to the accompanying drawings.

[0043] 1. Utilizing the self-adhesive and adsorption properties of simple films, only four layers of plastic films are simply heat-sealed and bonded to produce non-return air packaging materials using self-adhesive films.

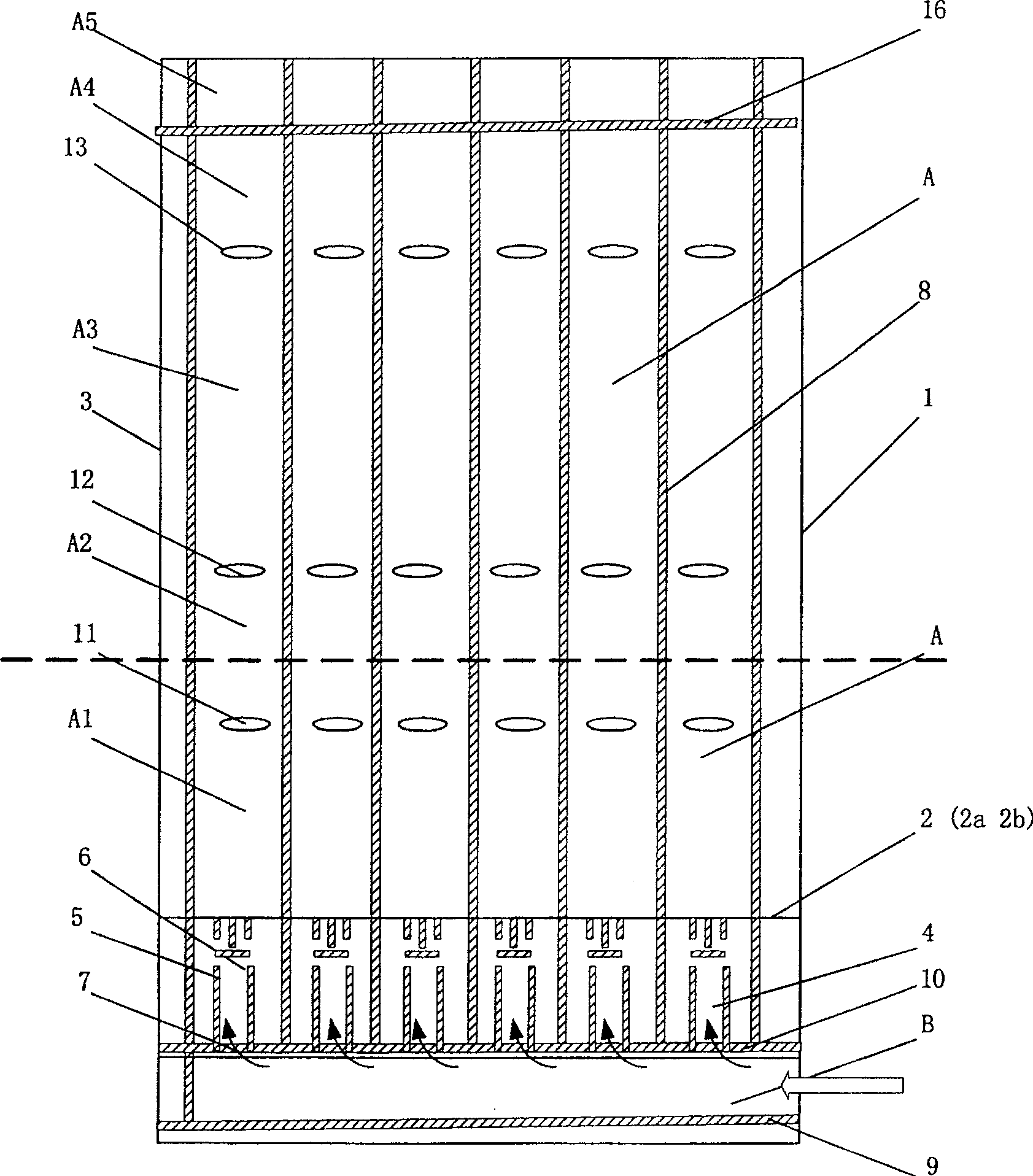

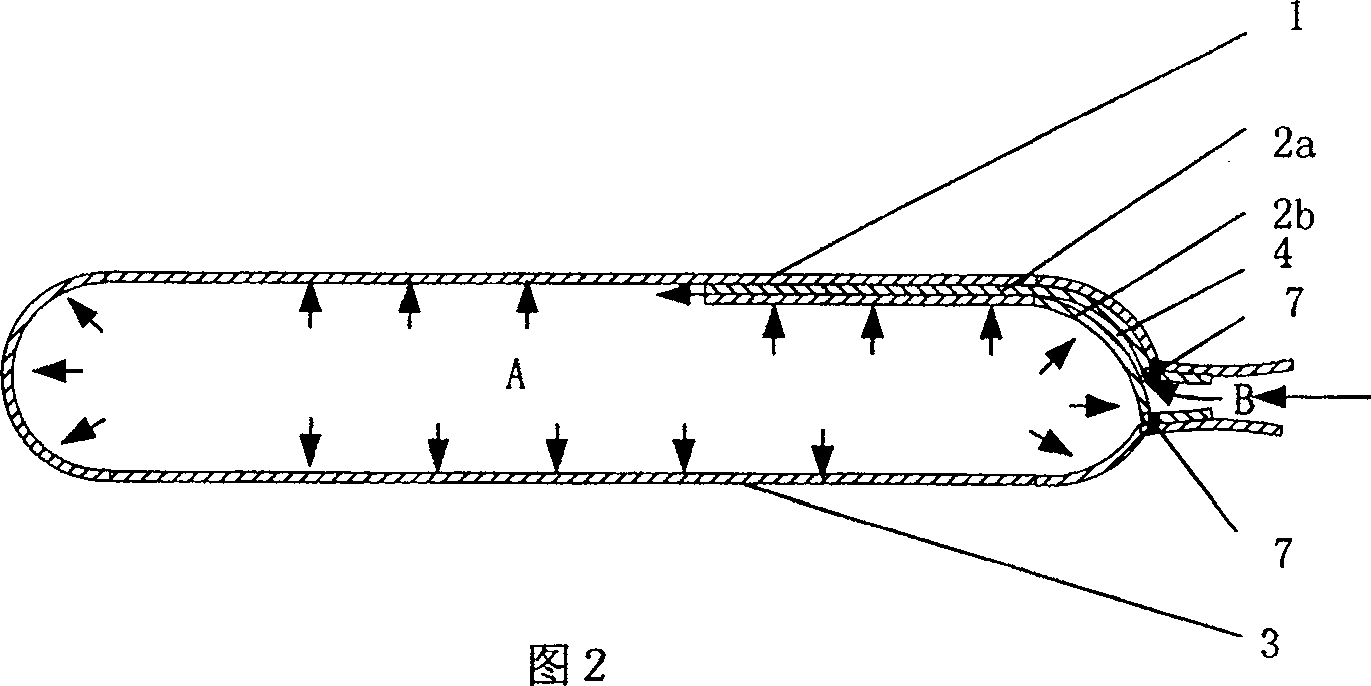

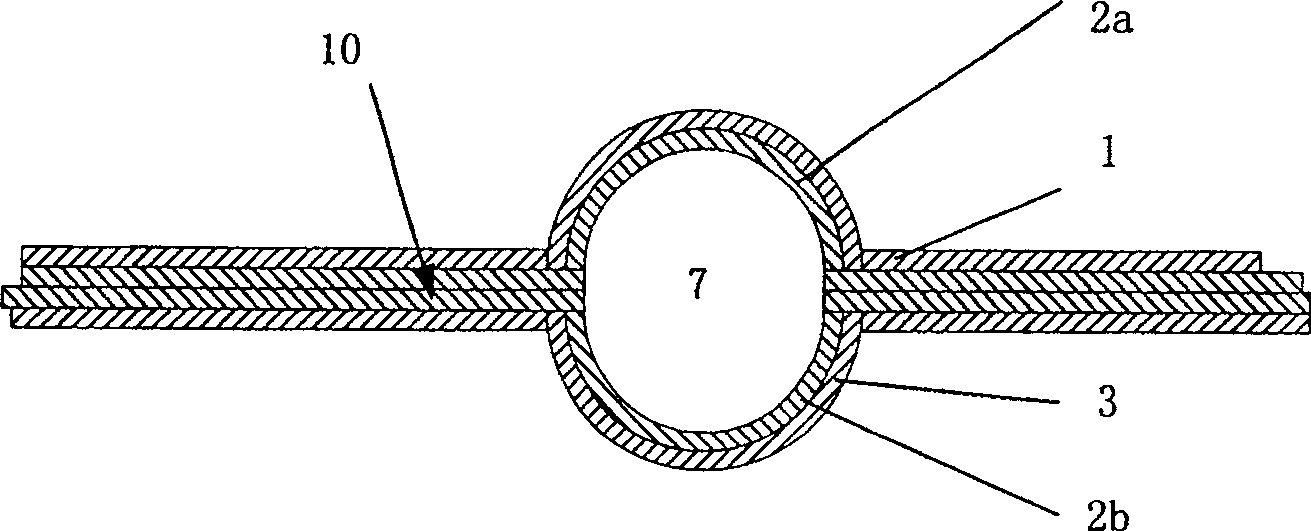

[0044] Such as figure 1 : Take two layers of wider polyethylene film (or other composite films), and two layers of narrower polyethylene film. Put plastic film 1, the wider polyethylene film of plastic film 3 on the upper and lower surface layers, plastic film 2a, and the narrower polyethylene film of plastic film 2b, place plastic film 1, the middle layer of plastic film 3, plastic film 2a, plastic The sides of the film 2b are heat-sealed 5 and 6 to form a channel 4, and the four sides are heat-sealed 8, 9, 10 and 16 to form a closed space A. As shown in Fig. 2 heat seal 5, the end of heat seal 6, heat seal 10 does not stick plasti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com