Automatic sheet feeding device in two side scanning device

An automatic paper feeding device and double-sided scanning technology, applied in image communication, electrical components, etc., can solve the problem of shortening the length of double-sided scanners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

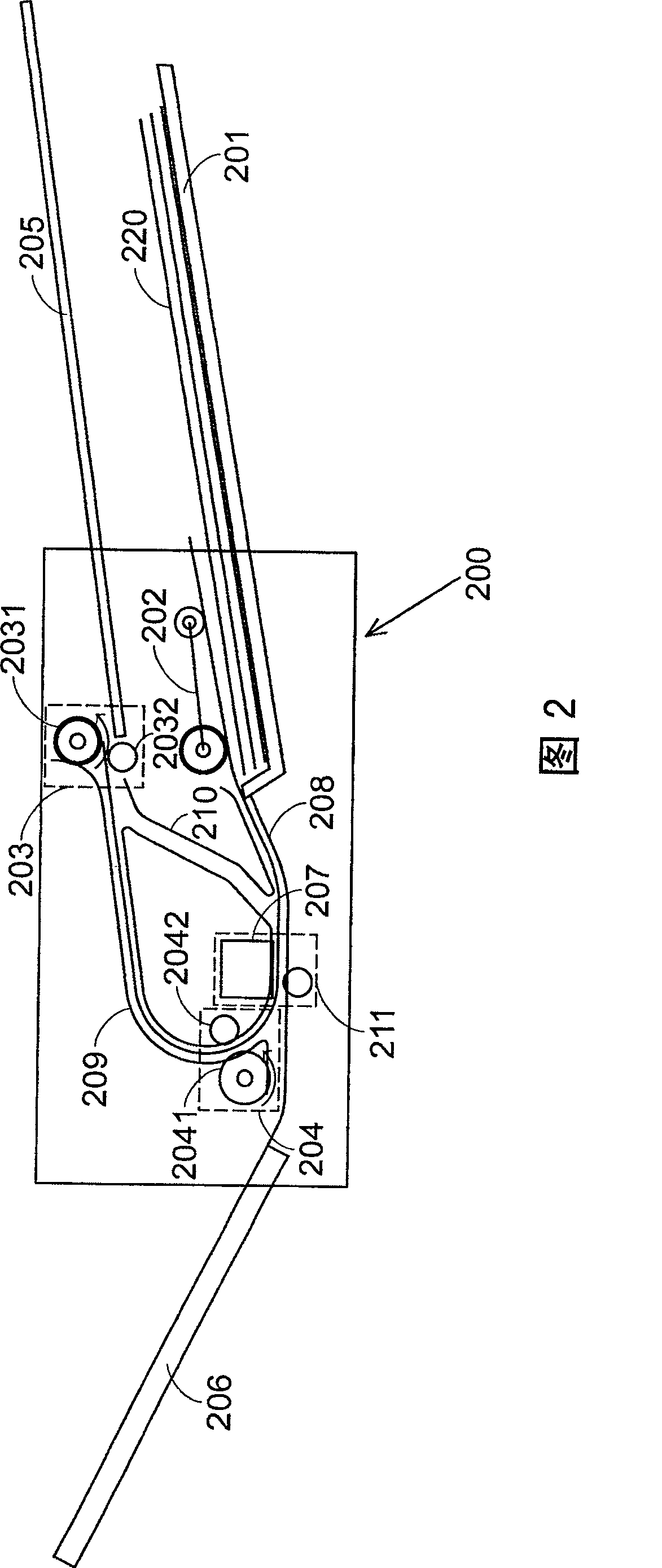

[0040] Please refer to FIG. 2 , which is a schematic diagram of a preferred embodiment of the present invention. In FIG. 2 , an automatic paper feeding device 200 with double-sided scanning function includes a paper input tray 201, a paper pickup roller set 202, a first paper output roller set 203, a second paper output roller set 204, a first paper output tray 205, The second paper output box 206, the scanning module 207, the first channel 208, the second channel 209 and the third channel 210, wherein the first paper output roller group 203 includes a first passive wheel 2031 and a first driving wheel 2032, and the second output The paper roller set 204 includes a second driven wheel 2041 and a second driving wheel 2042 .

[0041] Please refer to FIG. 2 , which is a schematic diagram of a preferred embodiment of the present invention for single-sided scanning. In FIG. 2 , when the automatic document feeder 200 performs single-sided scanning, the paper pick-up roller set 202 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com