Inserted copper-aluminum pipe resistance welder

A technology for resistance welding machines and copper-aluminum tubes, applied in the direction of resistance electrode holders, electrode features, tubular objects, etc., can solve problems such as unstable product quality, misproduction, waste of raw materials, etc., and achieve improved welding quality and equipment stability, The effect of improving the service life and reducing the cost of the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

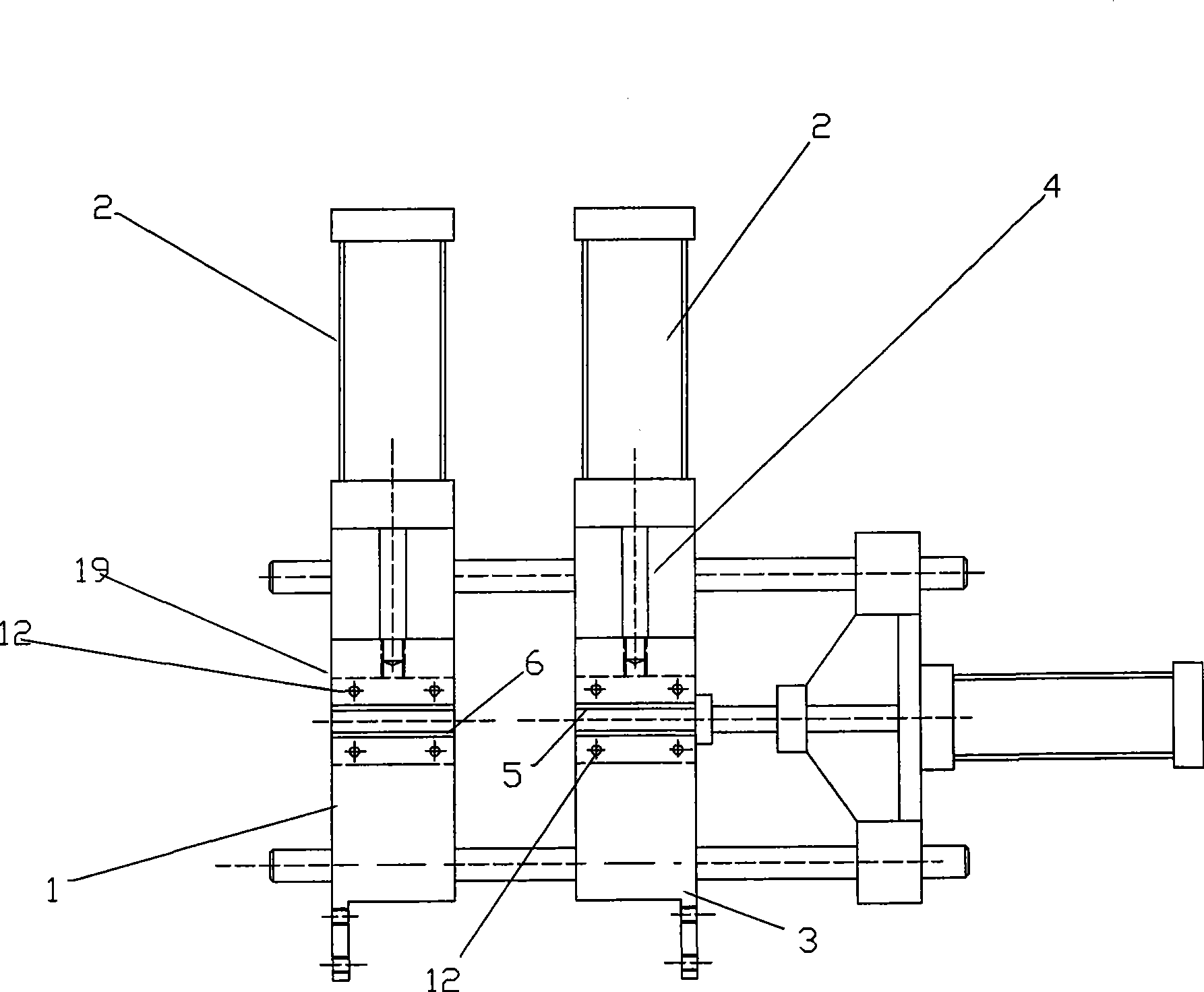

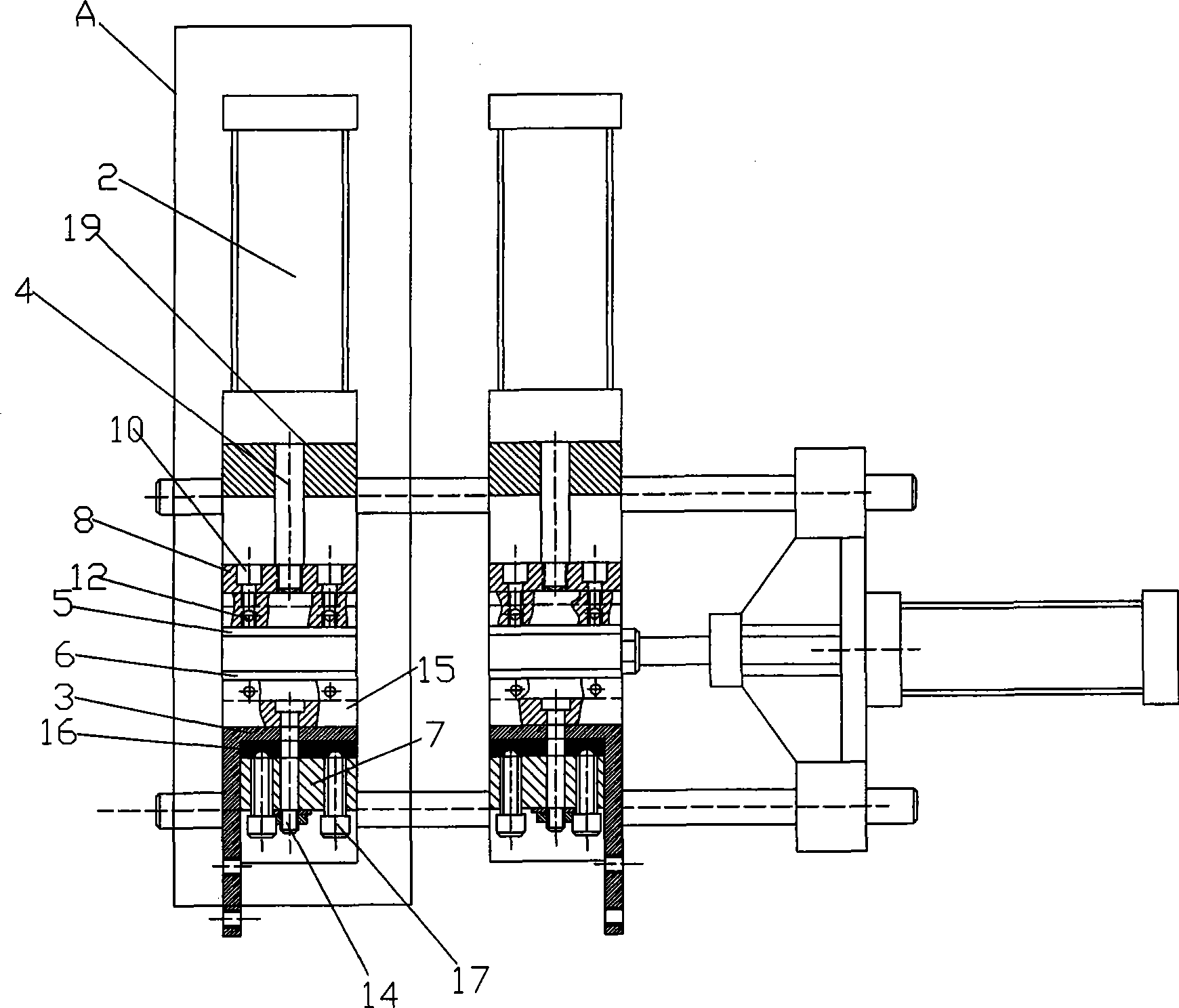

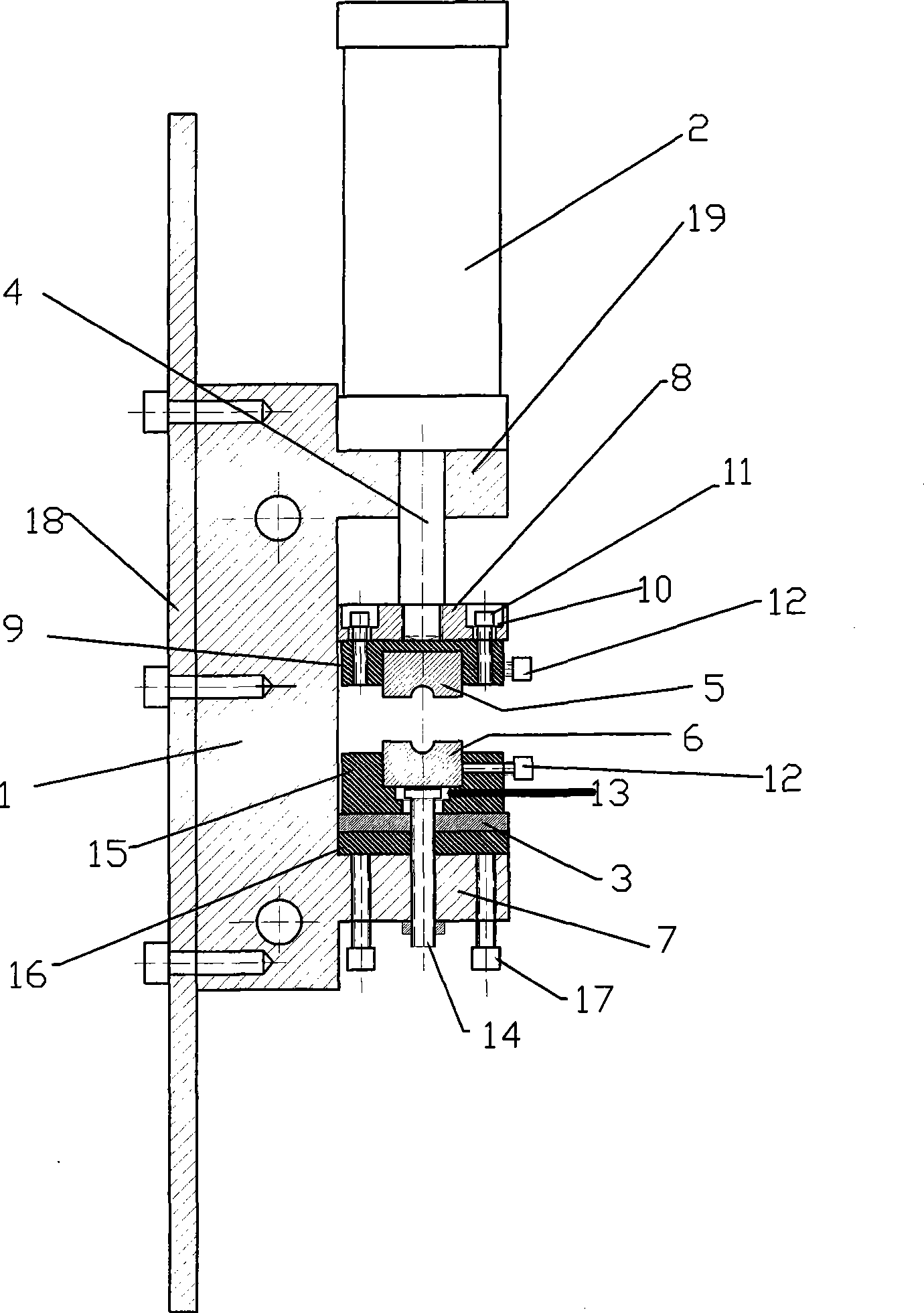

[0023] The present invention will be further described below in conjunction with accompanying drawing.

[0024] The plug-in type copper-aluminum tube resistance welding machine of the present invention comprises a machine head main body 1, a clamping cylinder 2, electrodes (5, 6), an output cable connector 3, and a clamping cylinder shaft 4, and the machine head main body 1 is fixed on the On the machine head fixing plate 18, an upper electrode adjustable fixing member is provided between the lower end of the clamping cylinder shaft 4 and the upper electrode 5, and a lower electrode can be arranged between the lower electrode 6 and the lower fixing block 7 of the machine head main body. Adjust the fixture; the clamping cylinder 2 is fixed on the clamping cylinder fixing block 19 of the machine head main body 1.

[0025] The above-mentioned upper electrode adjustable fixing part is composed of clamping cylinder shaft connecting part 8 and upper electrode fixing part 9 .

[002...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com