Vacuum contant pressure, mixer for internal combustion engine

An internal combustion engine and mixer technology, applied to internal combustion piston engines, combustion engines, engine components, etc., can solve problems such as unreasonable mixture concentration, difficulty in starting small-displacement motorcycles, and incomplete combustion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

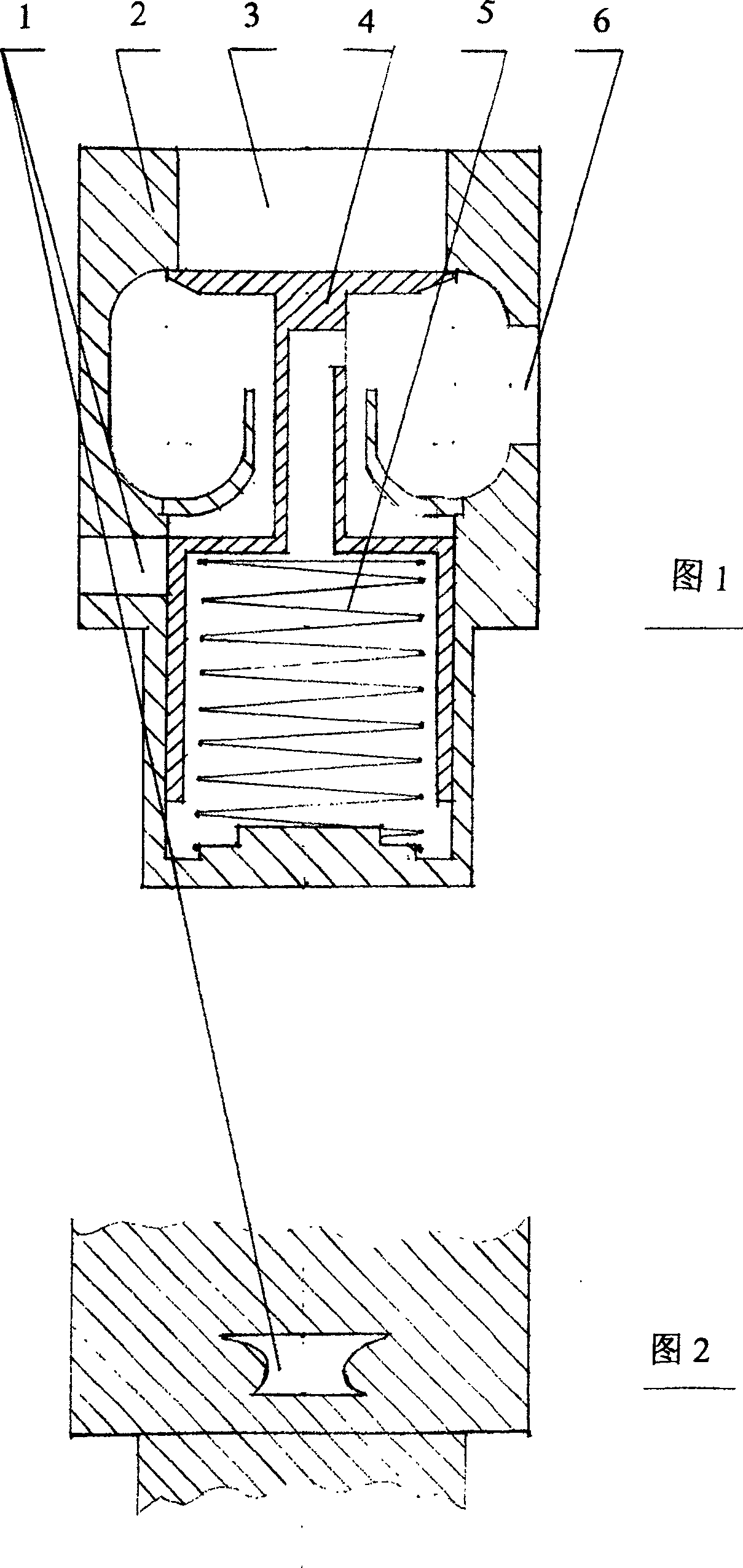

[0014] 1. For CNG / EFI dual-purpose fuel vehicles, the engine adopts a compression ratio of 12.5:1. When the gas is used, the spring force of the constant pressure spring 5 should be reduced as much as possible, and the maximum air intake of the engine cylinder should be increased to increase the gas power. The mixer Mixing function alone; when fuel is used, increase the elastic force of the constant pressure spring 5 to control the maximum cylinder air intake of the engine, so that the maximum compression force of the cylinder meets the anti-knock ability requirements of gasoline fuel, and avoid engine knocking. Constant pressure effect.

[0015] 2. Used in LPG single-fuel vehicles; (1) Prioritize filter power, adopt a compression ratio of 10:1, minimize the elastic force of constant pressure spring 5, and the mixer only plays the role of mixing air and gas; (2) Prioritize Filter fuel economy, adopt a compression ratio of 15:1, increase the spring force of the constant pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com