Supporting-point bearing equation for debugging and installing large automobile weighing apparatus

A technology for installation and commissioning and truck scales, applied in the field of law, can solve the problem of uneven force on the virtual and real support points of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

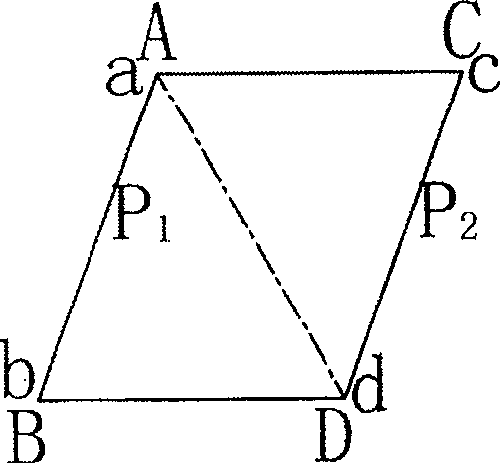

[0063] like figure 1 As shown, for the electronic truck scale weighing platform with four supporting points of the rigid body, that is, a weighing platform of one section, the diagonal (point a--point d) pad virtual method is adopted, including the following steps:

[0064] ① After the normal installation of large electronic truck scales, use non-standard weights for calibration,

[0065] ② From the weighing instrument of this large-scale electronic truck scale, the load-bearing values of each support point a, b, c, and d are called A, B, C, and D respectively, and the average point of two adjacent support points is calculated. Bearing value: P 1 =(A+B) / 2,P 2 =(C+D) / 2,

[0066] ③ A, B and P 1 To compare, C, D and P 2 Compare,

[0067] ④ The plan for padding is as follows: the padding height is lower than the support point of the average point load-bearing value, so that the point load-bearing value reaches the average point load-bearing value: if the load-bearing value...

Embodiment 2

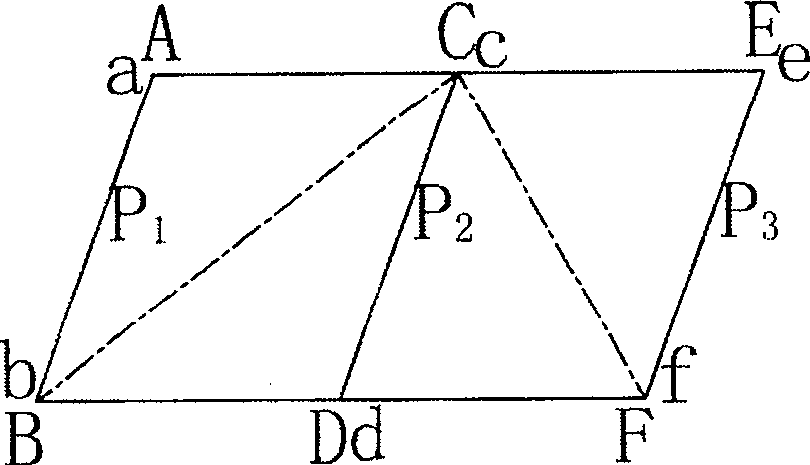

[0069] like figure 2 As shown, for the hinged six-support point electronic truck weighing platform, that is, the two-section weighing platform, a single V type (point b--point c--point f) or an angle type (point b--point c--e point) pad virtual method, comprising the following steps:

[0070] ① After the normal installation of large electronic truck scales, use non-standard weights for calibration,

[0071]② From the weighing instrument of this large-scale electronic truck scale, the load-bearing values of each support point a, b, c, d, e, f are called A, B, C, D, E, F respectively, and the corresponding Average load-bearing value of adjacent two support points: P 1 =(A+B) / 2,P 2 =(C+D) / 2,P 3 =(E+F) / 2,

[0072] ③ A, B and P 1 To compare, C, D and P 2 To compare, E, F and P 3 Compare,

[0073] ④ The plan for padding is: pad the fulcrum whose height is less than the average point load-bearing value, so that the point load-bearing value reaches the average point load-b...

Embodiment 3

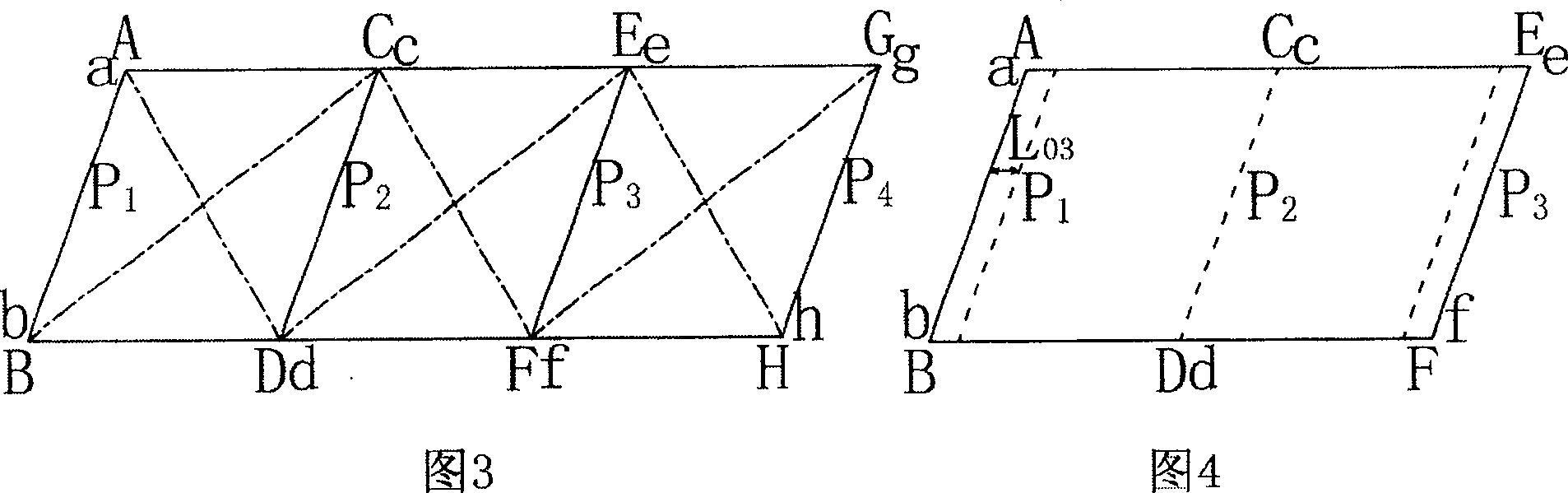

[0078] As shown in Figure 3, for the hinged eight-point electronic truck weighing platform, that is, the three-section conjoined weighing platform, double V-type (b point-c-point-f-point-g point) or Z-type (b-point- -d point--e point--g point) or trapezoid (b point-c point-e point-h point) or spoon type (a point-d point-e point-g point) The padding method includes the following steps:

[0079] ① After the normal installation of large electronic truck scales, use non-standard weights for calibration,

[0080] ② From the weighing instrument of this large-scale electronic truck scale, the load-bearing values of each supporting point a, b, c, d, e, f, g, and h are respectively A, B, C, D, E, and F , G, H, calculate the average point load-bearing value of two adjacent support points: P 1 =(A+B) / 2,P 2 =(C+D) / 2,P 3 =(E+F) / 2,P 4 =(G+H) / 2,

[0081] ③ A, B and P 1 To compare, C, D and P 2 To compare, E, F and P 3 To compare, G, H and P 4 Compare,

[0082] ④ The plan for pad...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com