Method for measuring concrete setting time based on strain time on-line measuring

A technology of solidification time and measurement method, applied in the field of civil engineering, can solve the problems of large differences in concrete solidification time and difficult online measurement of concrete

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

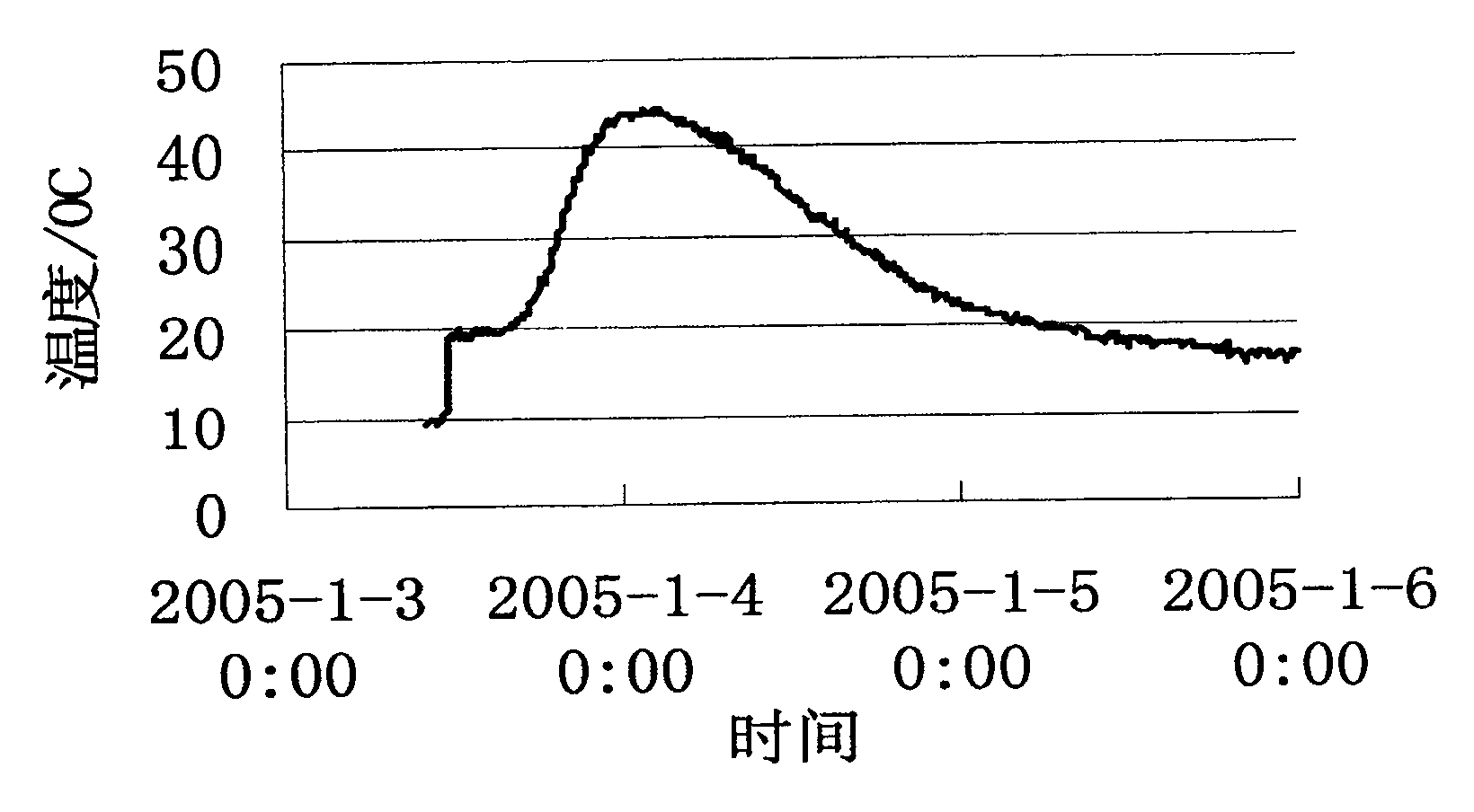

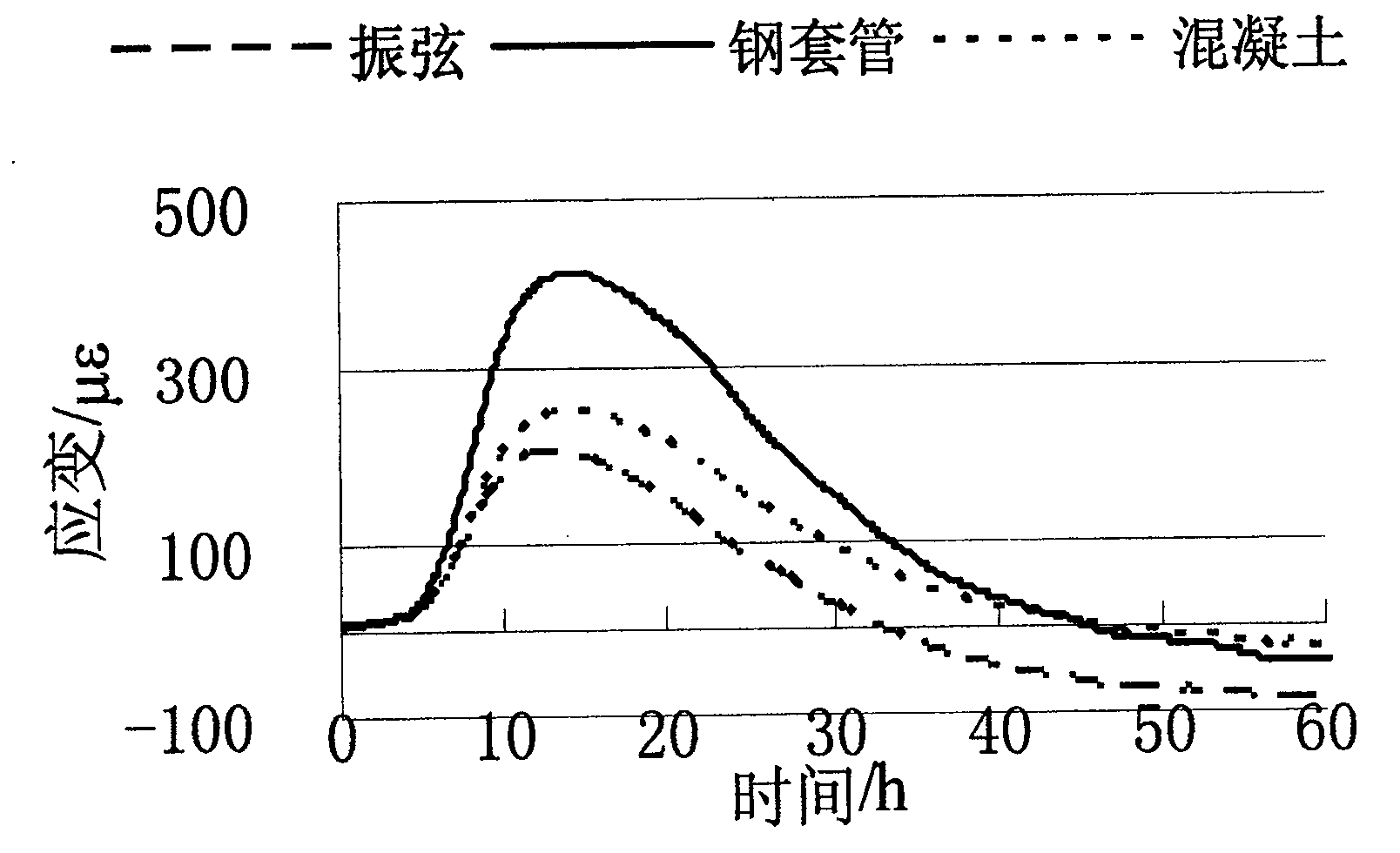

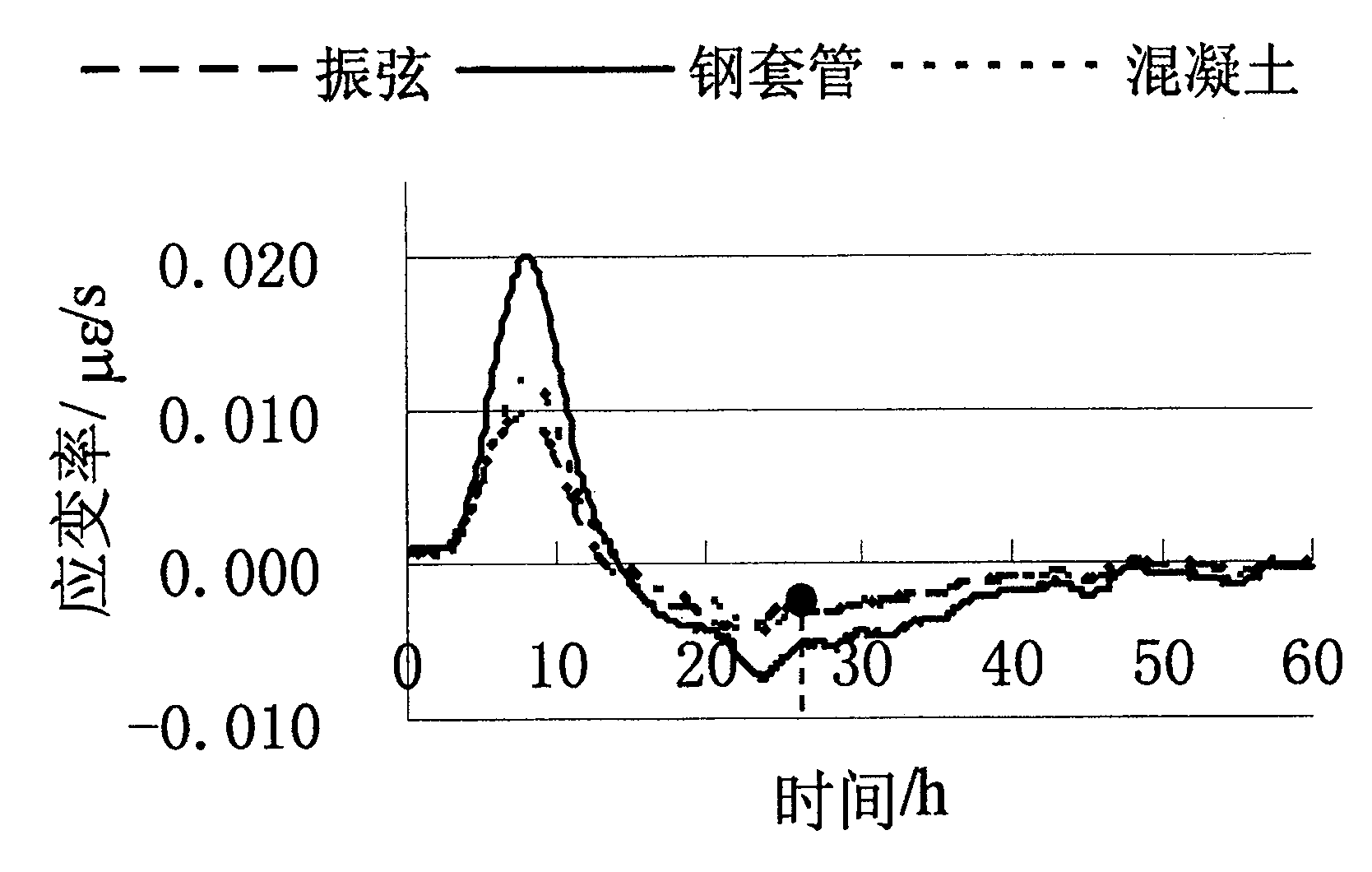

[0058] Embed JMZX-215AT embedded temperature strain gauges from Changsha Jinma High-Tech Co., Ltd. on the section numbered 2G of the Xijiang Bridge. The embedding position of the vibrating wire strain sensor and temperature sensor is 20cm deep from the concrete surface. The automatic data acquisition system also uses the company's JMZX-32 vibrating wire acquisition module, which can measure strain and temperature at the same time, and conduct online measurement of strain and temperature during the concrete solidification process, and the measurement time interval is 10 minutes / time. figure 1 It is a diagram of the temperature change during the concrete pouring process. As shown in the figure, it can be seen from the figure that the temperature measurement is reasonable. There is a jump in the temperature after the concrete is poured. This is because the initial temperature of the concrete is basically the water temperature, which is higher than the environment. Temperature (win...

Embodiment 2

[0060] For the measurement on the section numbered 3G of the Xijiang Bridge, the measurement method is the same as in Example 1. Measurement results such as Figure 4 It can be seen from this figure that the characteristics shown in Example 1——after a certain time, the strain rate measured sinusoidally and the thermal expansion strain of concrete do begin to overlap, and the setting time of concrete can be obtained from their overlapping starting point as 31.8 hours . Measuring equipment and process condition are with embodiment 1.

Embodiment 3

[0062] For the measurement on the section numbered 4G of the Xijiang Bridge, the measurement time interval is 30 minutes / time; other measurement methods are the same as in Embodiment 1. Measurement results such as Figure 5 Shown, measurement result has the same characteristics of embodiment 1; The solidification time of recording concrete is 29.2 hours. Measuring equipment and process condition are with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com