Emergency braking device for a lift cabin

A technology for emergency braking, elevator cars, used in transportation and packaging, elevators, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

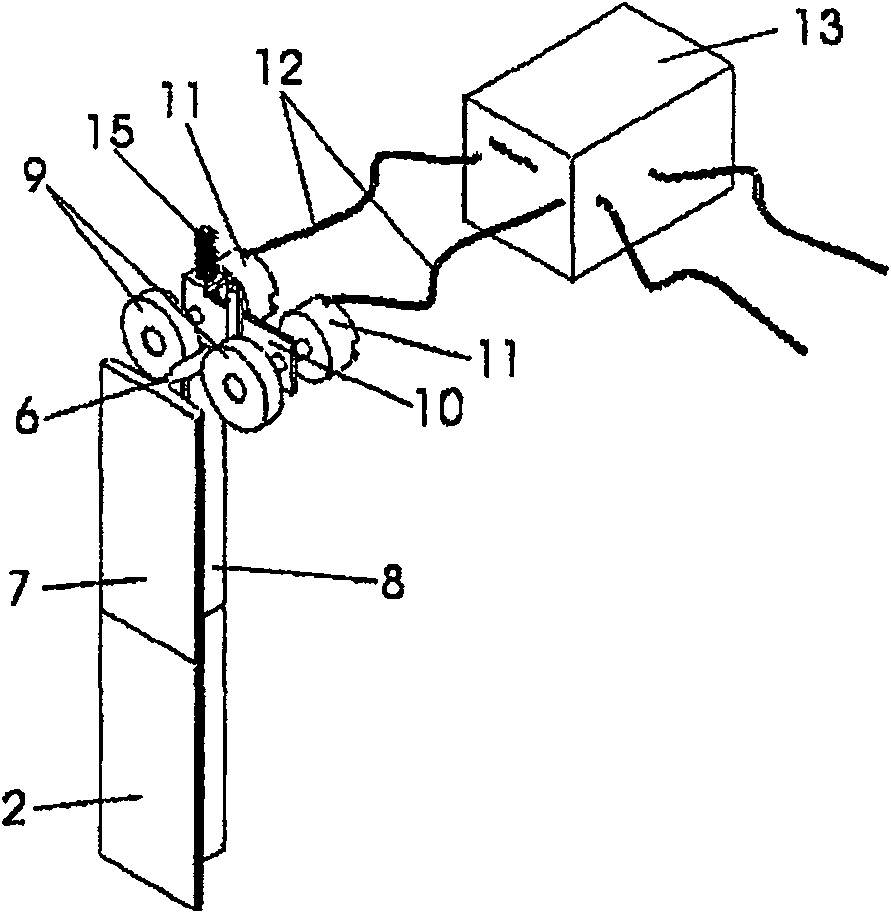

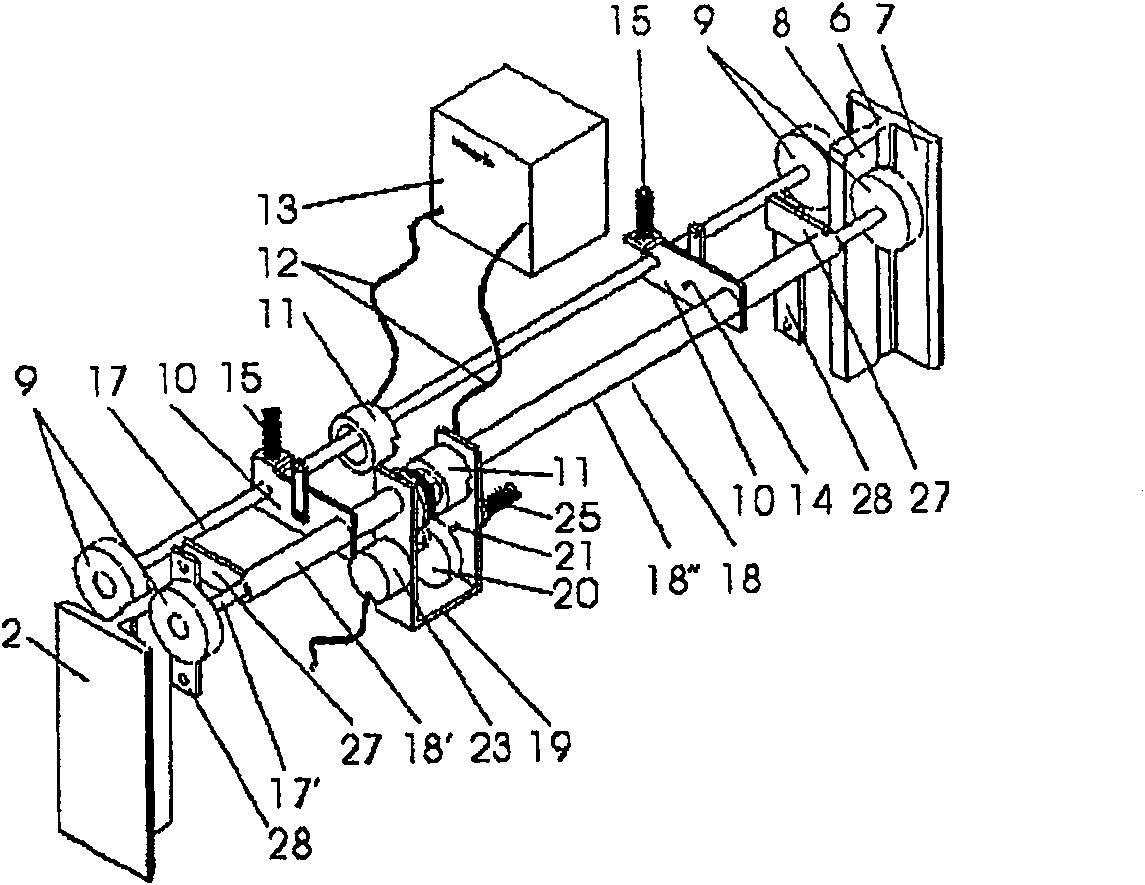

[0029] Such as figure 1 As shown, the guide rail 2 has a rail head 8 connected via a web 6 to a rail base 7 .

[0030] The wheels 9 rest against the sides of the rail head 8 and are held rotatably in the rocker 10 (see also figure 2 ) and is connected to the sensor 11 in a rotationally fixed manner. The sensor 11 is connected via a signal line 12 to a mechanism 13 for detecting excessive speed.

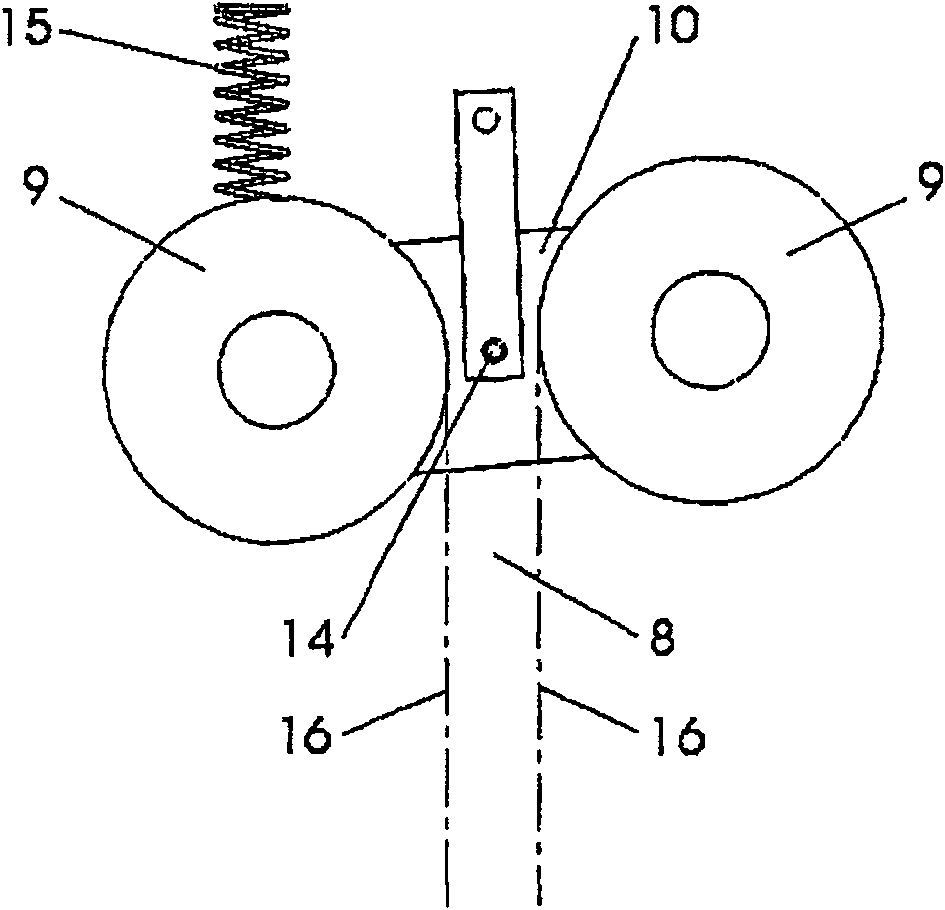

[0031] Such as figure 2 As shown, the swing link 10 is pivotally arranged between the two wheels 9 around the shaft 14 and bears the force of a spring 15, which is supported on a not shown support and is used to rotate the swing link 10, thereby turning the swing link 10 The wheels 9 press against both sides 16 of the rail head 8 . Since the net distance between the two wheels 9 is only slightly smaller than the width of the rail head 8 and the point of application of the spring 15 is far away from the axle 14 of the fork 10, a corresponding leverage is produced, even if the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com