Wig adhesive, wig utilizing the same and process for producing them

A manufacturing method and adhesive technology, applied in the direction of wigs, adhesives, adhesive types, etc., can solve the problems of wig base hardening and difficulty in matting, and achieve the effect of reducing thickness, reducing weight, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

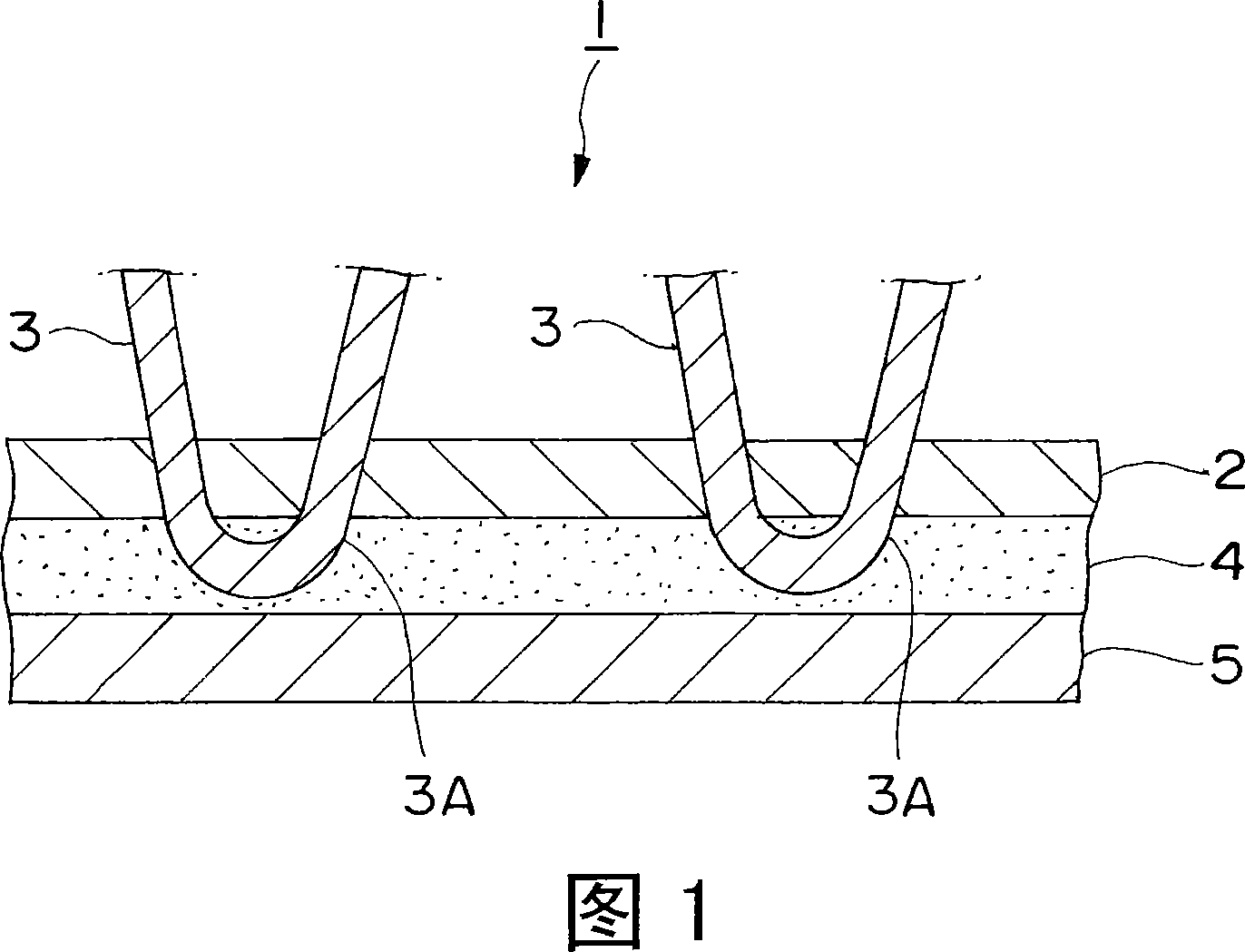

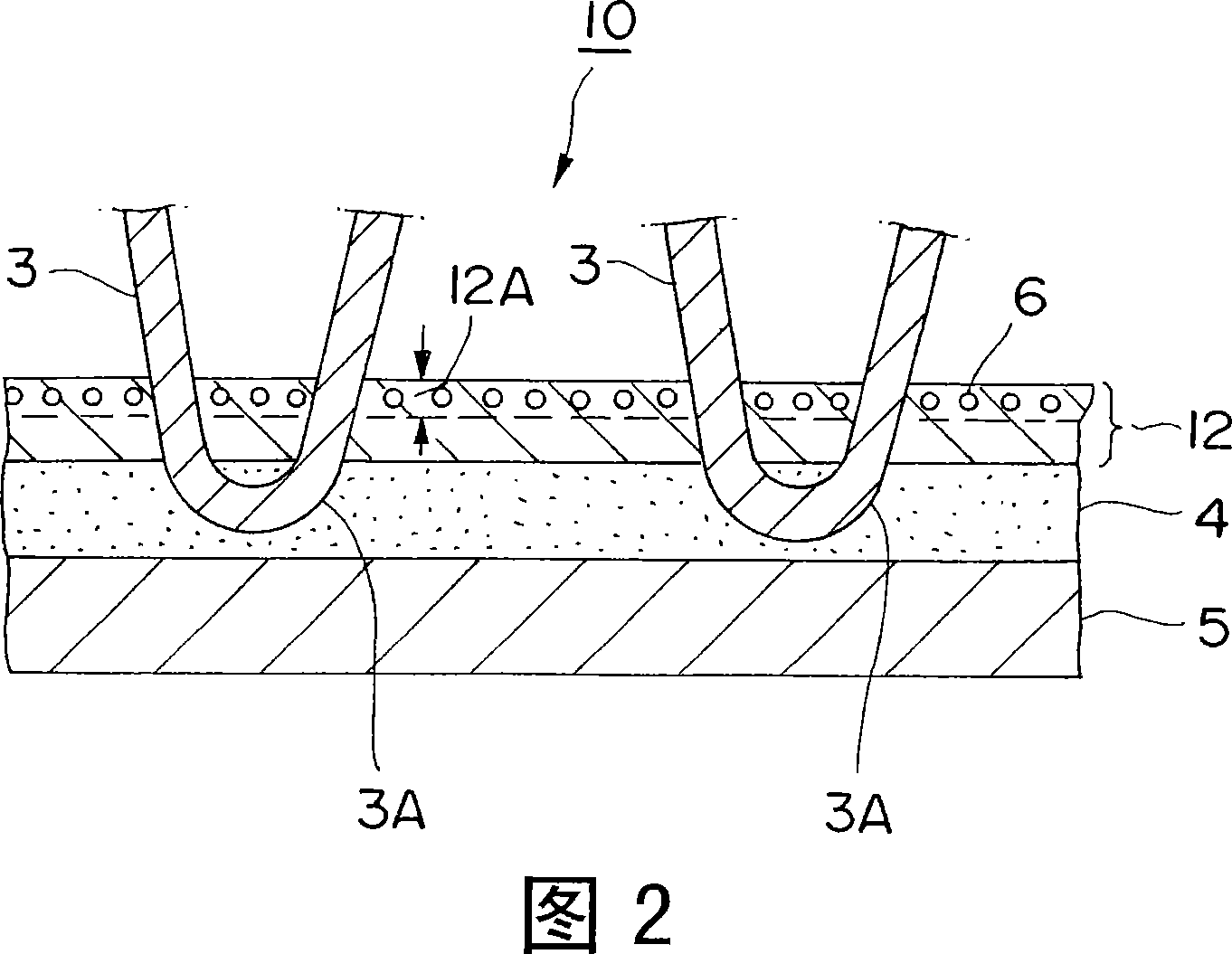

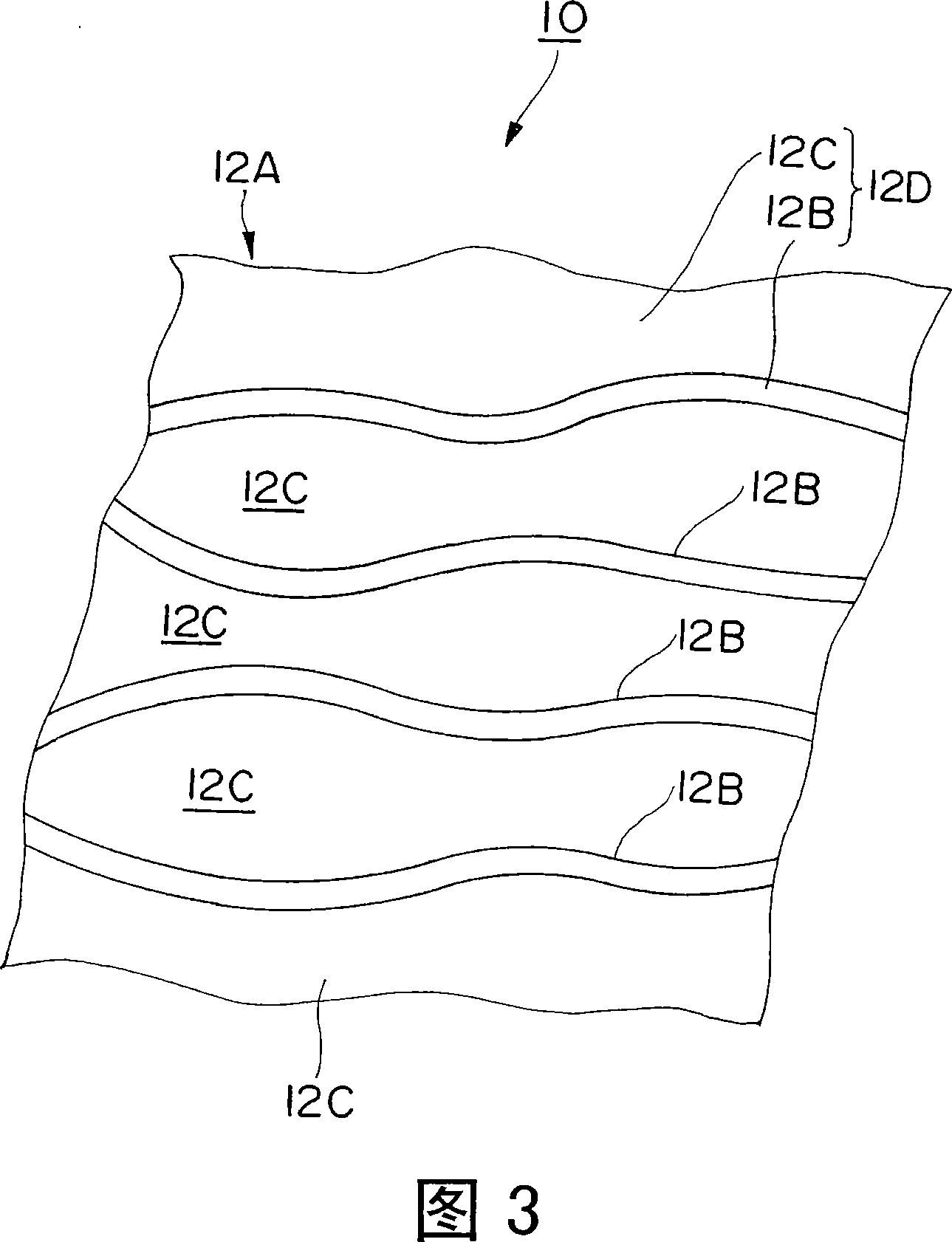

[0105] As an example, a wig 10 of the present invention having a matted hair base 12 was manufactured.

[0106] As the first step, a plaster mold prepared in advance in the shape of a wig wearer's head is coated with polyurethane elastomer dissolved in DMF (dimethylformamide) and MEK (methyl ethyl ketone) and an antifungal agent added. The solution was dried at a heating temperature of 60° C. for about 1 hour to produce a wig base 1 with a thickness of about 0.04 mm.

[0107] As the second step, the polyurethane elastomer was dissolved in DMF and MEK, and the antifungal agent was added to the solution, and further added powdered silica (average particle size: 3.1 μm to 4.1 μm) and ultraviolet light Absorbent, antioxidant, so as to make a solution for matting. The weight of silica is about 15% relative to the weight of polyurethane elastomer. This matting solution is applied to the wig base 1, and dried at a heating temperature of 60° C. for about 2 to 4 hours.

[0108] Next...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com