LED heat conducting seat and manufacture procedure thereof

A technology of LED lamps and heat pipes, applied in lighting and heating equipment, semiconductor devices of light-emitting elements, cooling/heating devices of lighting devices, etc., can solve the problems of difficult installation, low heat conduction efficiency, etc. The effect of high rate and simple processing procedure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

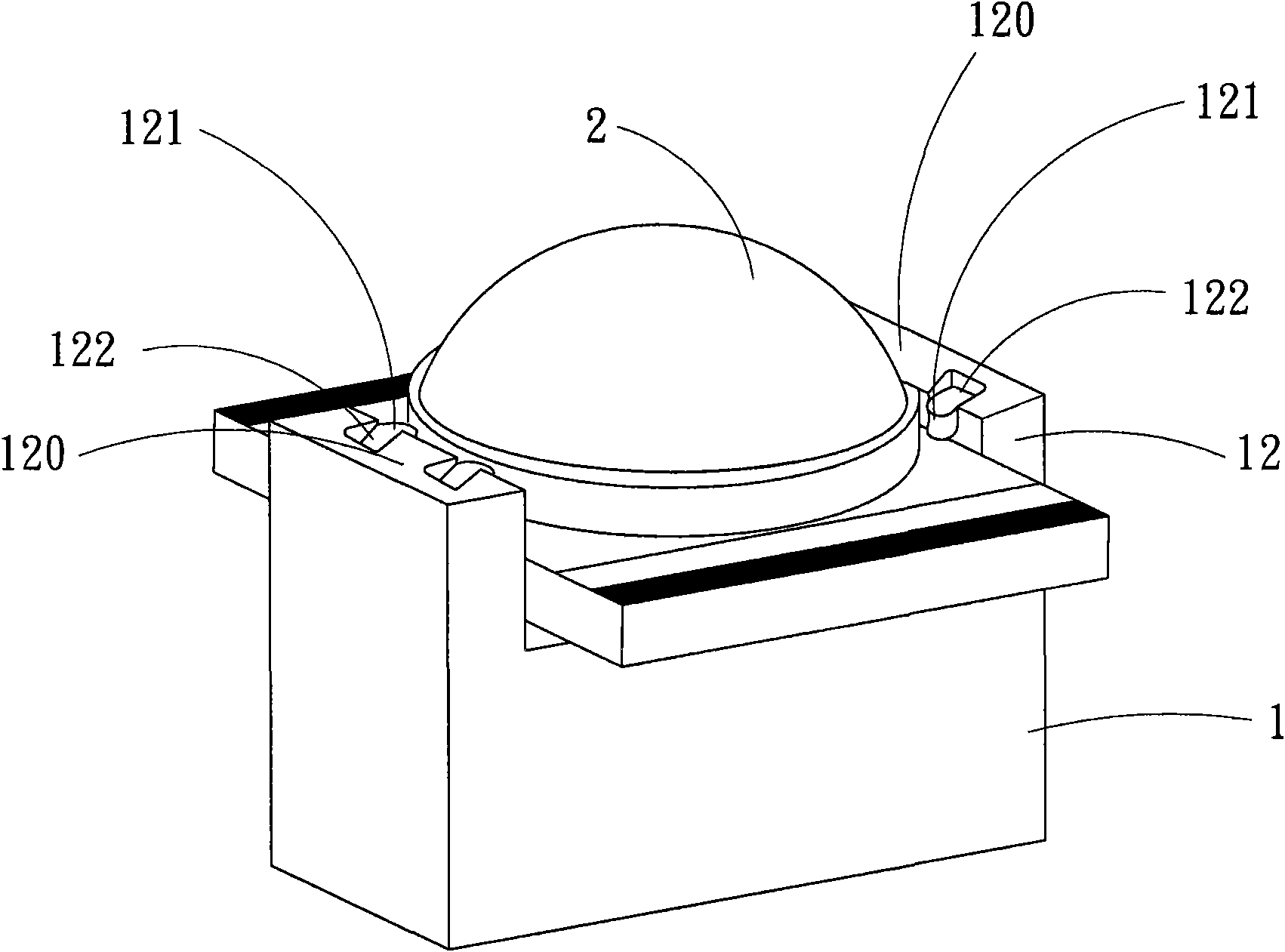

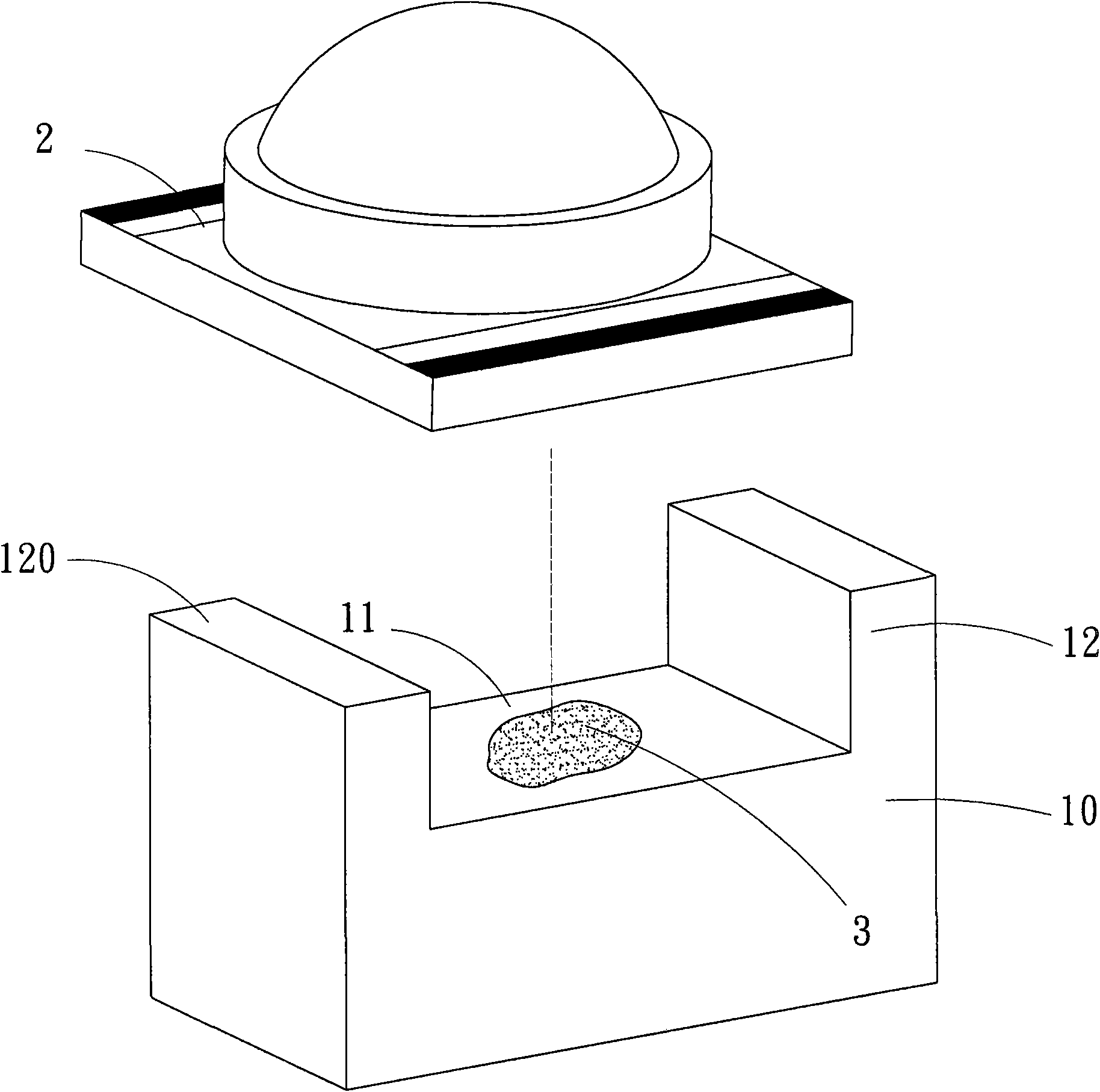

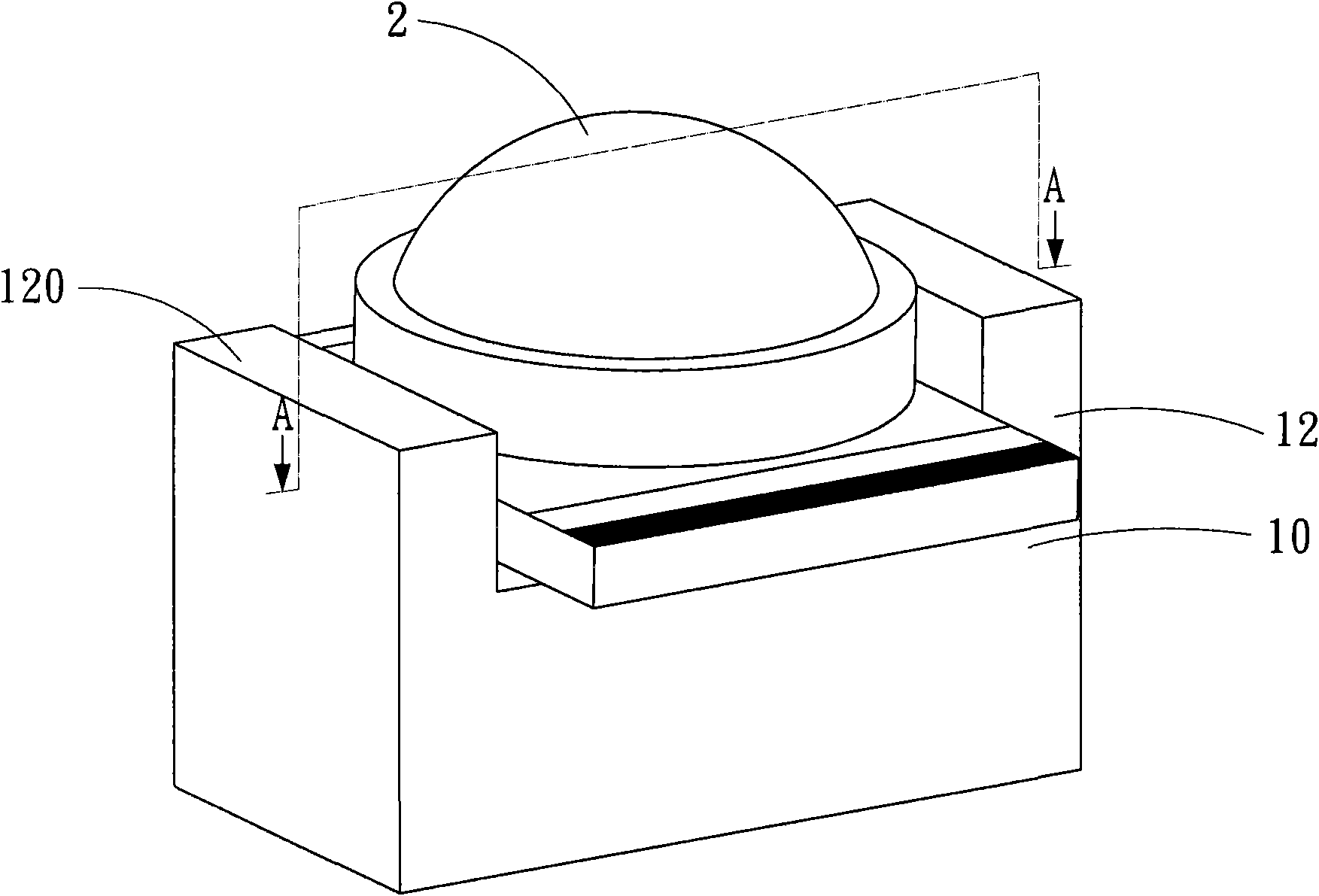

[0027] refer to figure 1 and figure 2 As shown, a kind of LED heat conduction seat 1 is to place the LED lamp 2 on the heat conduction seat prototype 10 (such as figure 2 As shown), the heat transfer seat 1 is provided with a placement area 11, and one or more fixing parts 12 are in the form of blocks or cylinders and are arranged on the periphery of the placement area 11 and are higher than the placement area 11. , the side of the fixing portion close to the placement area 11 is provided with a hooking portion 121 , and the hooking portion 121 faces the placement area 11 and buckles downward.

[0028] refer to Figure 2 to Figure 6 As shown, the placement area 11 of the LED heat transfer seat 1 of the present invention is used to carry the LED lamp 2, the LED lamp 2 is prevented from sliding through the fixing part 12 around the placement area 11, and the placement area 11 near the fixing part 12 One side of the LED lamp 2 is provided with a buckle 121 to buckle down the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com