Pull-fork assembly of vehicle

A technology for shifting fork assemblies and vehicles, applied to components with teeth, controlled components, transmission parts, etc., can solve problems such as uneven force, damage, loosening, etc., to improve loosening and relieve many troubles Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

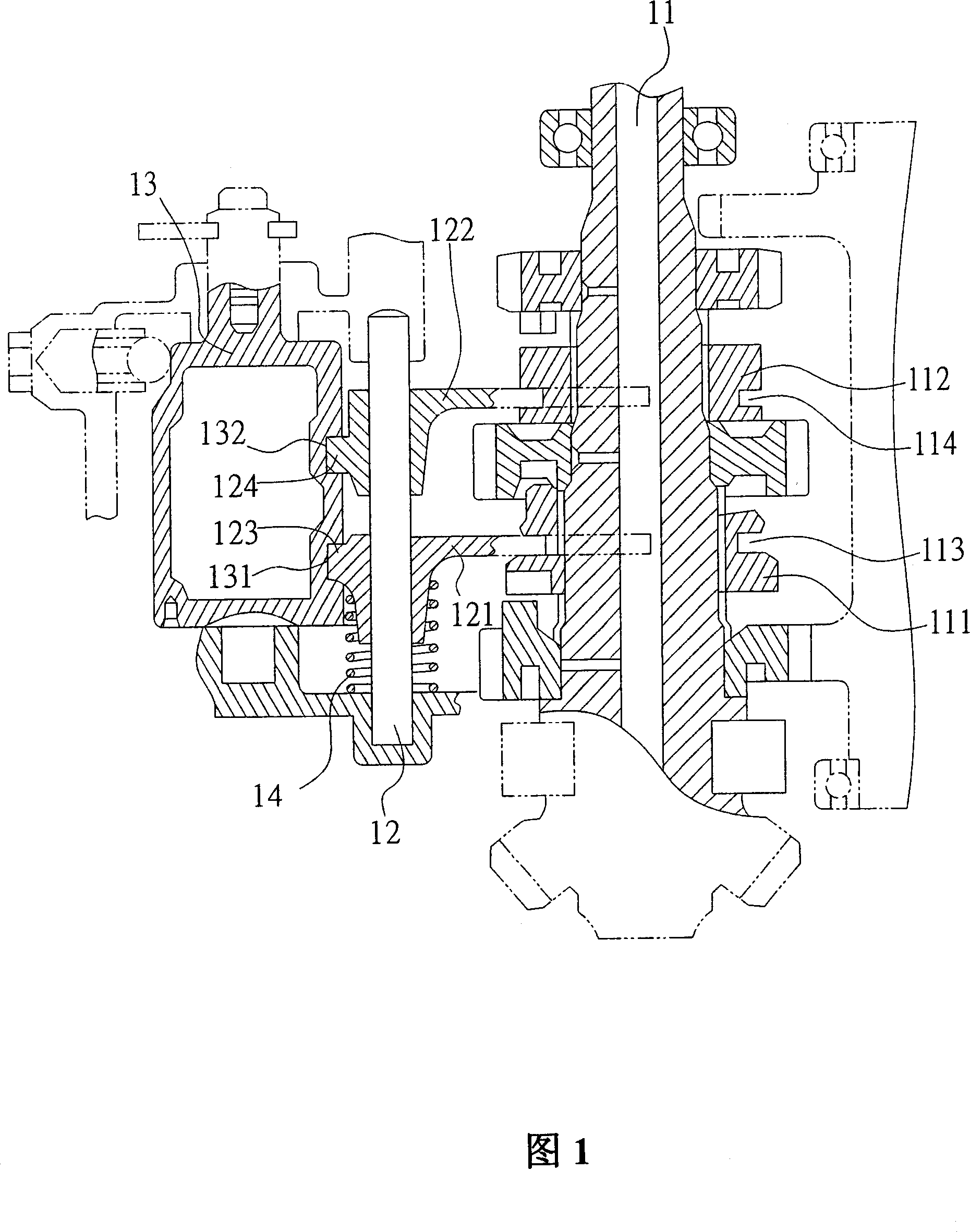

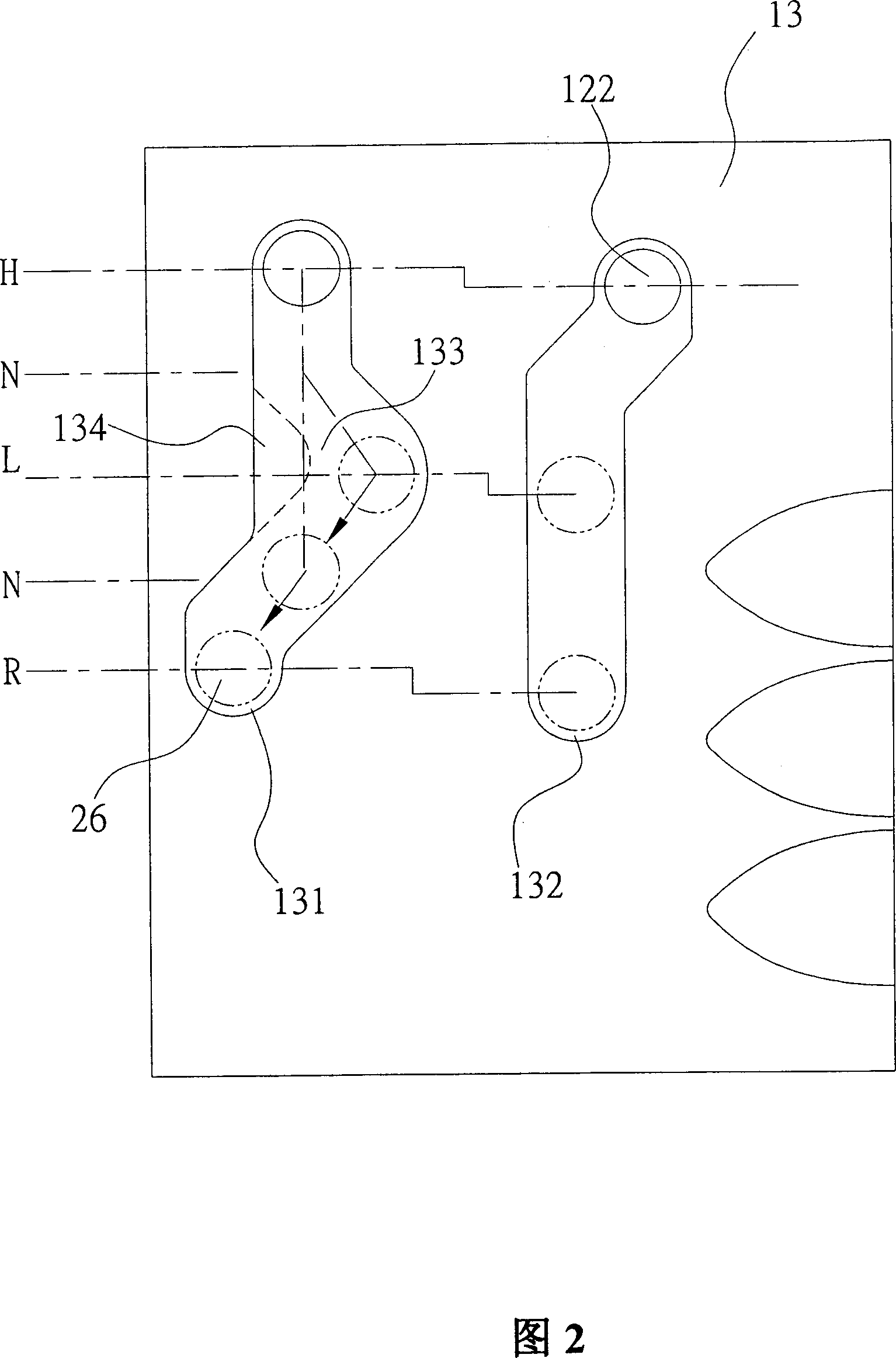

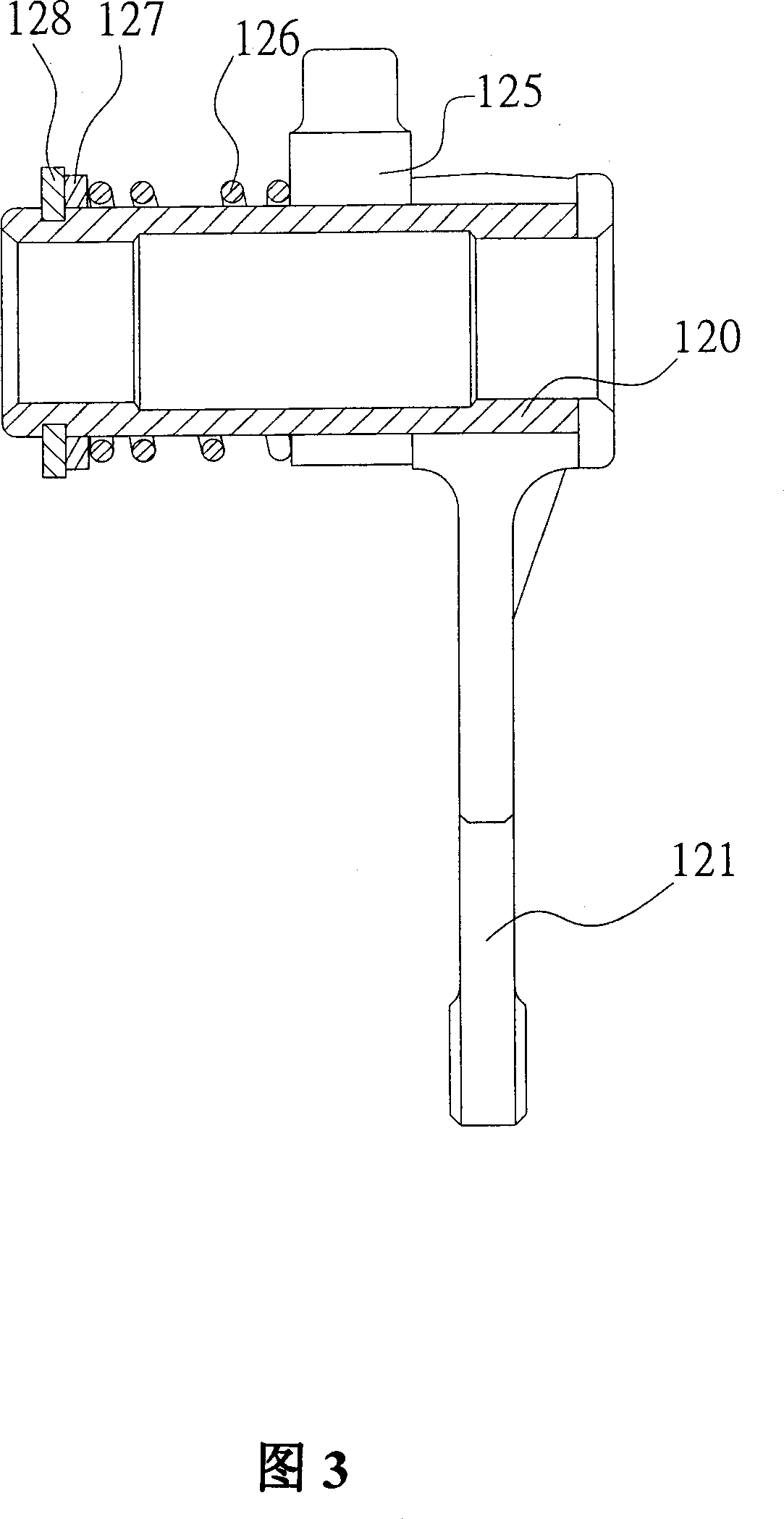

[0022] In order to further understand and understand the purpose of the present invention, technical features and effects thereof, the embodiments are given in conjunction with the accompanying drawings, and the detailed description is as follows:

[0023] In the gearbox 2 (as shown in Figure 6), be provided with a speed change hub 21, a shift fork shaft rod 22, a main shaft 23, a linkage shaft 24 and a driven shaft 25 in sequence, wherein on the speed change hub 21 is A receiving groove 211 and another receiving groove 212 are arranged in sequence, and a shifting fork assembly 221 and another shifting fork assembly 223 are sequentially arranged on the shifting fork shaft rod 22. One end of the transmission hub 21 can be accommodated in the accommodation groove 211 and the other accommodation groove 212 respectively. On the main shaft 23, a gear 231, a booster gear 232, a forward gear 233 and a gear 233 are arranged in sequence. The first slider 234, the shift fork assembly 22...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com