Centrifugal guide vane

A guide vane and blade technology, applied in the direction of the swirl axis can be reversed, the swirl device, etc., can solve the problems of large resistance loss, high amount of fine dust in the air, and inability to separate fine dust particles, etc. The effect of ensuring the urgency of the end, increasing the entry area, and prolonging the time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable the examiners of the patent office, especially the public, to further understand the essence and beneficial effects of the present invention, the applicant describes in detail the following specific examples, but the examples cannot be regarded as constituting limitations to the structure of the present invention.

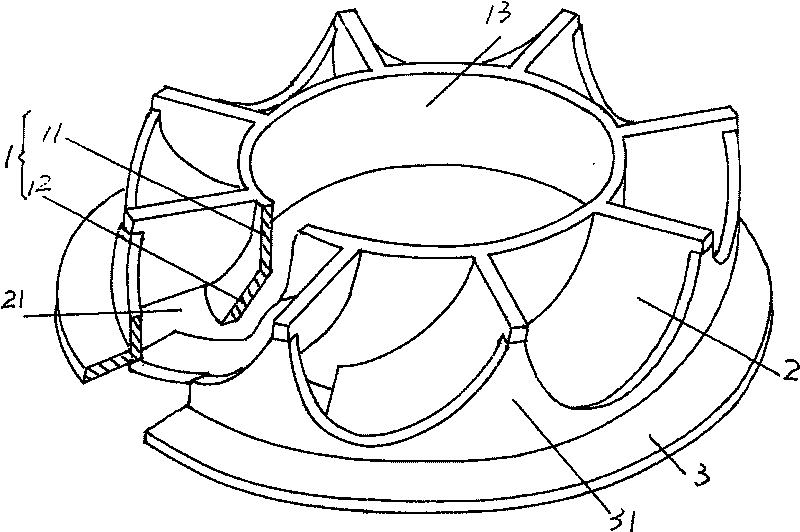

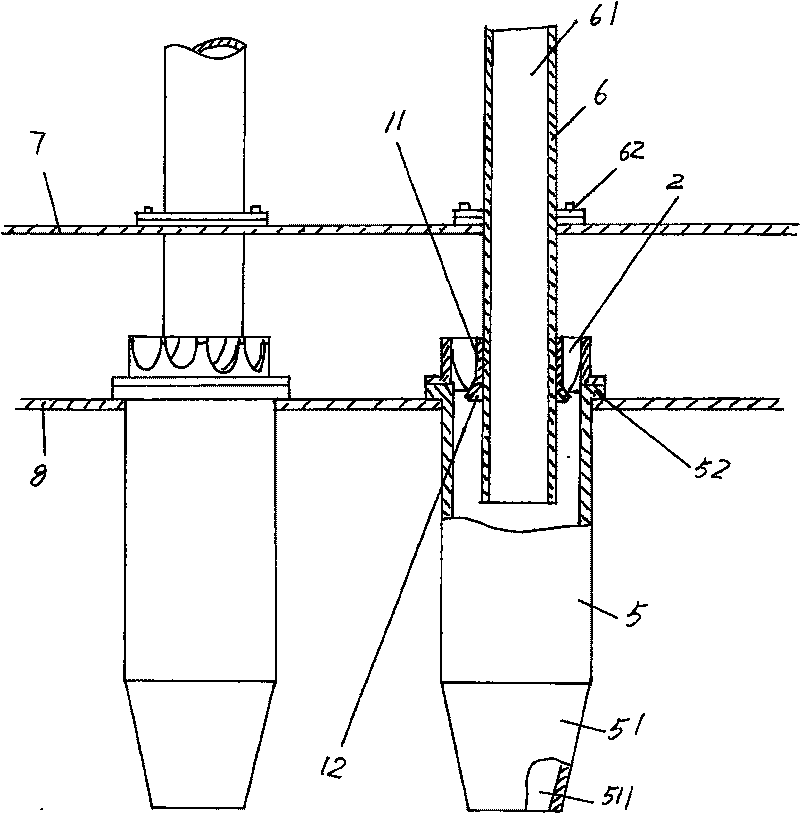

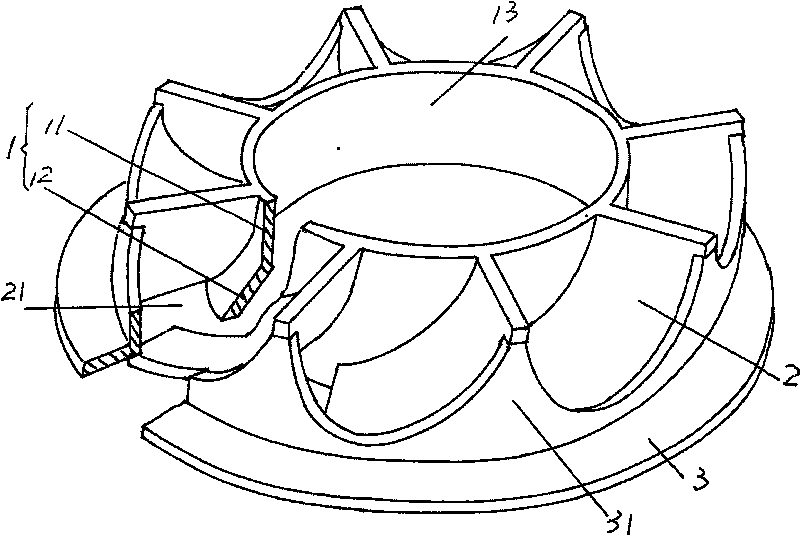

[0016] see figure 1 , as the body 1 of the centrifugal guide vane, the upper part is designed as a straight cylinder 11, and the lower part forms an outwardly expanded horn body 12, and the outer wall of the body 1 is formed as a paraboloid by the straight cylinder 11 and the horn body 12. It also helps to improve (change) the entry angle or cutting angle of the dusty air entering the cyclone cylinder. Between the outer wall of the main body 1, that is, the outer wall formed by the straight pipe body 11 and the trumpet body 12, a group of blades 2 with a shape tending to be tile-shaped is arranged. The recommended number of blades in this ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com