Clamping device

A clamping device and clamping arm technology, applied in workpiece clamping devices, metal processing, manufacturing tools, etc., can solve the problems of low lens yield and lens damage, and achieve the goal of avoiding lens damage and ensuring lens yield. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

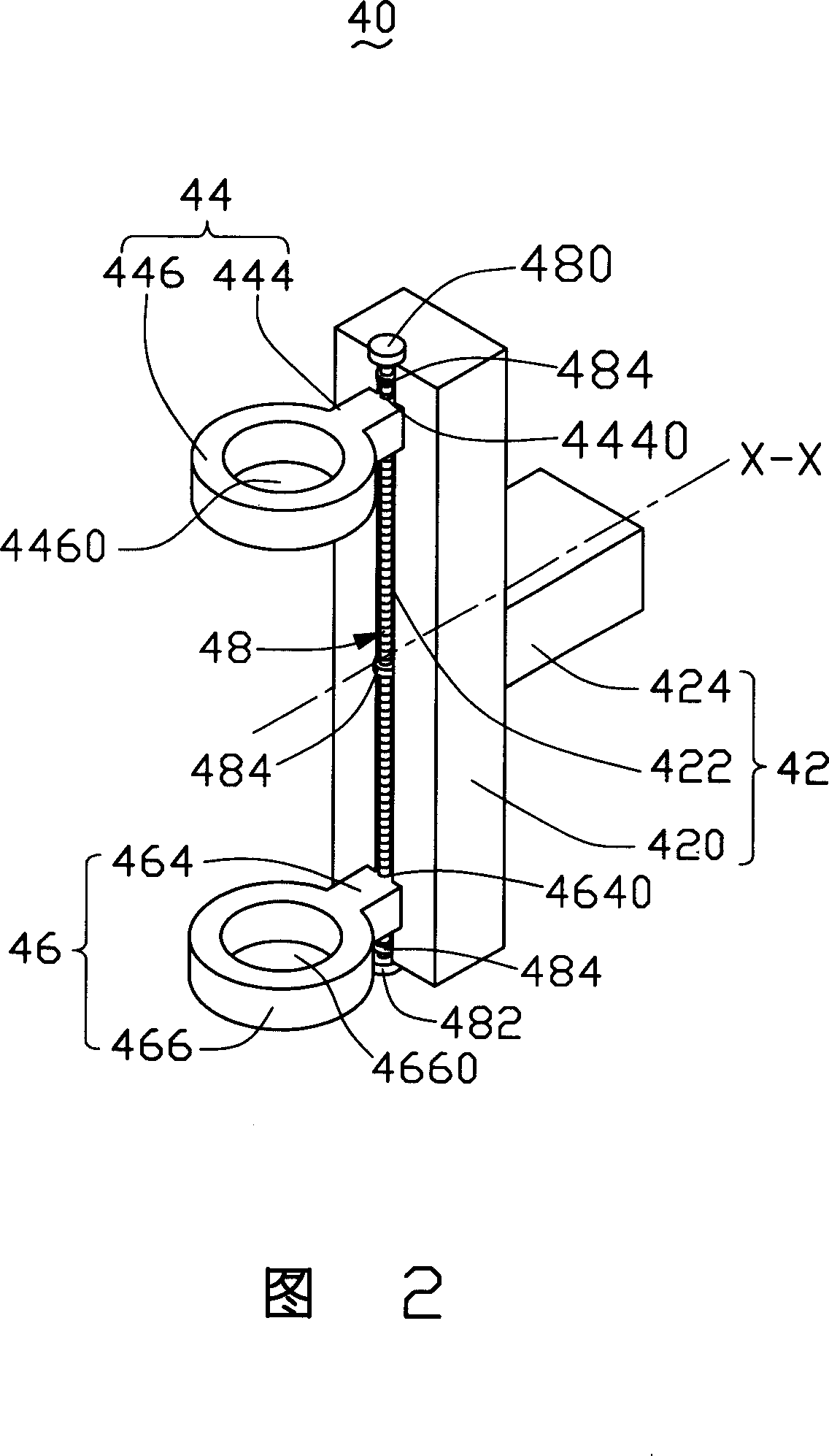

[0013] Referring to FIG. 2, the clamping device 40 provided by the embodiment of the present invention includes a supporting mechanism 42, clamping arms 44 and 46, and a driving mechanism 48.

[0014] The supporting mechanism 42 is used to support the clamping arms 44 and 46. The supporting mechanism 42 includes a main body 420, a sliding groove 422 and a supporting rod 424. The sliding groove 422 is provided on one side of the main body 420. The supporting rod 424 may be provided on the other side of the main body 420 opposite to the sliding groove 422. The supporting rod 424 and the main body 420 are integrated. When an external force acts on the supporting rod 424, the supporting rod 424 can drive the main body 420 rotates around the central axis XX of the support rod 424 together. The support rod 424 can be a prism, a cylinder, etc., and ca...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com