Automatic mold separating device for upper mold and lower mold of contact lens

A contact lens and mold separation technology, applied to other household appliances, optical components, household appliances, etc., can solve the problems of low production efficiency of contact lenses, unsuitable for mass production, rising labor costs, etc., to reduce the risk of dust exposure , Improve yield and avoid lens damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

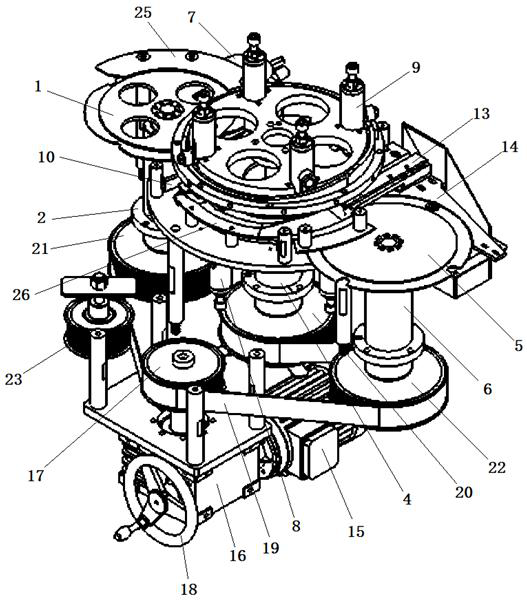

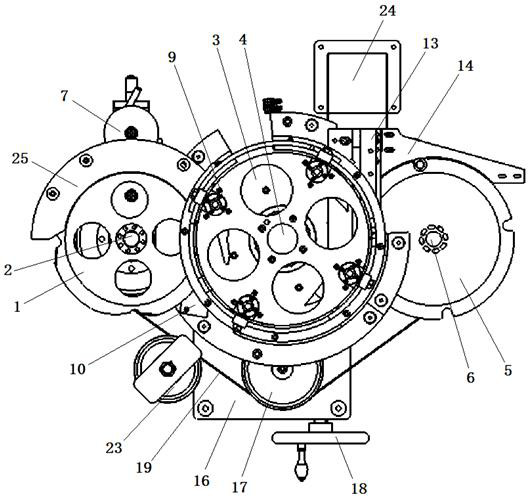

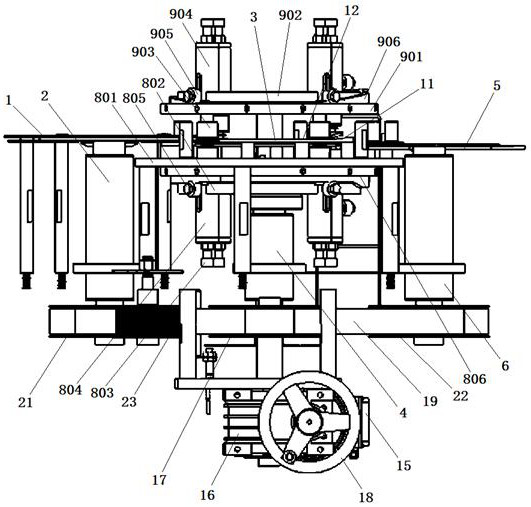

[0031] The present invention will be described in detail below with reference to the accompanying drawings and in combination with embodiments. The descriptions here are used to provide a further understanding of the present invention and constitute a part of the application. The exemplary embodiments of the present invention and their descriptions are used to explain the present invention and do not constitute improper limitations to the present invention.

[0032] see Figure 1-3 As shown, an automatic mold splitting device for upper and lower molds of contact lenses, including a feeding turntable 1, a feeding turntable rotation axis 2, a mold splitting turntable 3, a mold splitting turntable rotation axis 4, a discharge turntable 5, and a discharge turntable rotation axis 6 , Feeding cutter 7, lower mold pressing mechanism 8, upper mold pressing mechanism 9, upper and lower mold limit block 10, main mold splitting knife 11, auxiliary mold splitting knife 12, upper mold disc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com