Closed dustproof and discharging device and method

A discharge device and dust-proof technology, which is applied in the field of material discharge devices, can solve the problems of endangering the health of workers, low efficiency, poor dust capture efficiency, etc., and meet the requirements of saving equipment installation and operating space and reducing hoisting height , Improve the effect of portability and applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In conjunction with the accompanying drawings, the technical solution will be further described.

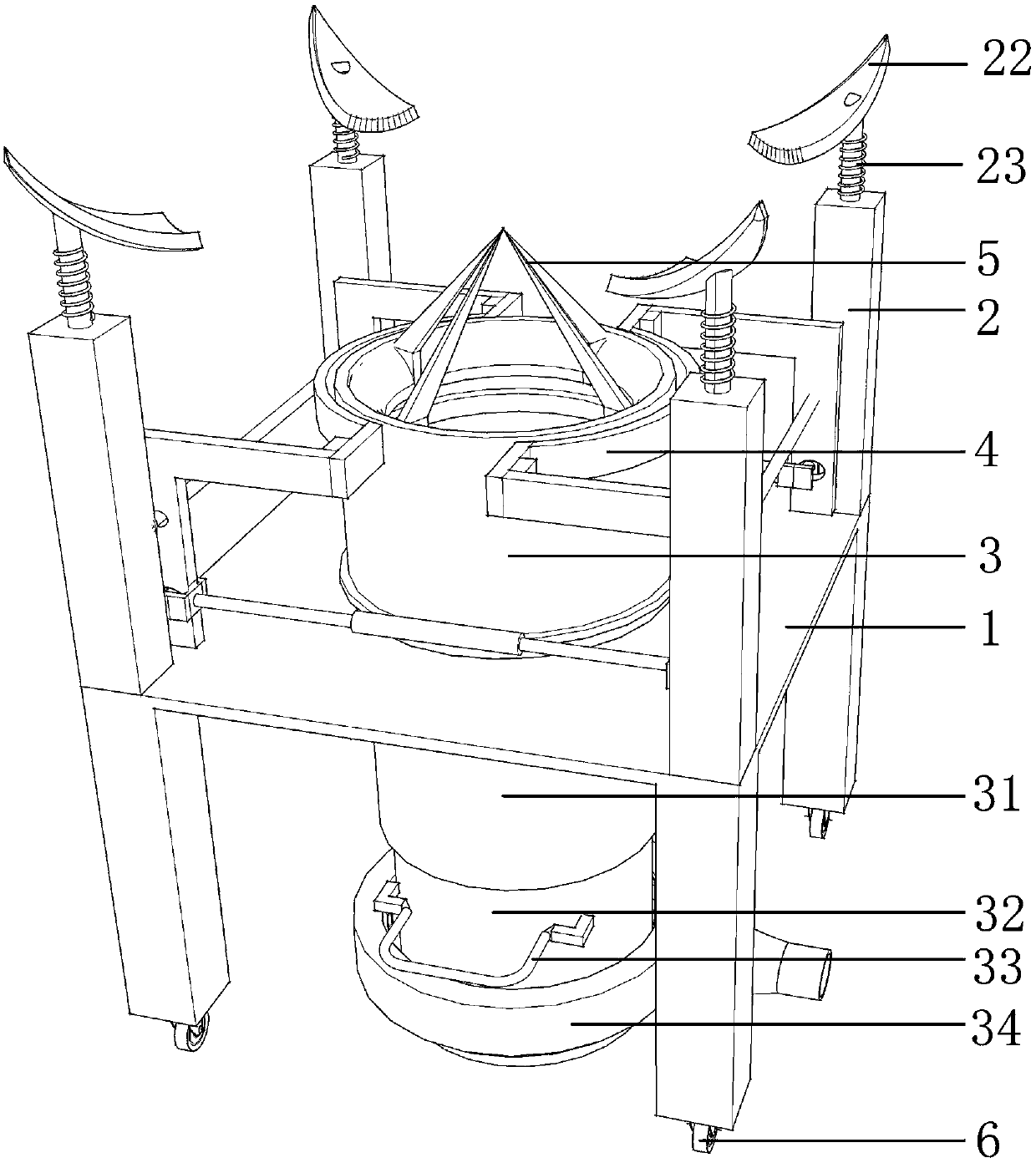

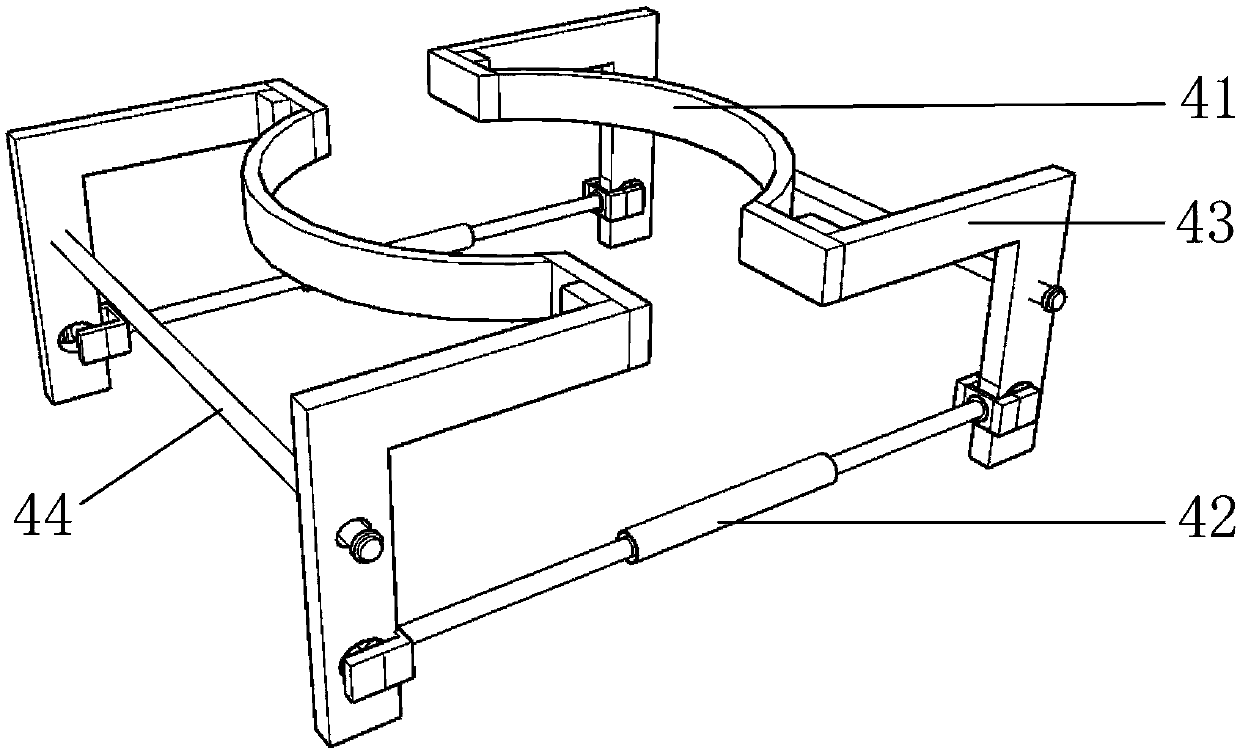

[0034] A sealed dust-proof unloading device includes a vehicle frame platform 1, a buffer frame 2, an unloading sleeve 3, a bag clamping device 4, a bag breaking blade tip 5 and a universal wheel 6.

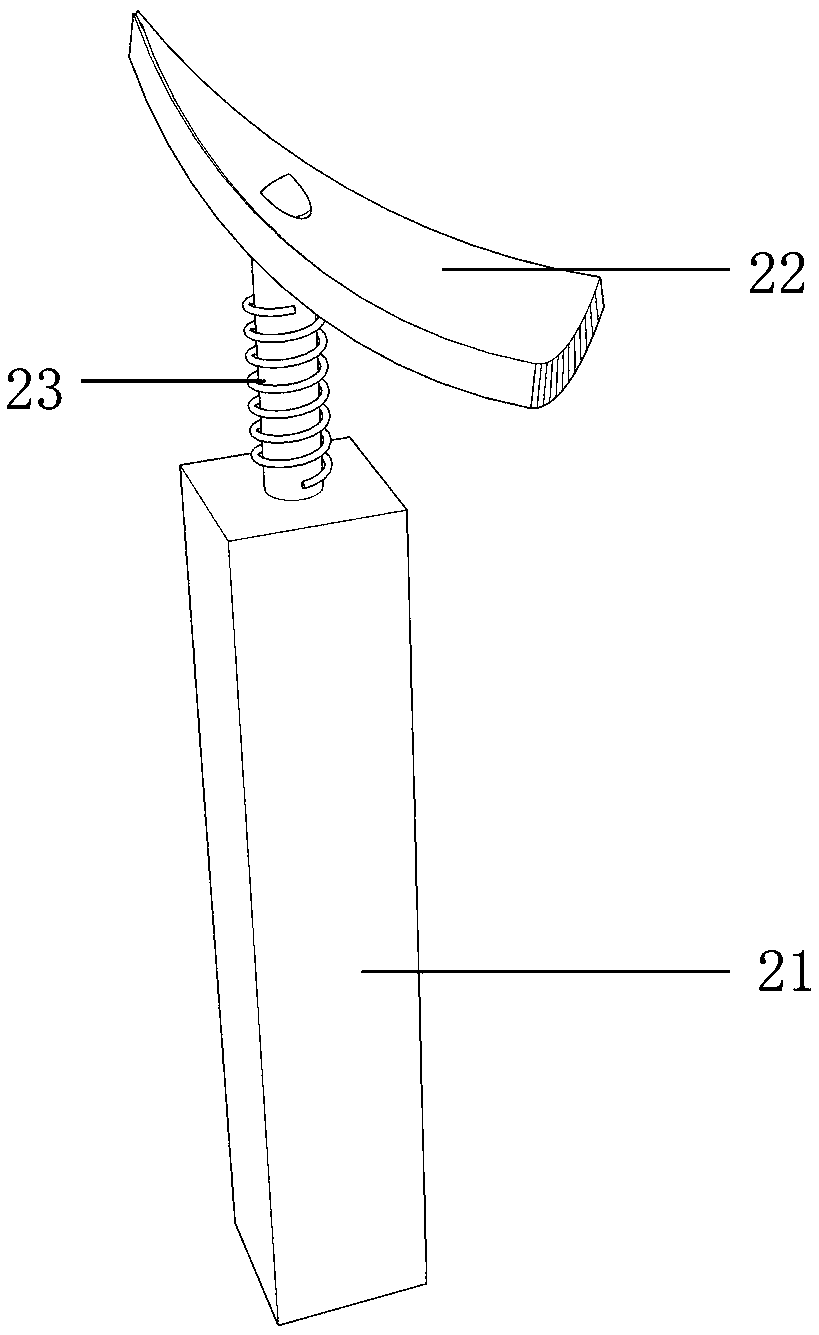

[0035] The buffer frame 2 includes a buffer frame column 21 , a buffer plate 22 and a buffer spring 23 . The buffer frame column is welded to the four corners of the unloading device frame platform. The buffer frame is used to buffer and protect the bag clamping device and the bag breaking blade.

[0036] The unloading sleeve 3 includes a two-stage telescopic sleeve. The inner wall of the first-level sleeve 31 is provided with a circular inner protrusion, which is used for fixing the bag-breaking edge 5, passing through the vehicle frame platform 1 of the unloading device and being welded on the vehicle frame platform. A handle 33 is installed in the middle section of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com