Method and device for preventing dust emission of baiting chute

A chute and dust technology is applied in the field of preventing dust from the feeding chute, which can solve the problems of harming the health of workers, unsatisfactory use effect, environmental pollution, etc., and achieves the effect of protecting health, simple structure and improving working environment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

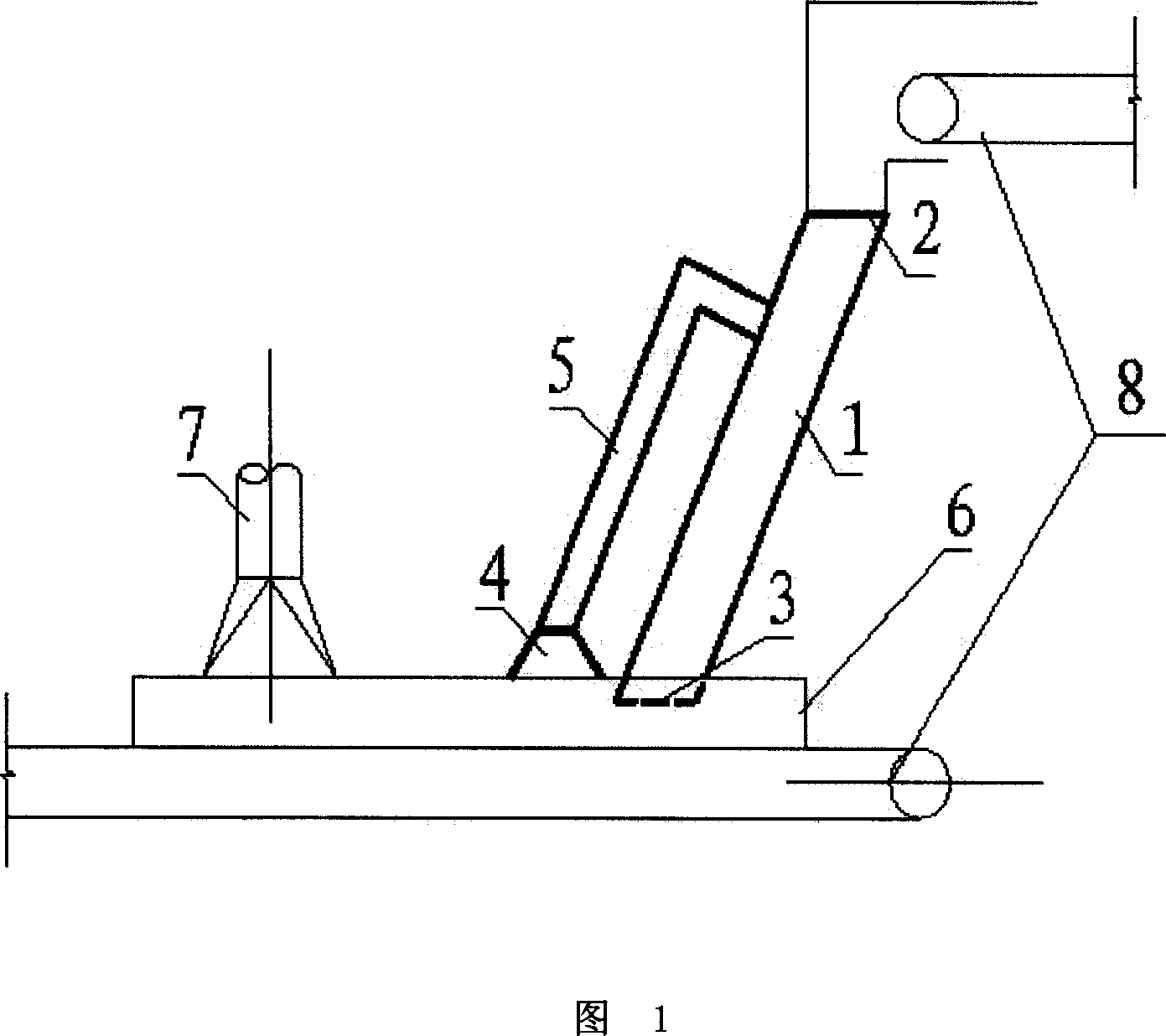

[0011] Embodiments of the present invention: when performing dust prevention treatment on the existing feeding chute, the air pressure at the outlet of the feeding chute is greater than the pressure difference at the inlet of the feeding chute. The dust-containing air at the outlet of the material chute is pressed back into the material chute near the inlet through a connecting pipe connected to the inlet of the material chute, which can effectively reduce and prevent Dust generated at the outlet of the feeding chute.

[0012] During production, a connecting pipe 5 communicating with the inner cavity of the feeding chute 1 is connected on the existing feeding chute 1 near its feeding port 2, and the lower port of the connecting pipe 5 is arranged near the lower port. There are 3 outlets of the material chute 1; in order to more effectively collect the dusty air near the outlet 3, a trumpet-shaped reducer 4 can be connected to the lower port of the connecting pipe 5; in order t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com