Horizontal plastic injection forming machine injection head

An injection molding machine and injection head technology, applied in the field of injection nozzles and injection heads, can solve the problems of fluid material leakage, material leakage, poor sealing performance at the feeding port, etc., and achieve the effect of preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

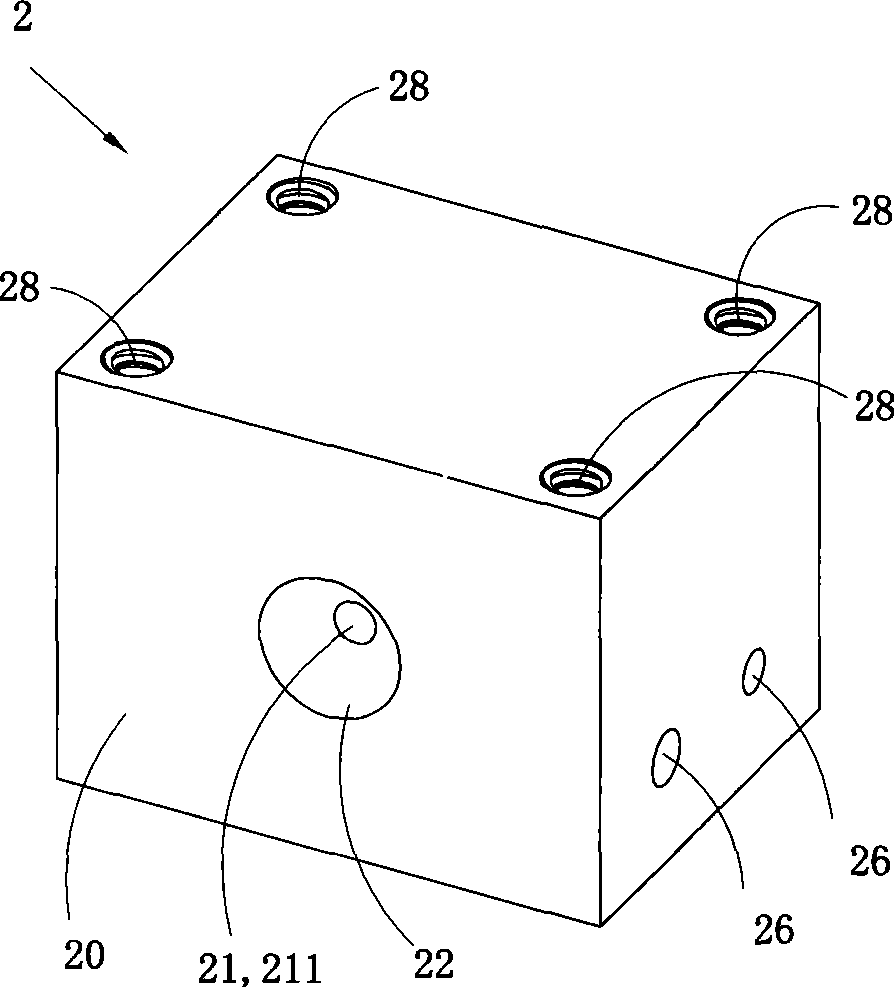

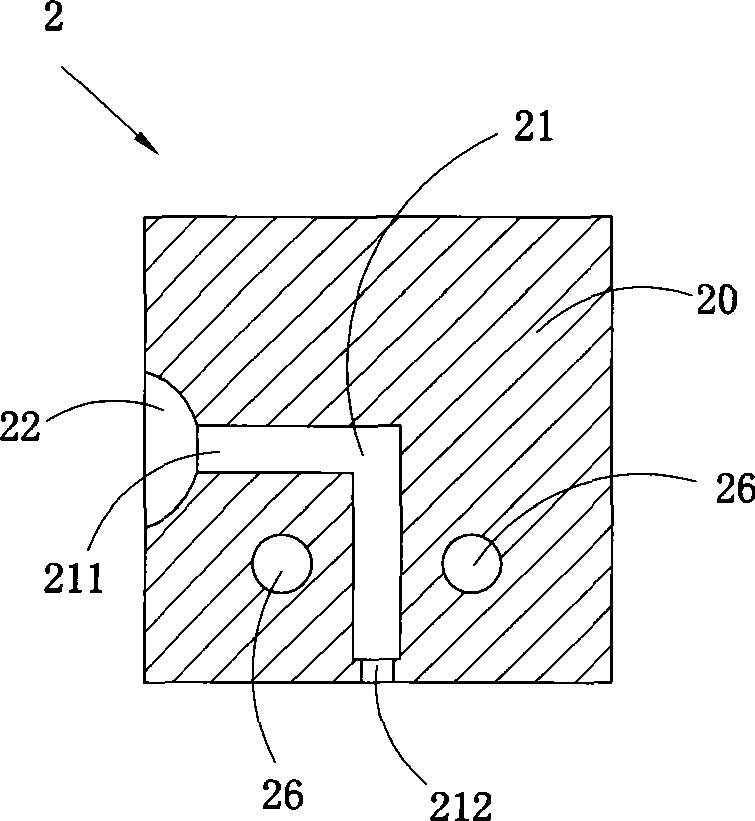

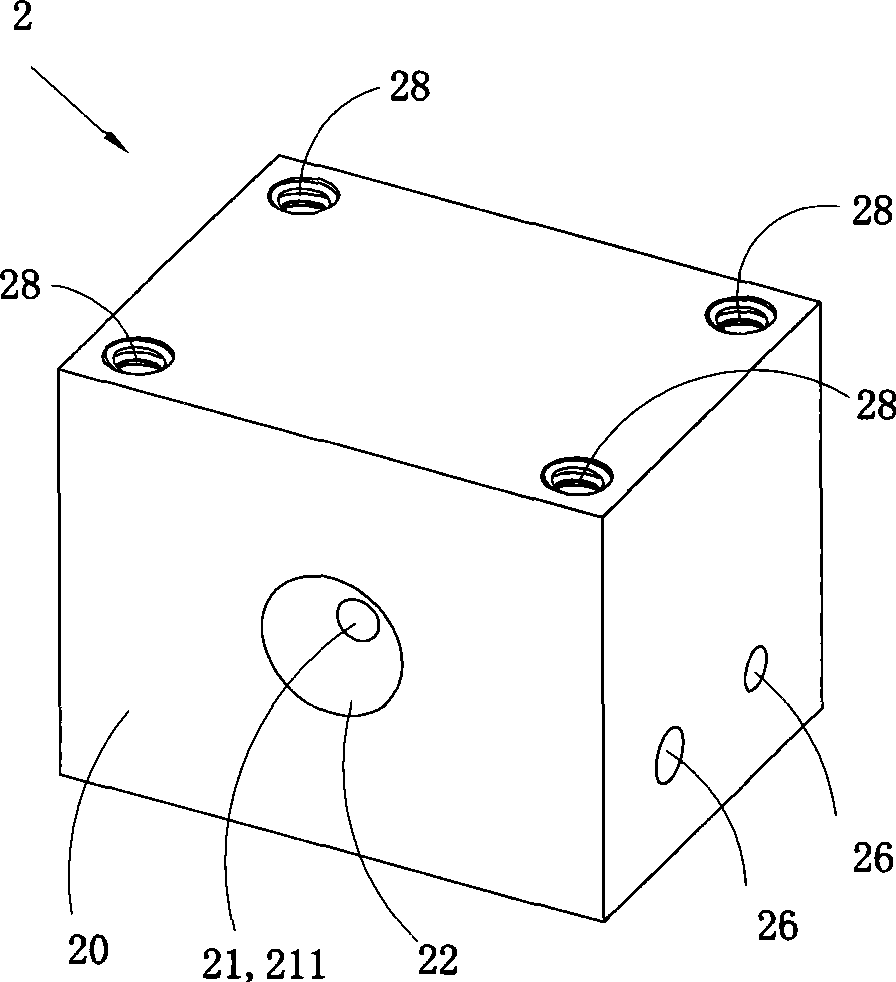

[0052] Figure 1 to Figure 2 A first embodiment of the invention is shown in which, figure 1 It is a three-dimensional structural schematic diagram of the first structure of the present invention. figure 2 yes figure 1 half cutaway view.

[0053] This embodiment is an injection head 2 used for a horizontal plastic injection molding machine, and its body 20 is provided with an injection channel 21, and the injection channel 21 has a material inlet 211 and a material injection port 212; the injection The head body 20 is provided with a feed connection part 22 at the feed port 211, the basic shape of the feed connection part 22 is a hemispherical groove with a concave spherical surface or a conical groove with a concave conical surface, The feed opening 211 is located at the center of the feed connection part 22 .

[0054] See figure 1 , The front of the injection head body 20 is provided with two through holes 26, and the through holes 26 are used for inserting an electric...

Embodiment 2

[0058] Figure 3 to Figure 7 A second embodiment of the invention is shown in which, image 3 It is a three-dimensional structural schematic diagram of the second structure of the present invention. Figure 4 yes image 3 A schematic diagram of the three-dimensional structure of the injection head shown when viewed from another angle. Figure 5 yes image 3 Half-cut view of the injection head shown. Image 6 yes Figure 5 The partially enlarged schematic diagram at middle F. Figure 7 yes image 3 A half-section view of the injection nozzle in the injection head shown.

[0059] This embodiment is basically the same as Embodiment 1, the difference is: see Figure 3 to Figure 7 , the injection nozzle 1 that can inject material and prevent material leakage is inserted in the injection port 212 of the injection channel 21. The basic shape of the injection nozzle 1 is a T-shape with a large top and a small bottom, the upper part is a sealing part 11, and the lower part is ...

Embodiment approach

[0061] Figure 8 to Figure 17 A third embodiment of the invention is shown, in which Figure 8 It is a schematic diagram of the three-dimensional structure of the third structure of the present invention. Figure 9 yes Figure 8 The schematic diagram of the three-dimensional structure of the injection head when viewed from another angle. Figure 10 yes Figure 8 The schematic diagram of the three-dimensional structure of the injection head body in the injection head shown. Figure 11 yes Figure 10 Front view of the injection tip body shown. Figure 12 yes Figure 11 B direction view. Figure 13 yes Figure 12 C-C cross-sectional view of . Figure 14 yes Figure 12 D-D cross-sectional view of . Figure 15 is Figure 9 The schematic diagram of the three-dimensional structure of the injection coupler in the injection head shown. Figure 16 yes Figure 9 Half-cut view of the injection head shown. Figure 17 is adopted Figure 9 A plastic injection molding machine m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com