Silencer for scroll compressor

A scroll compressor and muffler technology, which is applied in the direction of machines/engines, mechanical equipment, liquid fuel engines, etc., can solve the problems of inaccurate isolation of the muffler, reduced performance and reliability of the scroll compressor, and no separation of the muffler

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

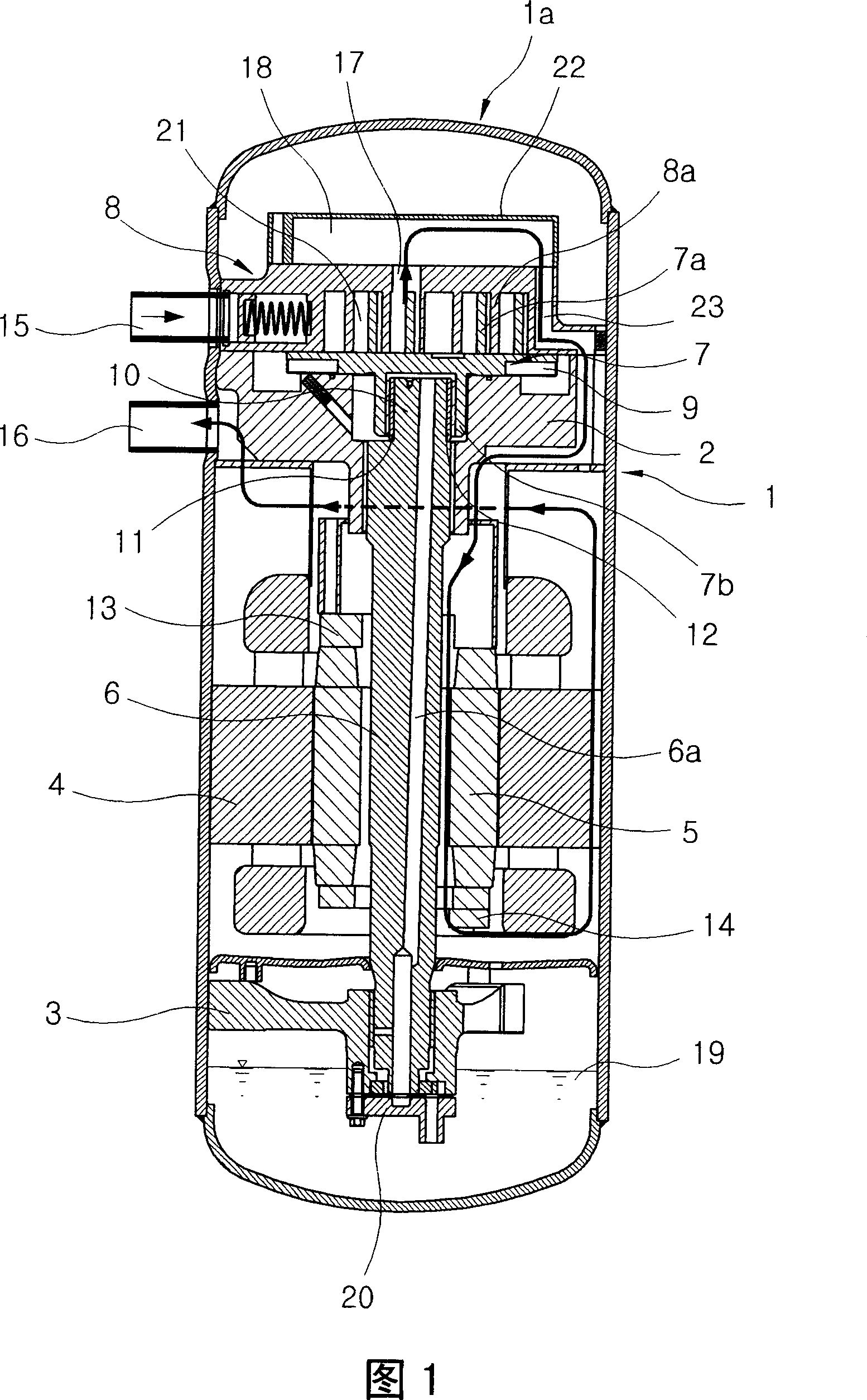

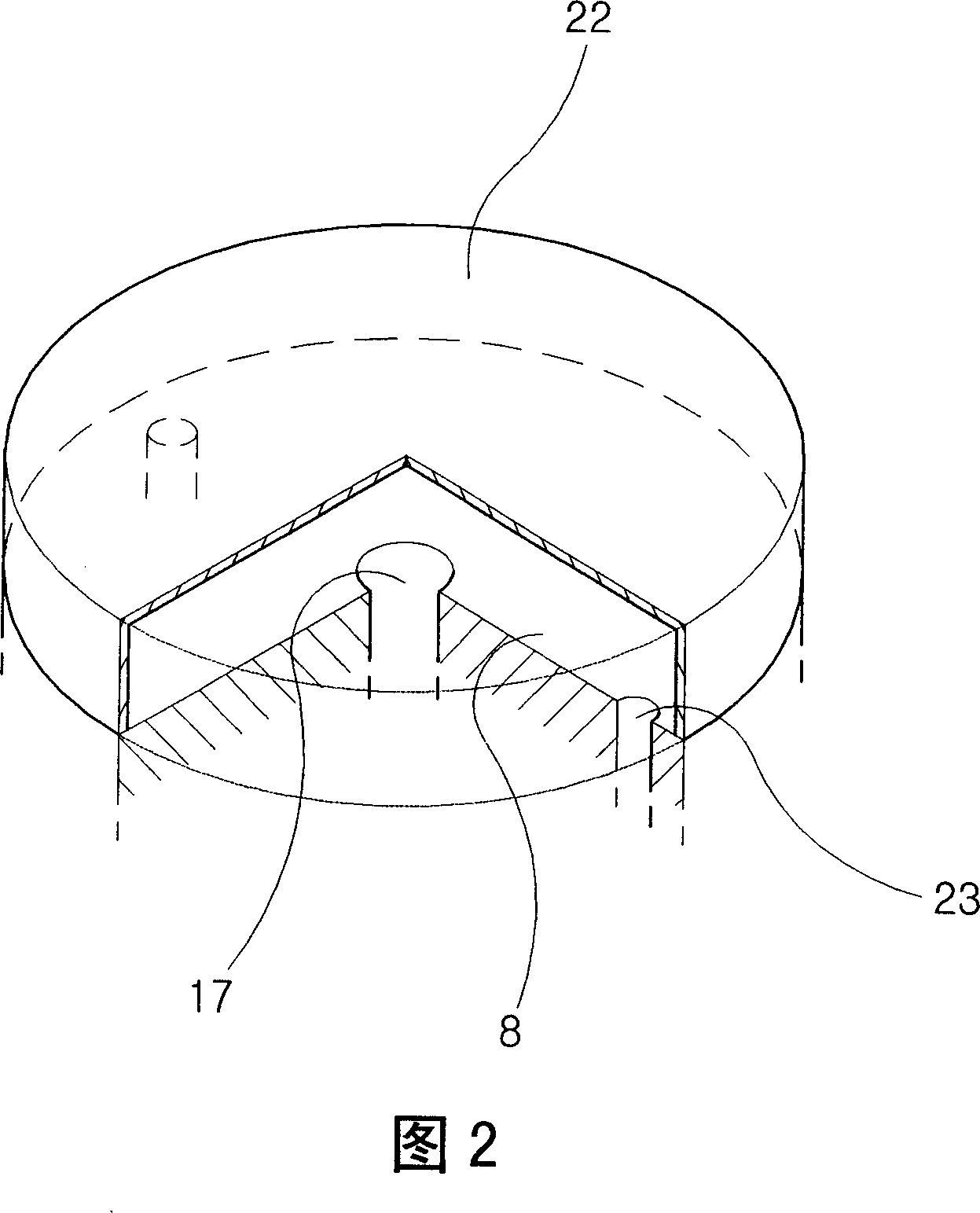

[0030] The configuration of the present invention will be described in detail below with reference to the drawings.

[0031] In the following description, constituent elements of the present invention are denoted by the same reference numerals as their corresponding elements in the prior art.

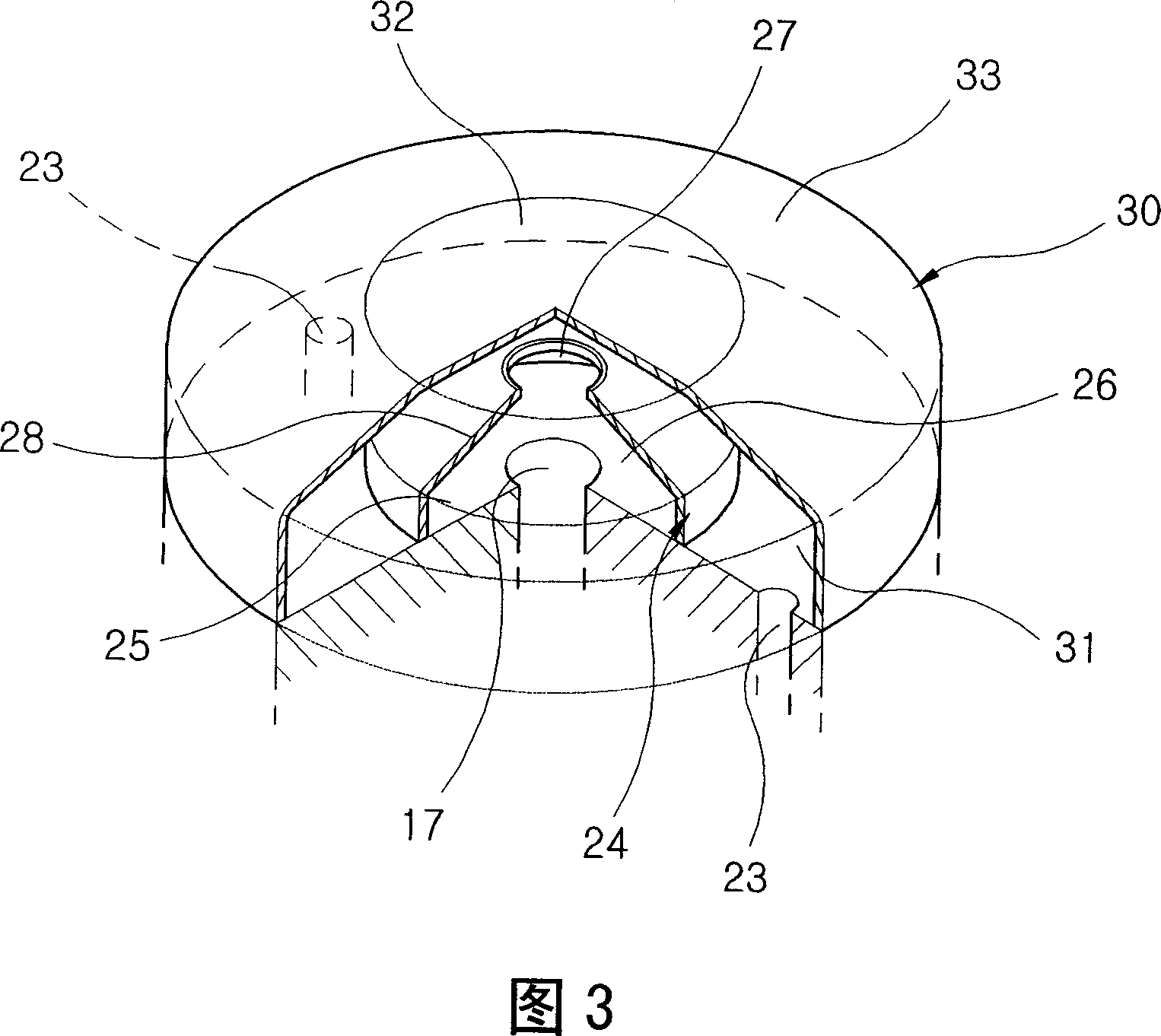

[0032] Referring to FIG. 3, this figure is a partially cutaway perspective view showing a muffler according to a first embodiment of the present invention. The muffler includes a first muffler 24 and a second muffler 30 . The first muffler 24 internally defines a pair of chambers located above the outlet 17 of the fixed scroll 8, the chambers communicate with the outlet 17, and a gas passage hole 27 is formed at the center of the upper end of the first muffler. The second muffler 30 is disposed around the first muffler 24 and spaced apart from the gas passage hole 27 of the first muffler 24 . The second muffler 30 internally defines a chamber including the guide passage 23 of the fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com