Loose tobacco compression type baking technics in the baking room

A technology of curing technology and curing room, which is applied in the field of flue-cured tobacco curing technology, which can solve the problems of badly cured tobacco, non-shrinkage, and poor curing rate of tobacco leaves, so as to reduce labor costs, simplify the curing process, and improve the curing process. The effect of craft

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

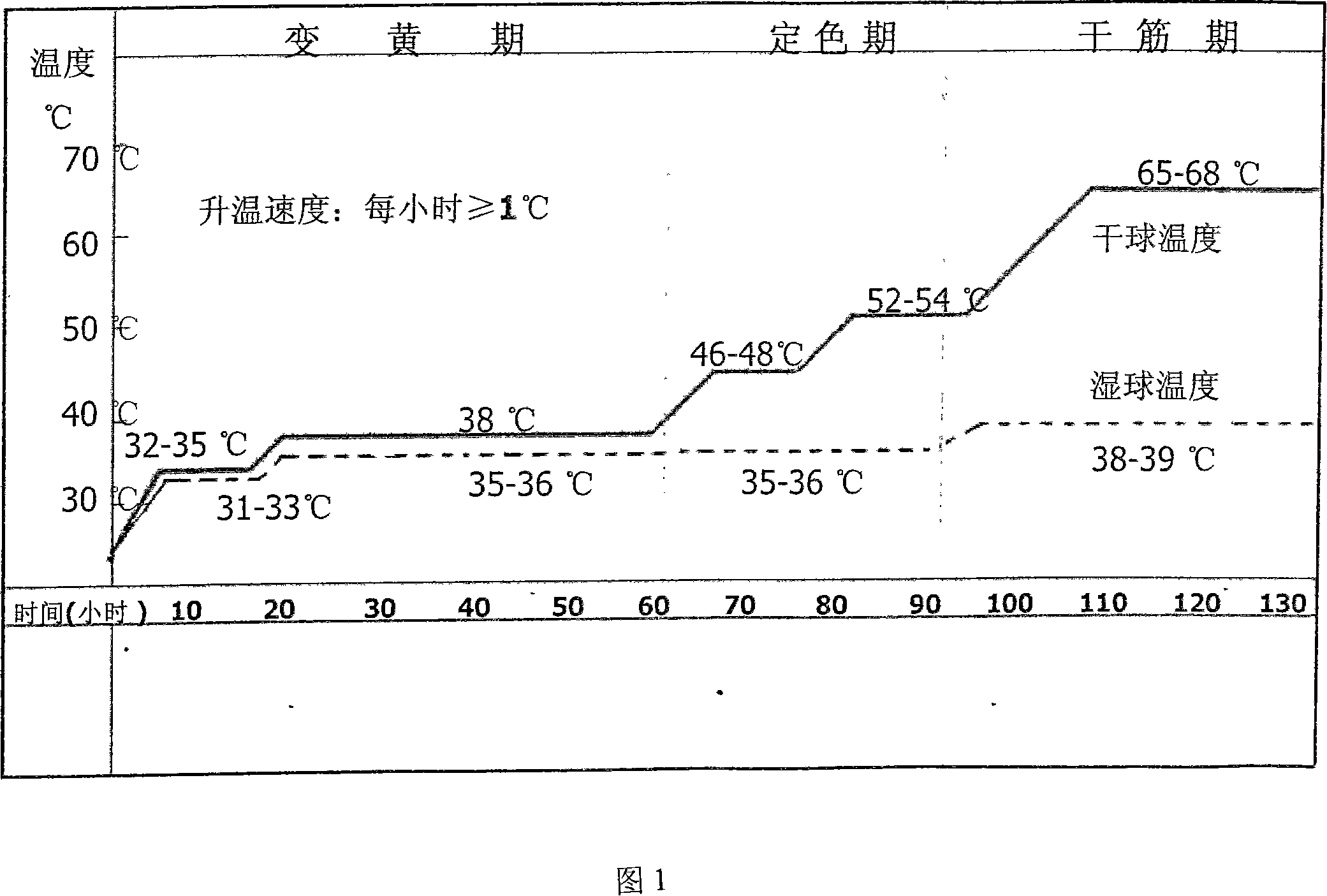

[0014] Embodiment 1 To the loose leaf baking of a certain local tobacco in Guizhou Province, adopt the following baking process:

[0015] After loading the smoke in the barn, ignite and bake for 15-20 hours to enter the yellowing stage.

[0016] (1) Baking operation technology in the yellowing stage

[0017] Operation requirements: the change of tobacco leaves reaches full yellow (full yellowing), and the leaves become soft; in the later stage of yellowing, a small amount of moisture is drained first, and then the temperature is raised to fix the color; the baking guidance time of the yellowing stage: 45-50 hours for the lower tobacco leaves, and 45 to 50 hours for the middle and upper tobacco leaves. Tobacco leaves are 55-65 hours.

[0018] Operation method: In the early stage of yellowing, the dry bulb temperature is 32 ℃ ~ 35 ℃, and bake at a steady temperature for 10 to 25 hours. After the tobacco leaves are slightly lodging, the dry bulb temperature is raised to 38 ℃; in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com