Automobile threshold

A threshold, automotive technology, applied in vehicle components, superstructure, superstructure sub-assemblies and other directions, can solve the problems of high production cost, endangering the personal safety of passengers, and high scrap rate of parts, and achieves mature processing technology and production technology. The effect of reducing maintenance costs and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

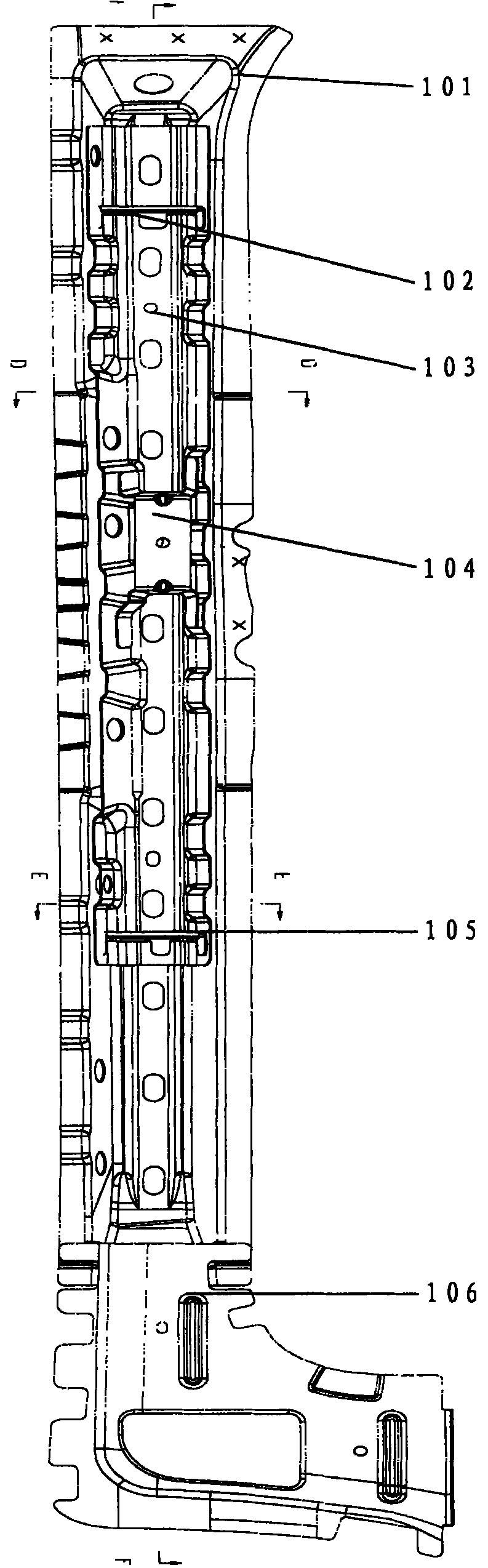

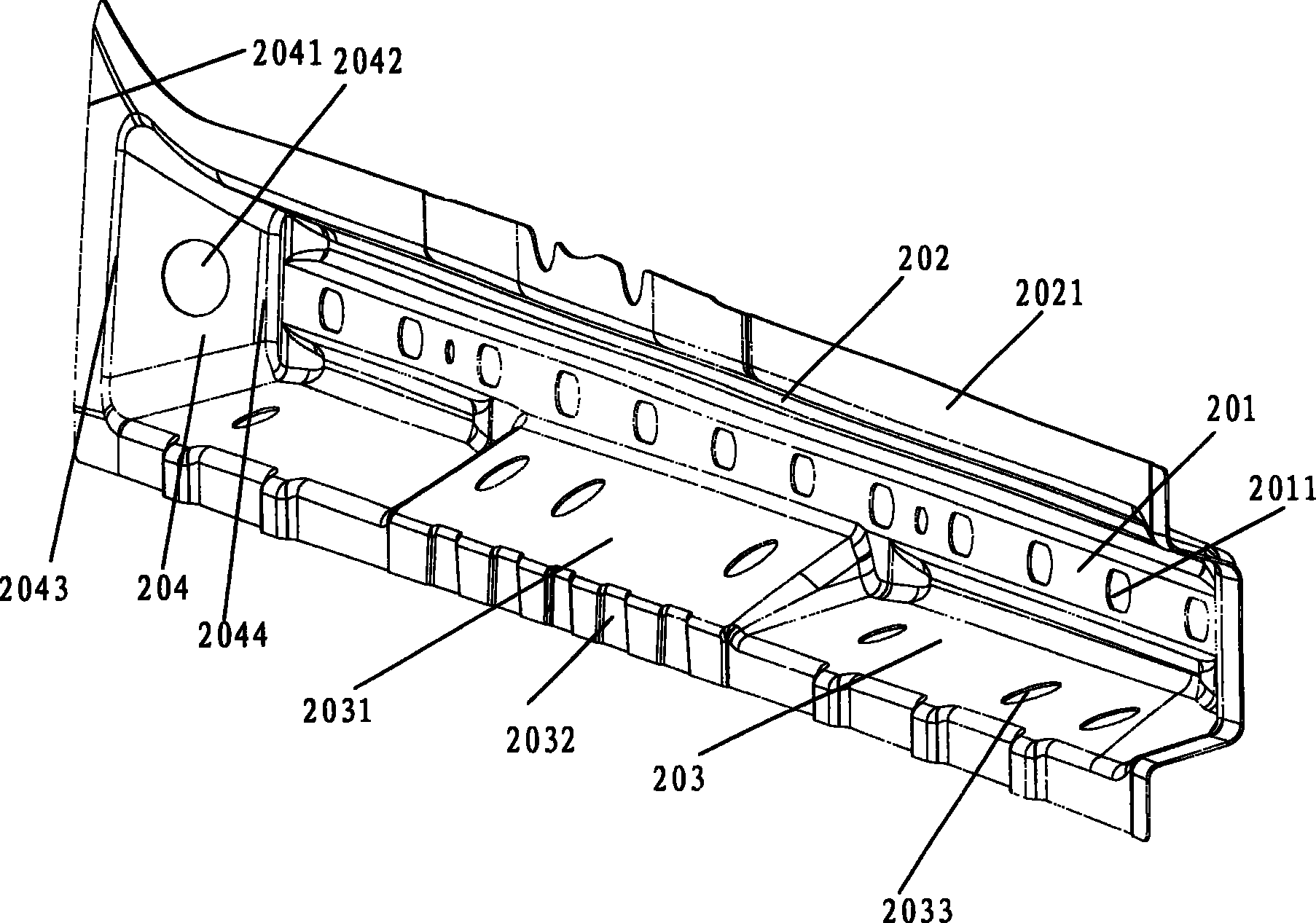

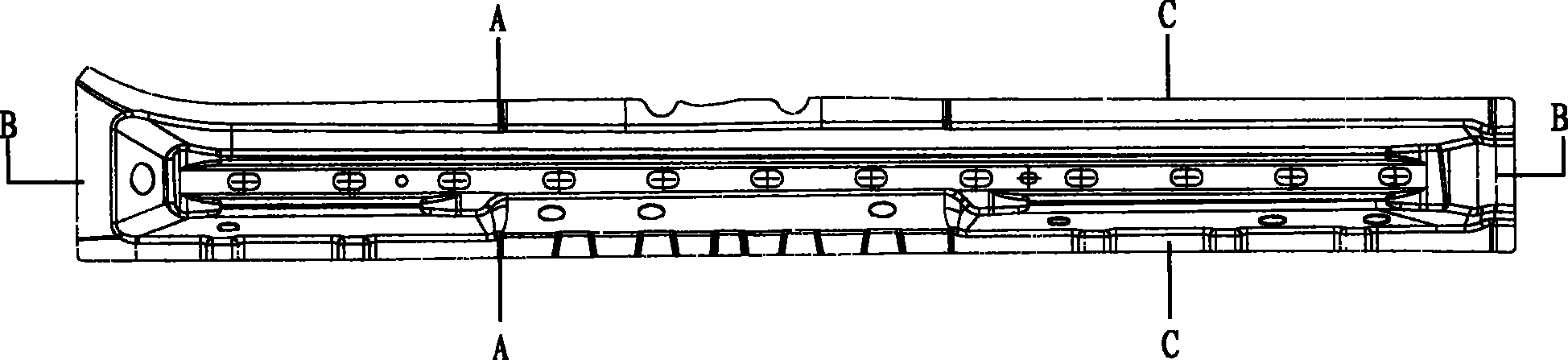

[0036] see figure 1 , is a schematic diagram of the automobile threshold of the present invention, and the automobile threshold of the present invention includes a lower threshold reinforcement plate 101, a lower threshold reinforcement inner panel 102, a lower threshold reinforcement inner panel front bracket 105, a lower threshold reinforcement inner panel middle bracket 104, and a lower threshold reinforcement inner panel rear bracket 103 and the lower inner panel 106 of the front pillar.

[0037] The lower sill reinforced inner panel 102 is fixed inside the lower sill reinforced inner panel 101 through the lower sill reinforced inner panel front bracket 105, the lower sill reinforced inner panel middle bracket 104, the lower s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com