A quick installation method for a monitor outside a finishing factory

An installation method and monitor technology, which is applied in the direction of supporting machines, mechanical equipment, machine platforms/brackets, etc., can solve problems such as camera loosening, time-consuming and physical effort, and duckbill bracket corrosion, so as to improve service life and avoid stress damage, stability-enhancing effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

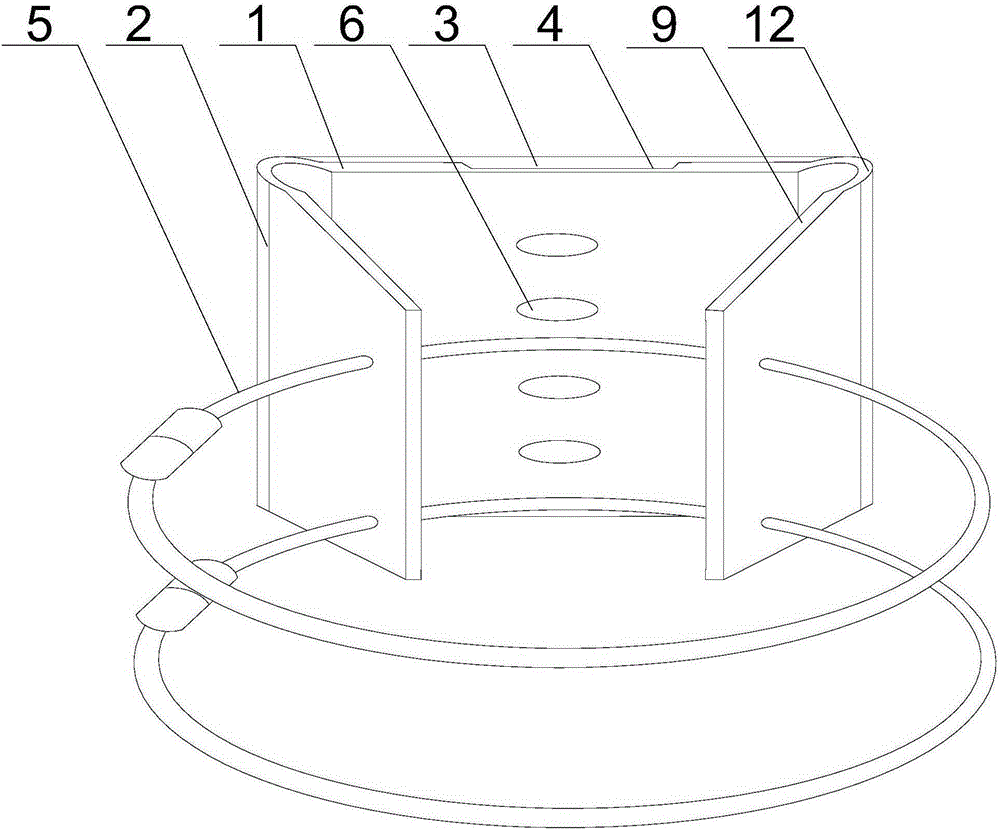

[0026] Such as Figure 1 to Figure 3 As shown, this embodiment includes the following steps:

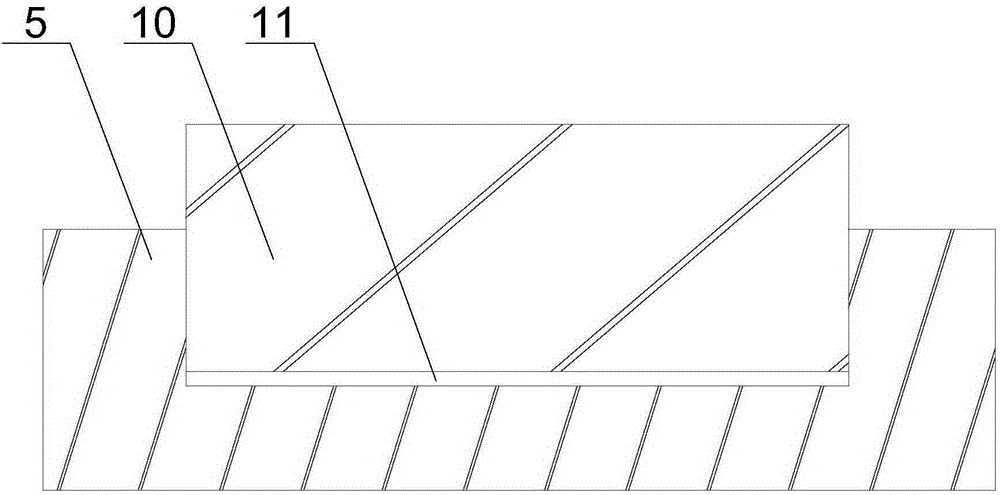

[0027] A First fix the bottom plate and the baffle on the rod-shaped support structure on the city street through the clamp, set a groove extending vertically downward on the bottom plate, and set the protrusion that matches the shape of the groove slidingly in the groove , and the bracket of the monitor can be installed on the mounting plate by means of bolt fixing or welding, and the groove width of the groove gradually decreases along the vertical direction, so that the mounting plate can automatically Snap into the groove to ensure the stability of the monitor;

[0028] B The active connection between the mounting plate and the bottom plate has changed the traditional installation method where the monitor bracket is directly welded to the bottom plate. When replacing or repairing the monitor, you only need to take the mounting plate out of the groove and then perform maintenance...

Embodiment 2

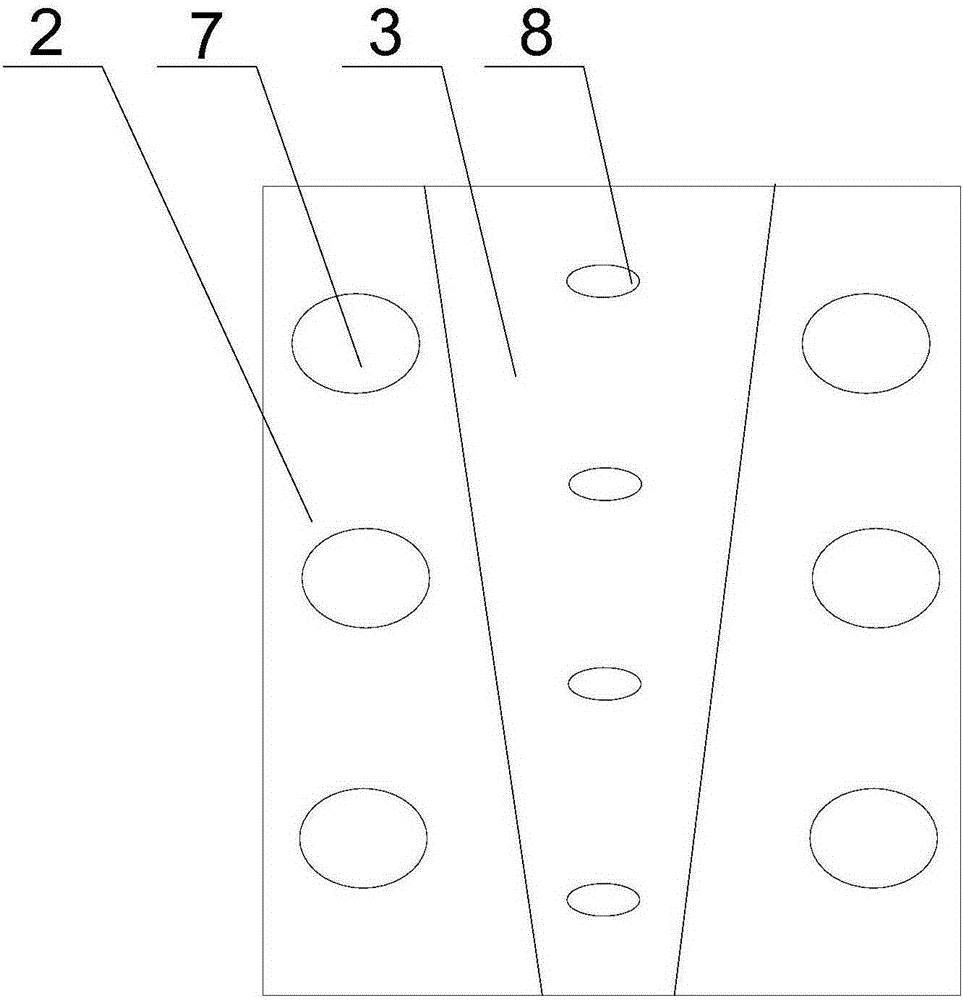

[0033] Such as figure 2 and image 3 As shown, in this embodiment, on the basis of Embodiment 1, a plurality of adjustment holes 6 arranged longitudinally are opened in the groove 4, and threaded holes 8 corresponding to the adjustment holes 6 are opened on the protrusion 3, and the protrusions 3 is fixed on the bottom plate 1 by bolts. Due to the height limitation of the existing rod-shaped support structure, it is necessary to fine-tune the fixed bracket. The fixed plate can slide freely on the bottom plate 1 through the protrusion 3. After the fixed plate moves up and down to a certain distance, the protrusion 3 and the The groove 4 is fixed, thereby realizing the fine adjustment of the fixed plate and the monitor.

[0034] Two rows of mounting holes 7 parallel to the protrusion 3 are opened on the mounting plate 2 , and the two rows of mounting holes 7 are arranged symmetrically on both sides of the protrusion 3 . The traditional monitor bracket is generally directly w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com