Fin structure and method of manufacturing fin transistor adopting the fin structure

一种鳍式结构、结晶的技术,应用在半导体/固态器件制造、电固体器件、半导体器件等方向,能够解决鳍式结构成本高、鳍式结构均匀性降低等问题

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

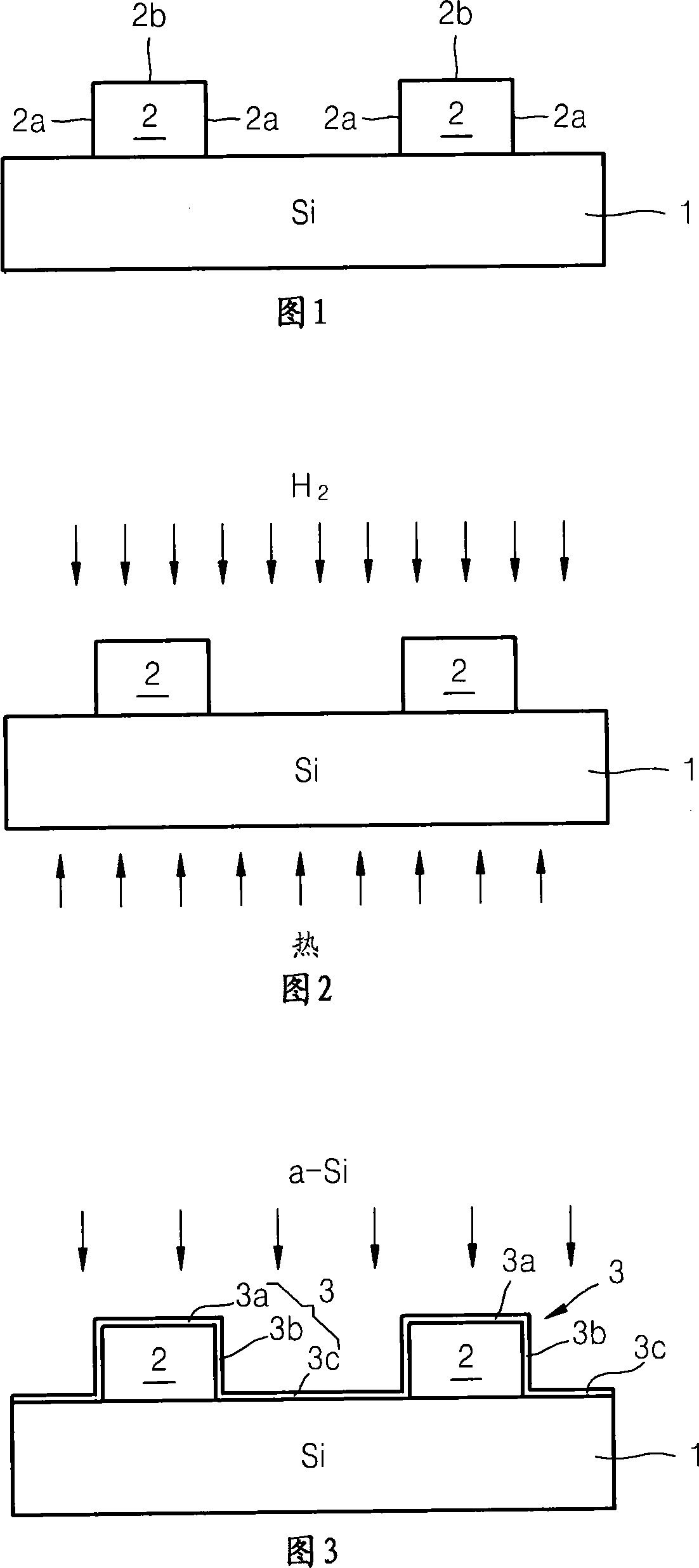

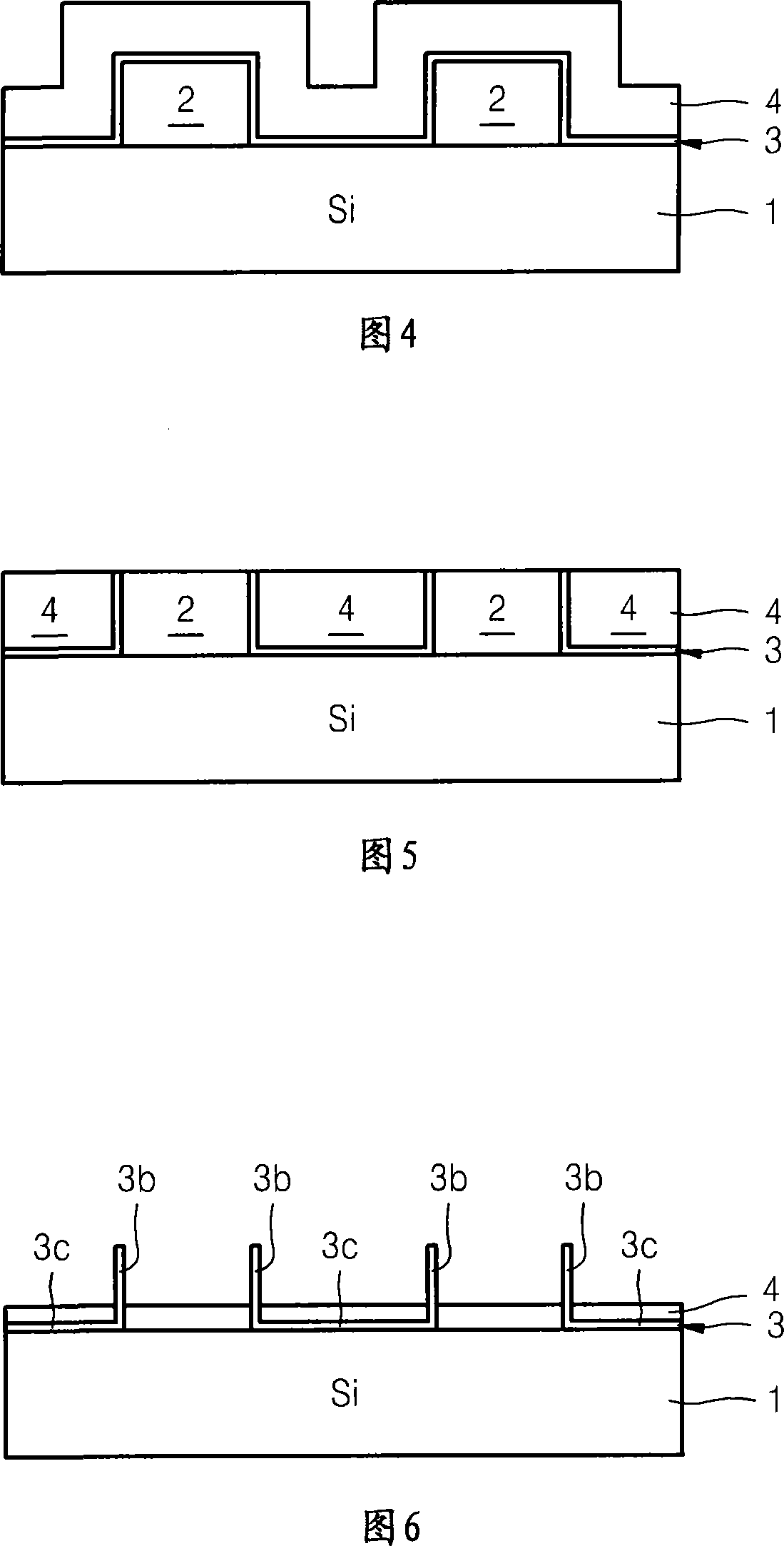

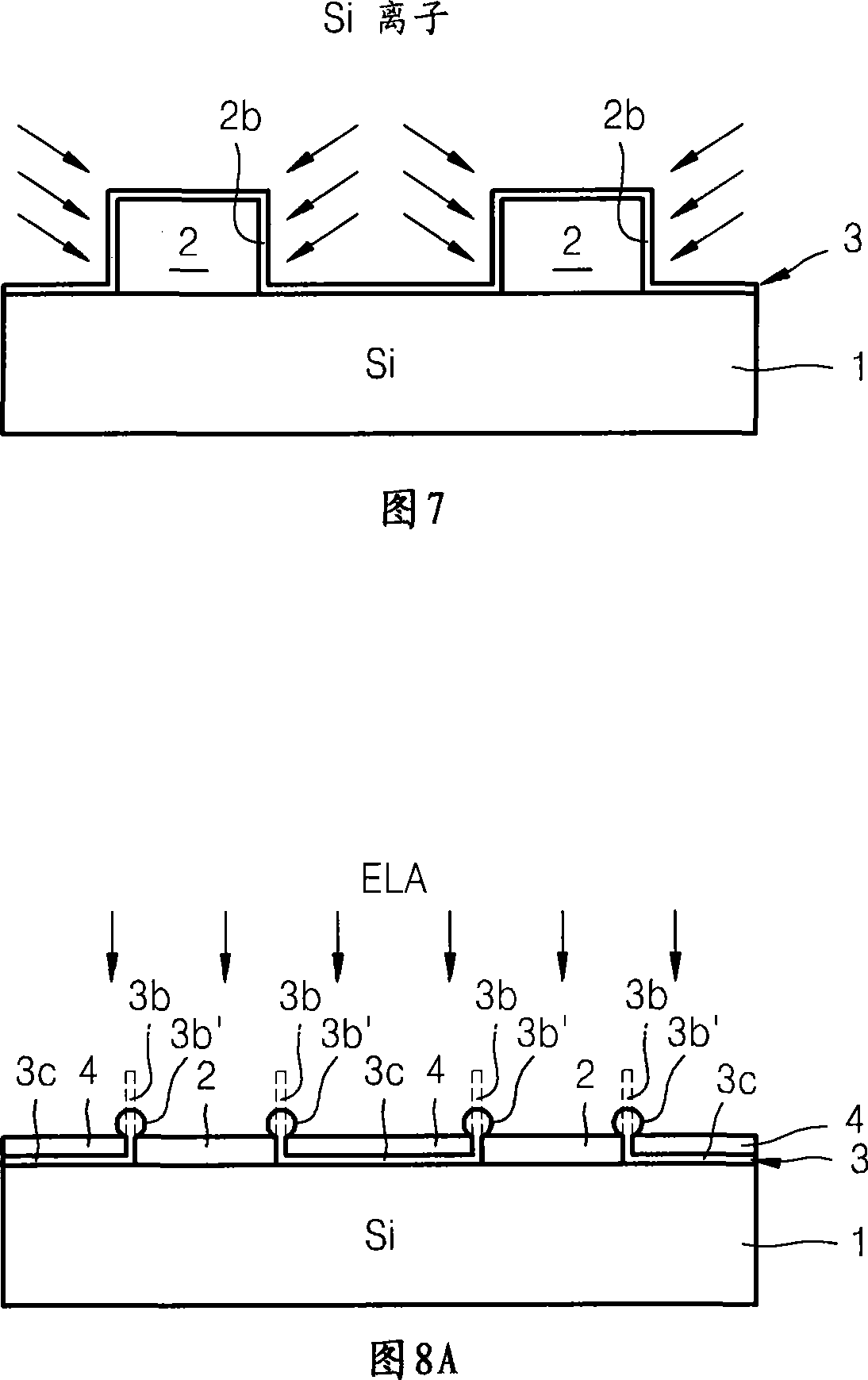

[0019] A method of manufacturing a fin structure according to the present invention will now be described with reference to the accompanying drawings. This method corresponds to the method of manufacturing a fin-type active region of a fin-type transistor. Therefore, the method of manufacturing a fin transistor according to the present invention will be easily understood from this method.

[0020] 1 to 6 are cross-sectional views illustrating a process of manufacturing a fin structure according to an embodiment of the present invention. In the embodiments of the present invention, silicon will be described as an application of a material forming a semiconductor layer.

[0021] As shown in FIG. 1 , a plurality of mesa structures 2 having a predetermined length are formed on a silicon substrate 1 . The mesa structure 2 has an upper surface 2b and side surfaces 2a formed beside the upper surface 2b. The distance between the mesa structures 2 must be properly adjusted according...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com