Liquid-solid two-phase current scouring and cavitation composite abrasion test machine

A wear test, two-phase flow technology, applied in the direction of testing wear resistance, weather resistance/light resistance/corrosion resistance, measuring device, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

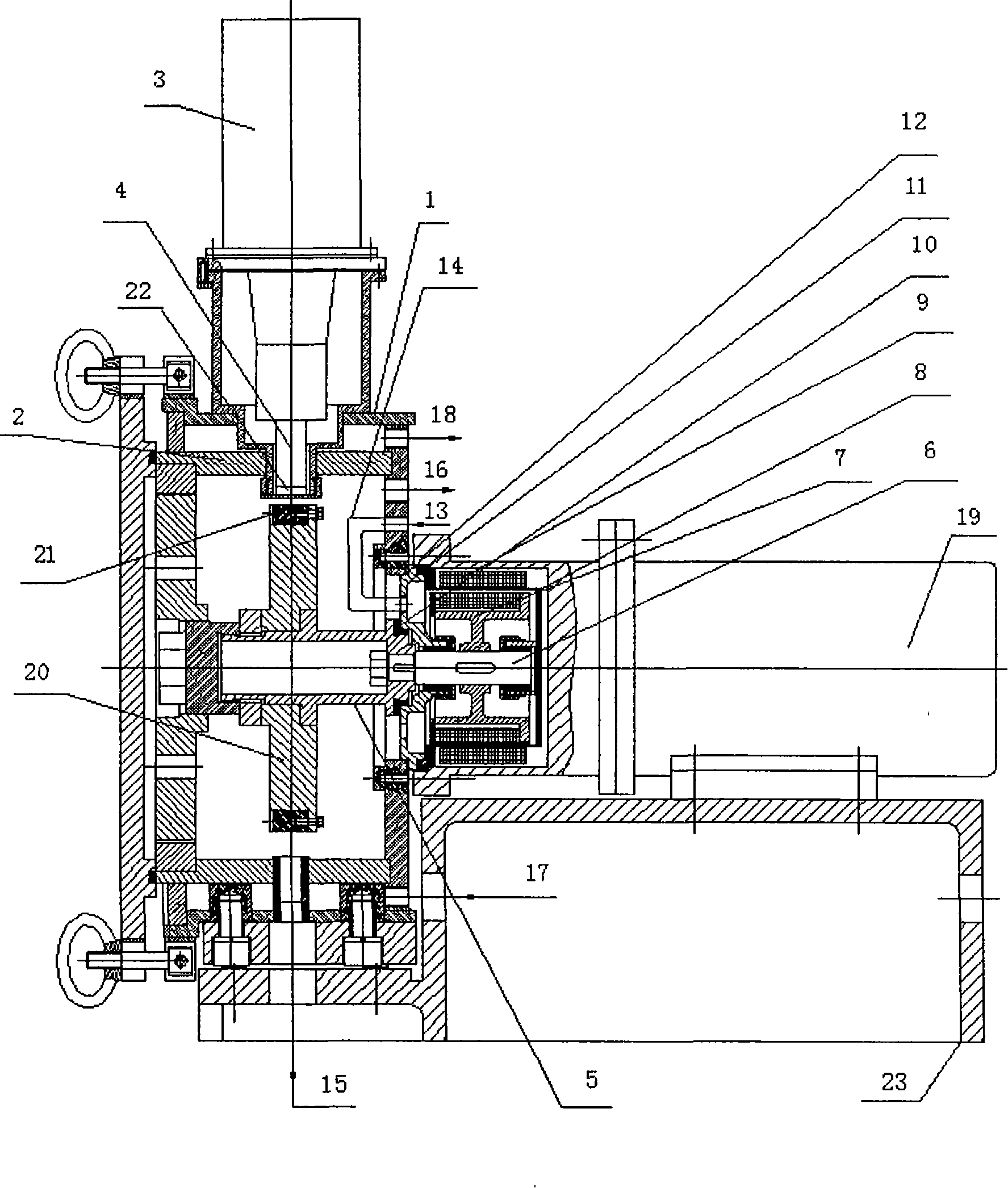

[0019] Place the inner cylinder liner 2 coaxially in the outer steel sleeve 1, the magnetostrictive transducer 3 passes through the outer cylinder liner 1 and the inner cylinder liner 2, and install on the horn 4 at one end of the magnetostrictive transducer 3 The end of the cavitation sample 22 extends into the horizontal water tank. A hollow main shaft 5 is mounted on the horizontal axis of the horizontal water tank. The axis line of the output shaft of the motor 19, the axis line of the main shaft 6 and the axis line of the hollow main shaft 5 coincide with each other. A magnetic outer rotor 9 is installed on the output shaft of the motor 19, a magnetic inner rotor 7 is installed on the main shaft 6, and a horizontal cup-shaped isolation made of a non-magnetic material is used between the magnetic outer rotor 9 and the magnetic inner rotor 7 Sets of 8 separate them from each other. Through the back pressure water inlet 13 and the back pressure water communication pipe 14 o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com