Glow plug with integrated pressure sensor and body thereof

A pressure sensor and spark plug technology, applied in the main field of preheating spark plugs, can solve problems such as high cost and interference measurement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

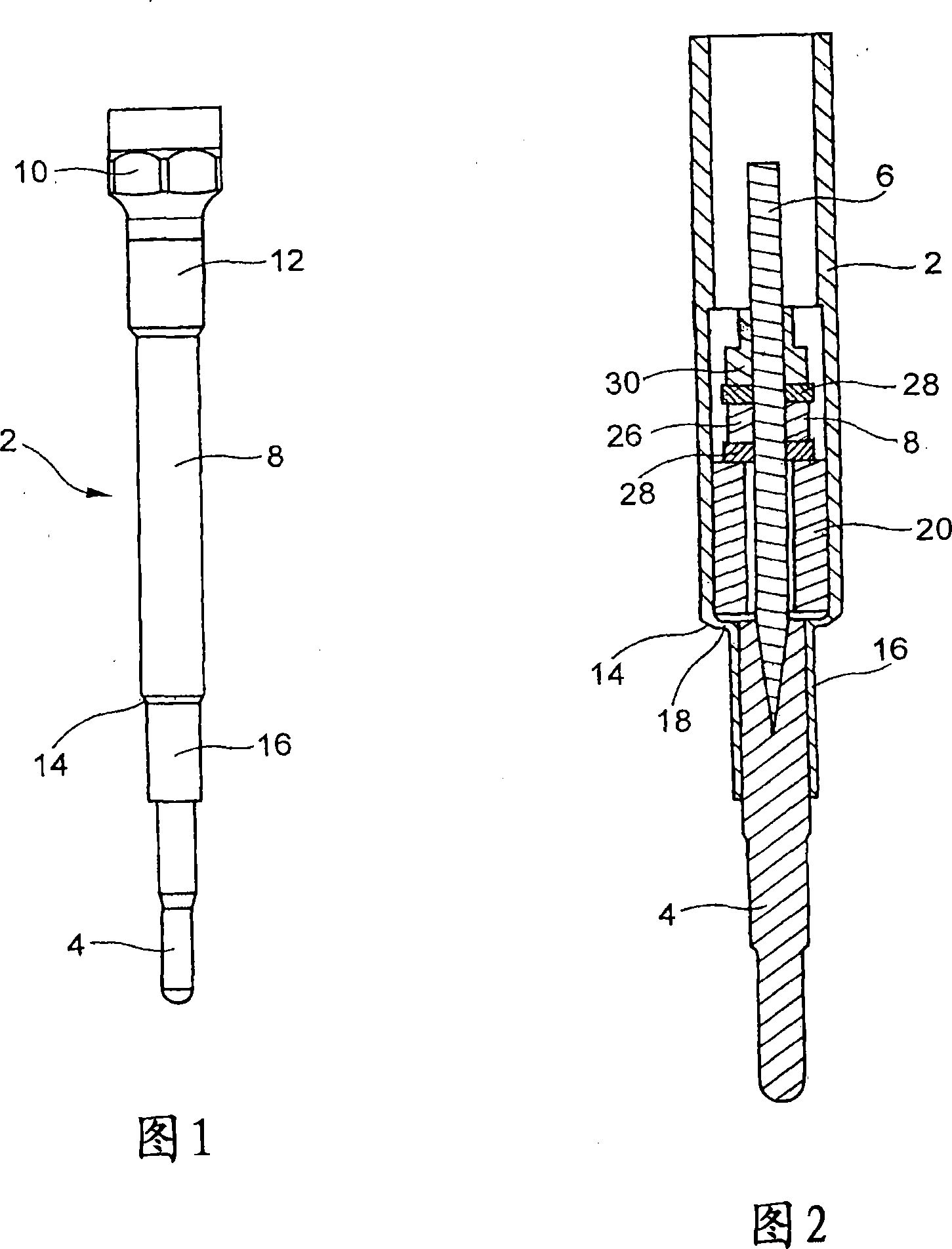

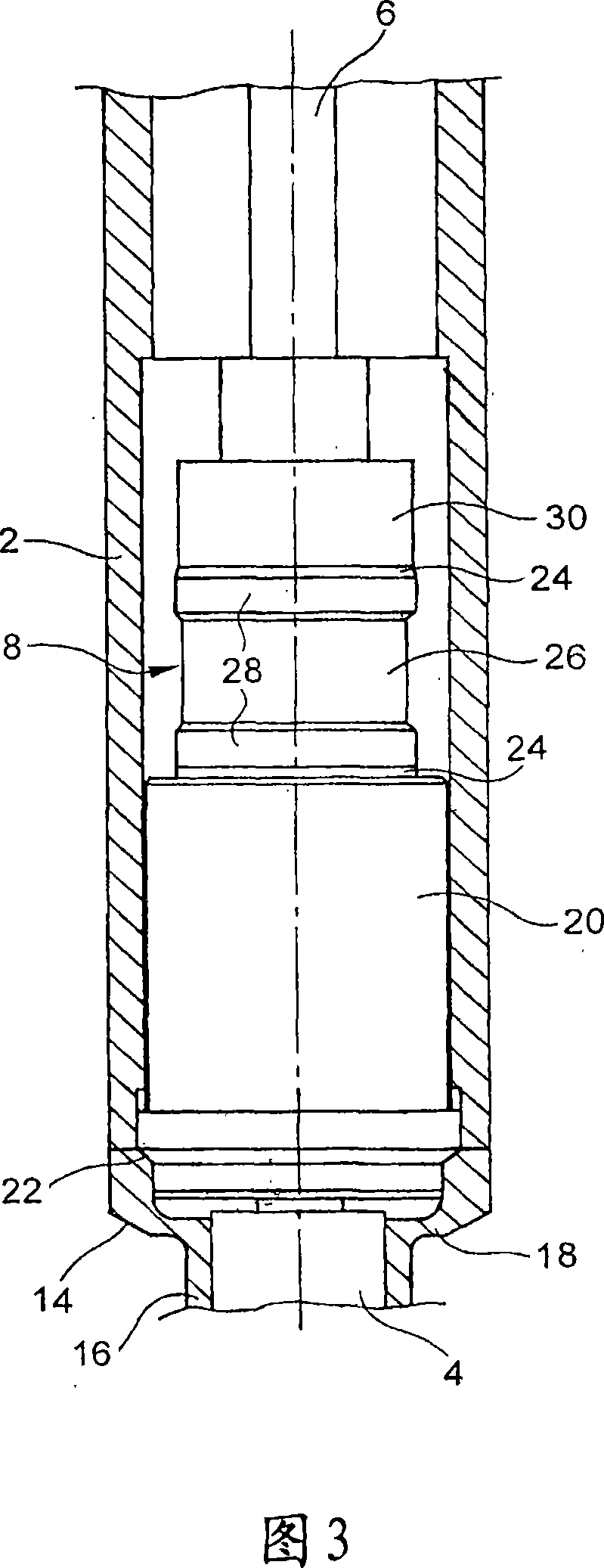

[0027] [27] A glow plug can be seen in Figures 1 and 2, which is known to those skilled in the art and includes a main body 2, a finger body 4, a core (me) 6 and a pressure sensor 8.

[0028] [28] The body 2 is tubular and has a plurality of cylindrical sections. At a first end, referred to as the spark plug tip 10, the spark plug body has a grip area with an outer surface of hexagonal cross-section. This grip area is used to install and remove the glow plugs by tightening / unscrewing them. For mounting, a threaded region 12 is provided adjacent to the spark plug tip 10 . Corresponding threads are provided in the engine cylinder head head to cooperate with the threaded area 12 . In order to improve the sealing between the cylinder head head and the glow plug, it is also conceivable to implement a sealing cone 14 on the main body 2 . This sealing taper 14 will cooperate with a complementary taper surface formed in the cylinder head head and ensure a very good seal between t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com