Printer

A technology for printers and components, applied in the directions of printing devices, printing, winding strips, etc., can solve the problems of inability to print, cannot transport recording paper 13, paper jams, etc., and achieve the effect of excellent reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

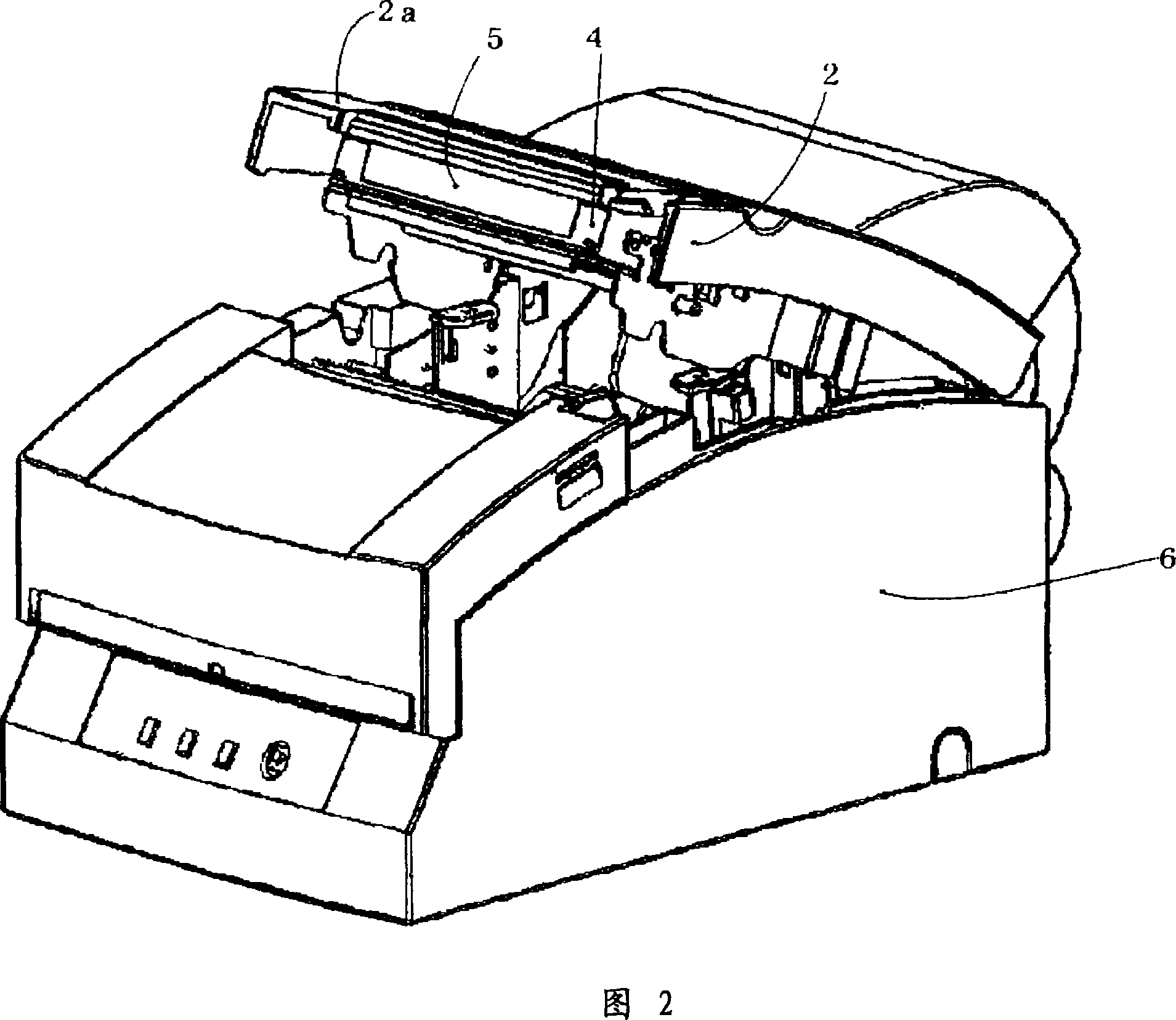

[0024] One embodiment of the printer of the present invention will be described using FIG. 1 and FIG. 2 .

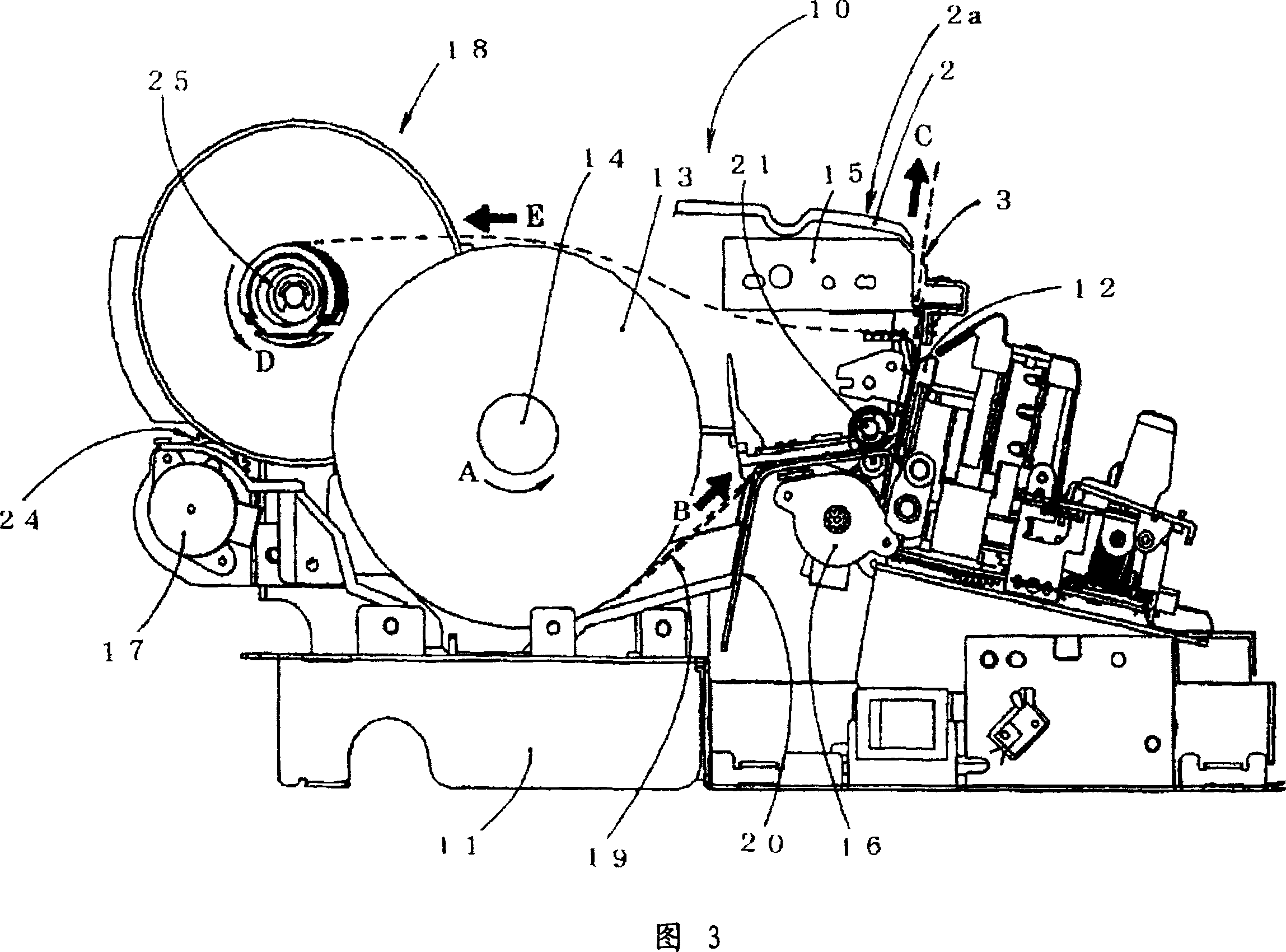

[0025] The basic configuration of the printer is the same as that proposed in the Japanese application described above using FIGS. 3 to 5 , and therefore its description is omitted.

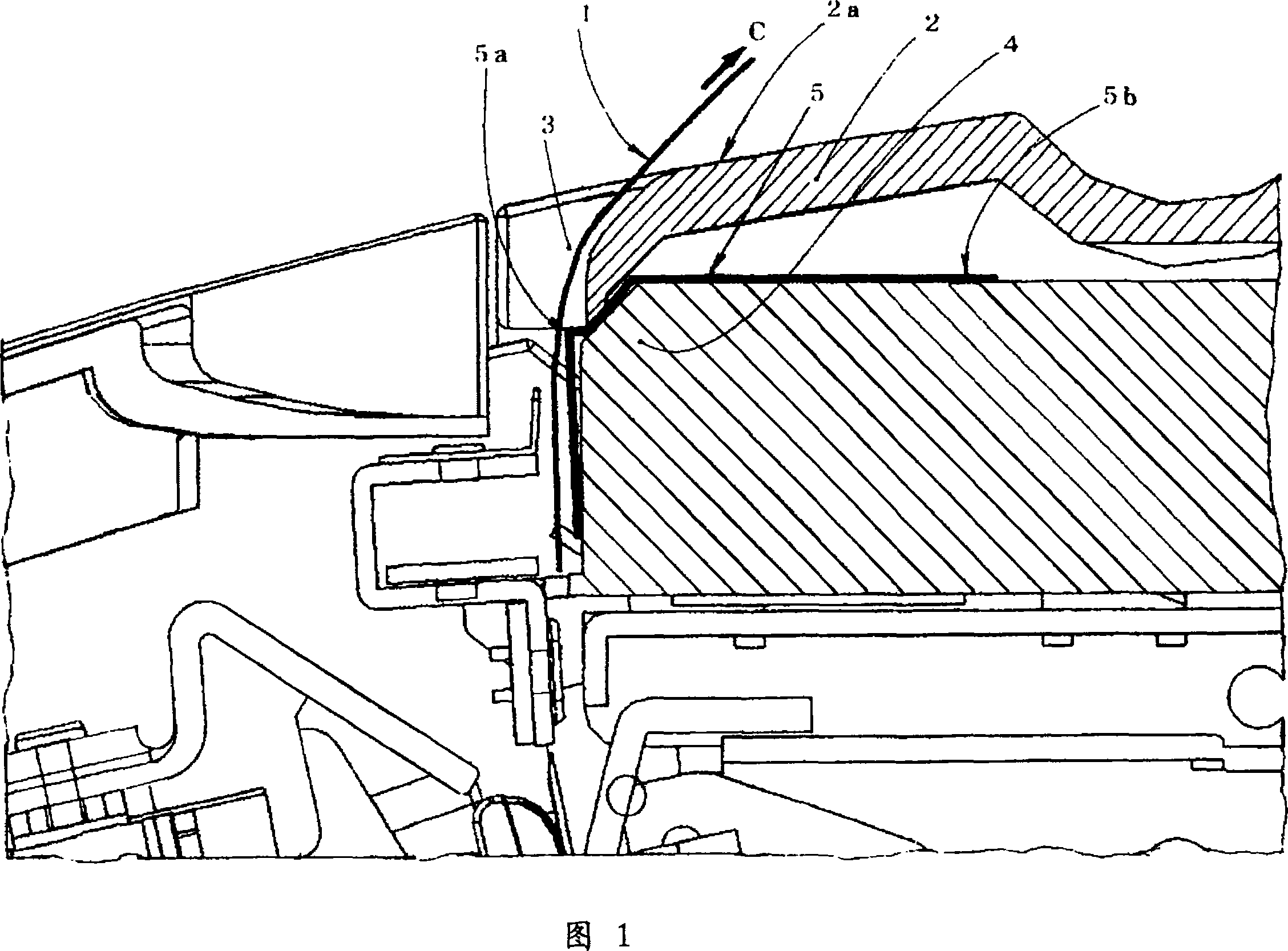

[0026] One sheet of recording paper 1 for a customer on which prescribed items are printed passes through the recording paper path and is discharged from the paper discharge port 3 provided on the end surface of the upper surface 2 a of the outer case 2 . In the vicinity of the paper discharge port 3, the automatic cutter 4, which is arranged upstream of the paper path, and the outer case 2, which is arranged downstream of the paper path, are combined to form a paper path.

[0027] From the gap (corresponding to the gap G in FIG. 4 ) between the automatic cutter 4 and the outer box 2 as a part forming the paper path, two or three places where the plastic sheet or other elongated thin plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com