Self conforming screen

A technology for screens and adaptable materials, which is applied in wellbore/well components, production fluids, earthwork drilling and production, etc. It can solve the problem that the screen has annulus gap, does not want solid output, and can expand the outside of the screen Issues such as limited size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

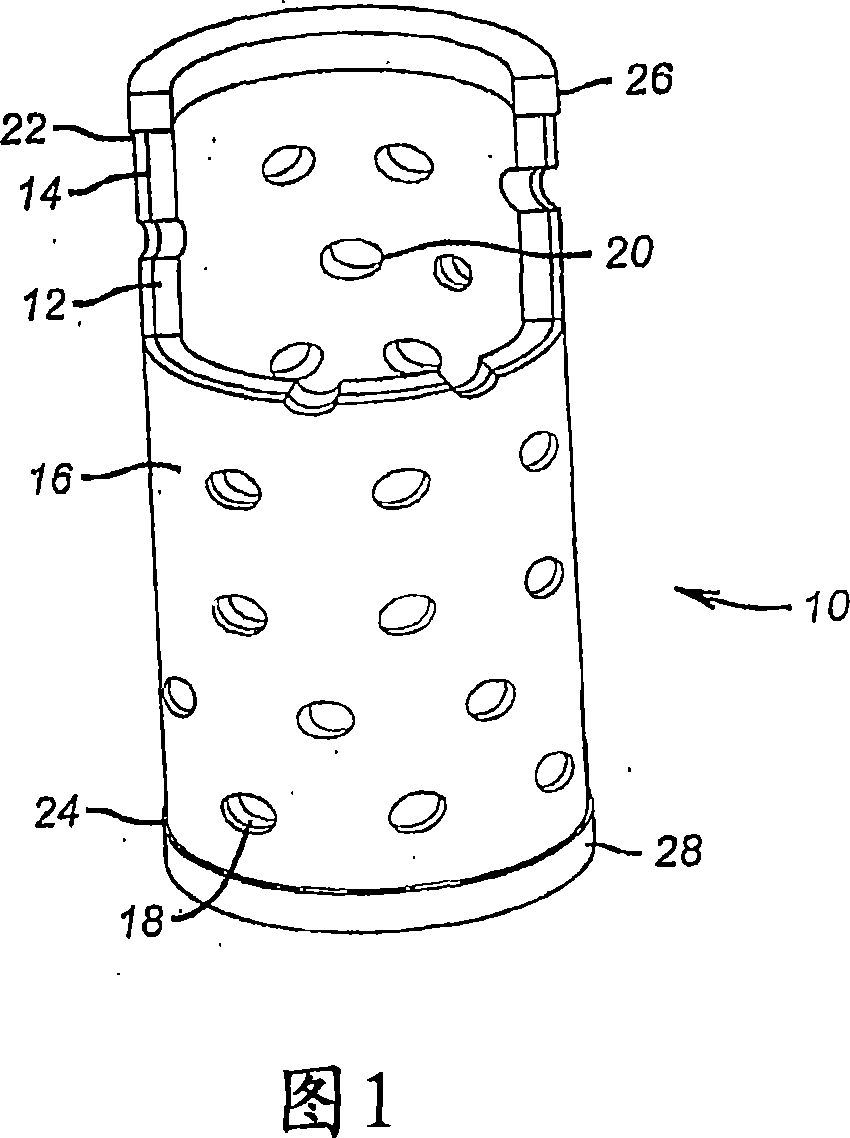

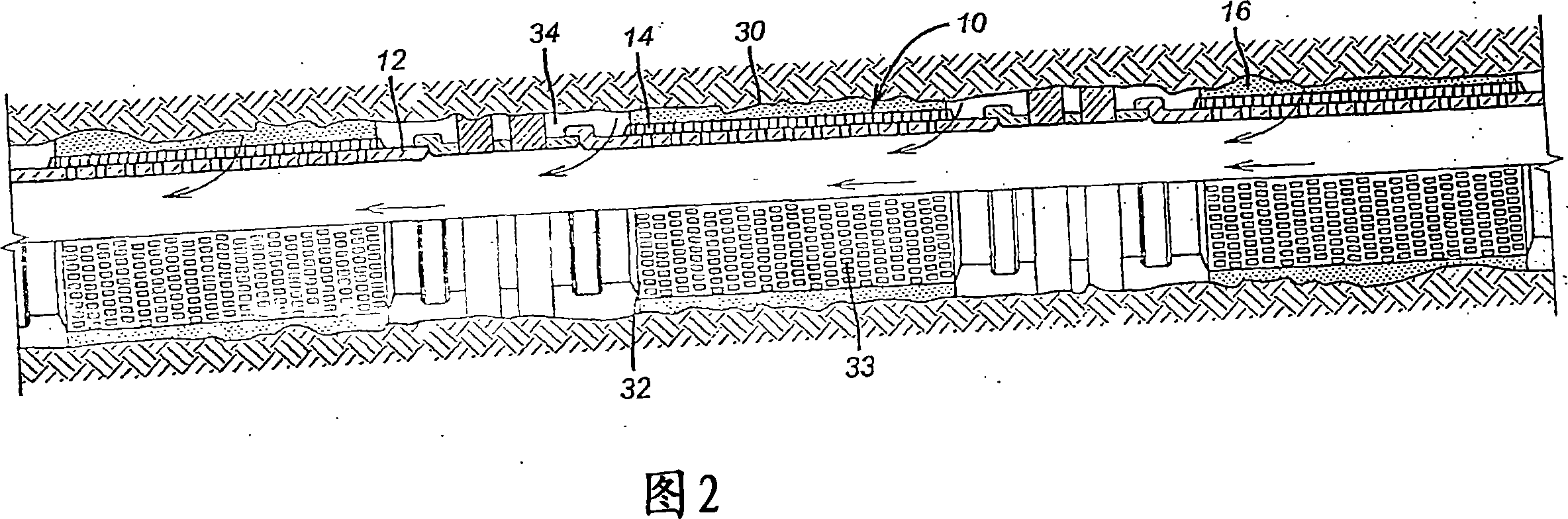

[0011] Figure 1 shows a portion of a length of screen 10 . It has a base pipe 12 above which is a screen 14 above which is an external adaptation layer 16 . Layer 16 has a plurality of holes 18 . The base pipe 12 also has holes 20 . The actual filter material or screen 14 may be a wire mesh or fabric or other known filter products. The conforming layer 16 is preferably soft so that it will flow when the screen 10 expands. Preferred materials are those that swell when exposed to wellbore fluids for an extended period of time. Three examples are nitrile, natural rubber and AFLAS. In an alternative embodiment, the compliant layer 16 expands sufficiently to contact the wellbore after placement in the wellbore without the screen 10 expanding. Shown schematically at ends 22 and 24 of screen 10 are snap rings 26 and 28 . As the screen 10 expands, these stop rings will restrain the compliant layer 16 to prevent longitudinal movement of the compliant layer 16 in the annulus outsi...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap