Turkey seat with memory foam

a memory foam and seat technology, applied in the field of portable seats, can solve the problems of memory foam not being a suitable material for portable products, limited use, and generally not being viewed as memory foam suitable material, etc., and achieve the effects of increasing the viscosity level and density, and reducing the risk of injury

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

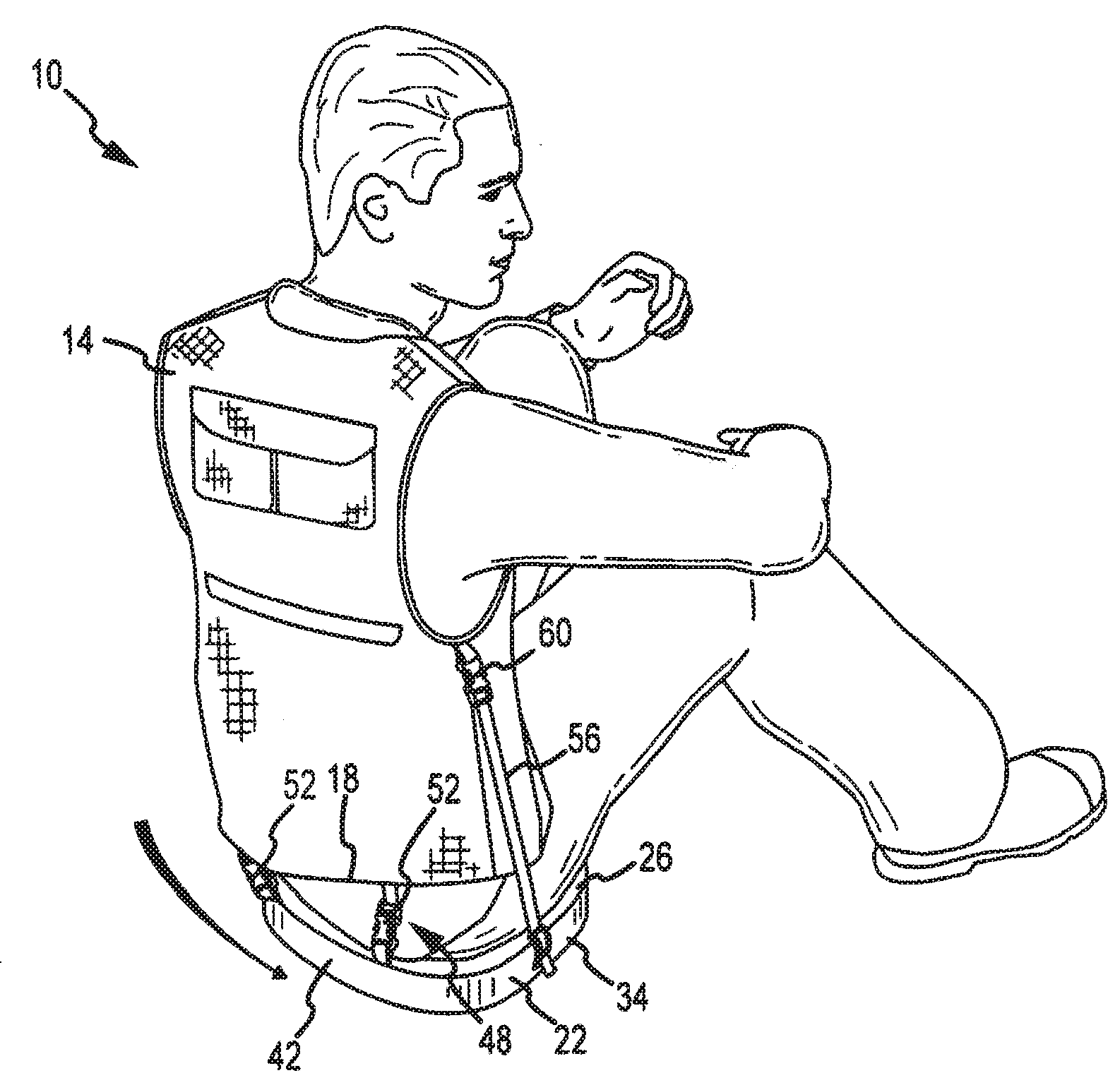

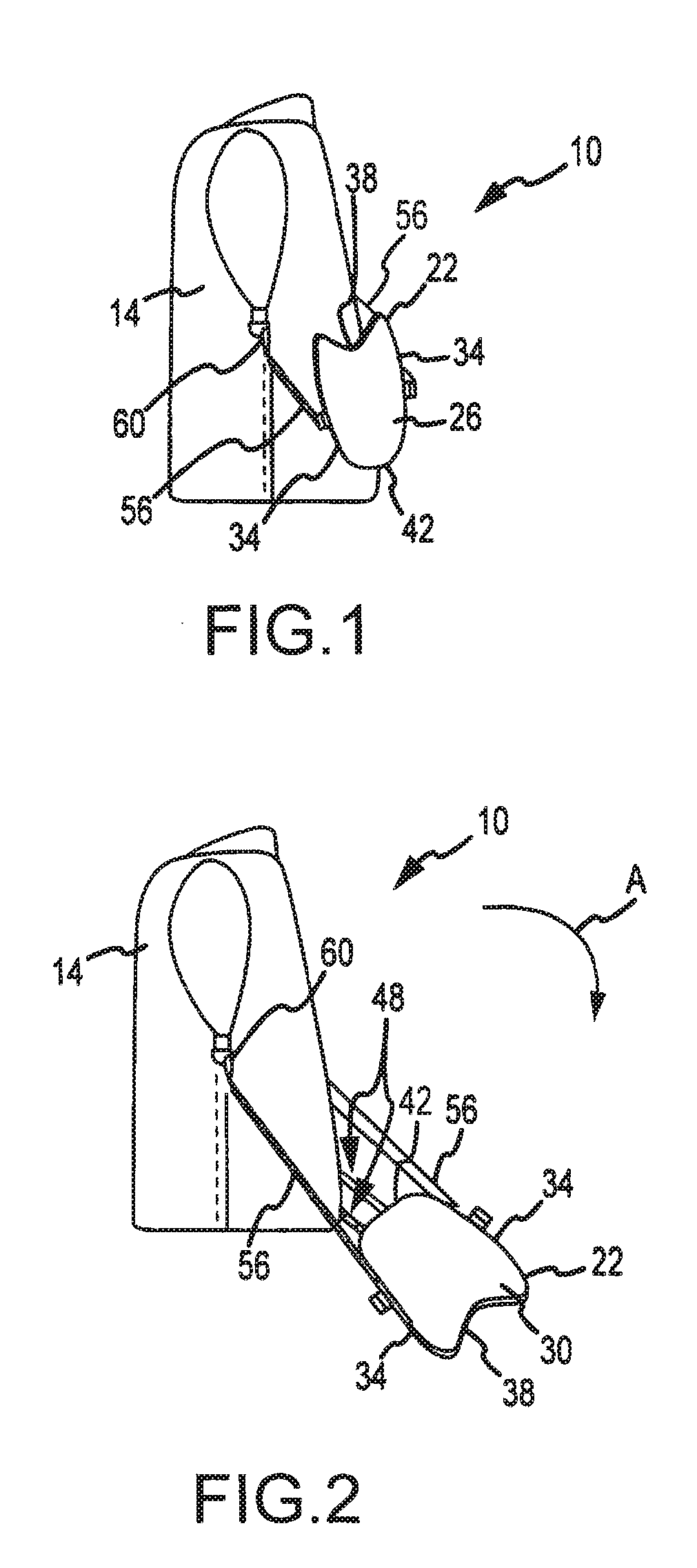

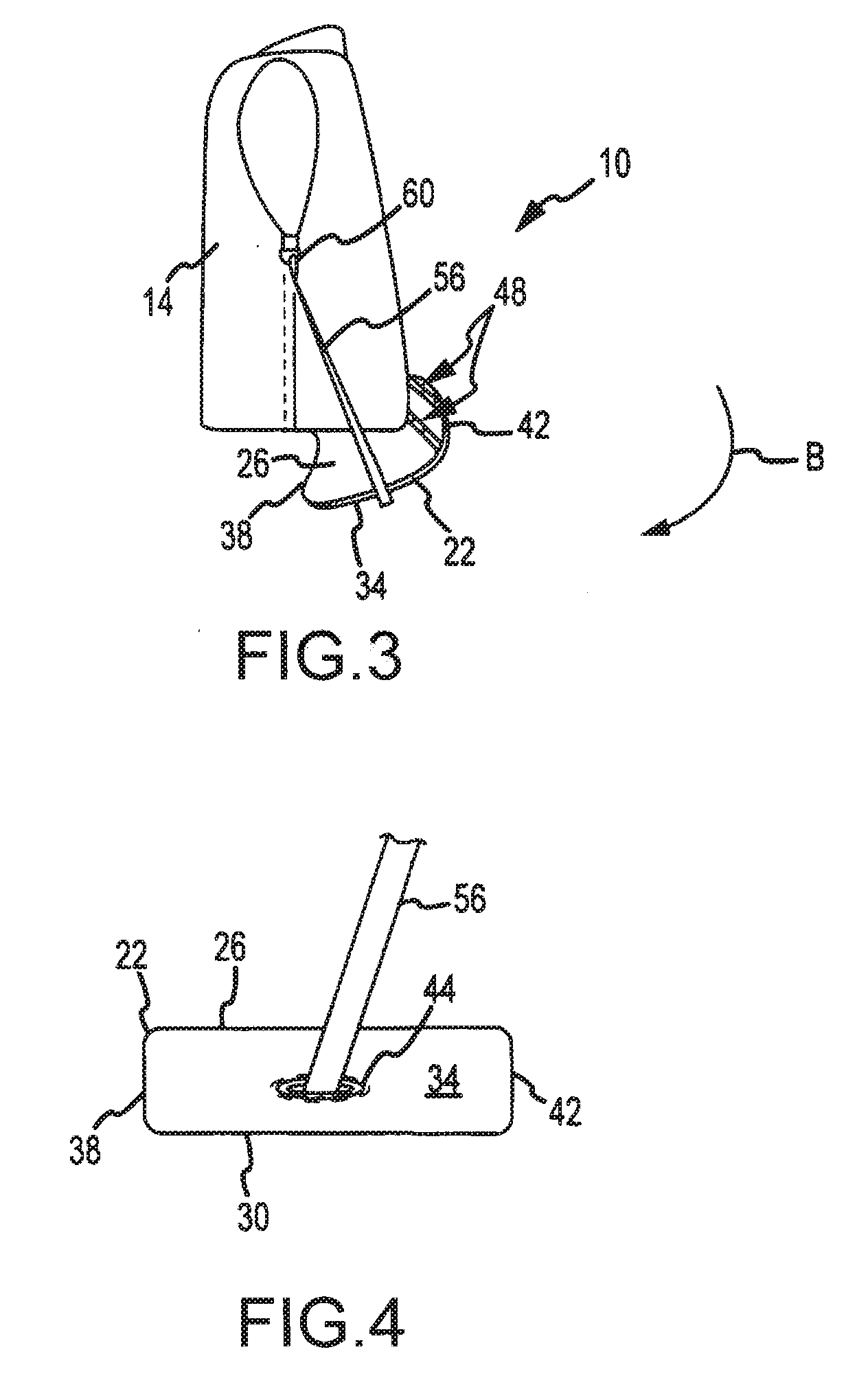

[0023]In the following description, the invention is set forth in the context of a hunting vest with a deployable seat cushion. The deployable seat cushion is formed from multiple layers of material including a memory foam layer. While this is believed to be a particularly advantageous implementation of the invention, it will be appreciated that the invention is not limited to this implementation. The hunting vest garment and seat deployment mechanisms will first be described in the following description. Thereafter, the memory seat cushion structure is described in greater detail.

[0024]One embodiment of a garment assembly is illustrated in FIGS. 1-4 and is identified by reference numeral 10. A perspective view of the assembly 10 is shown in FIG. 8, which further illustrates the seat deployment process. The garment assembly 10 includes a garment 14 and a deployable seat 22. The garment 14 may be of any appropriate size, shape, configuration, and / or type. For instance, the garment 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com