High-power twin-cylinder double flow turbine

A high-power, double-exhaust steam technology, applied to mechanical equipment, engine components, machines/engines, etc., can solve the problems of many materials, uncompact structure, and large footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

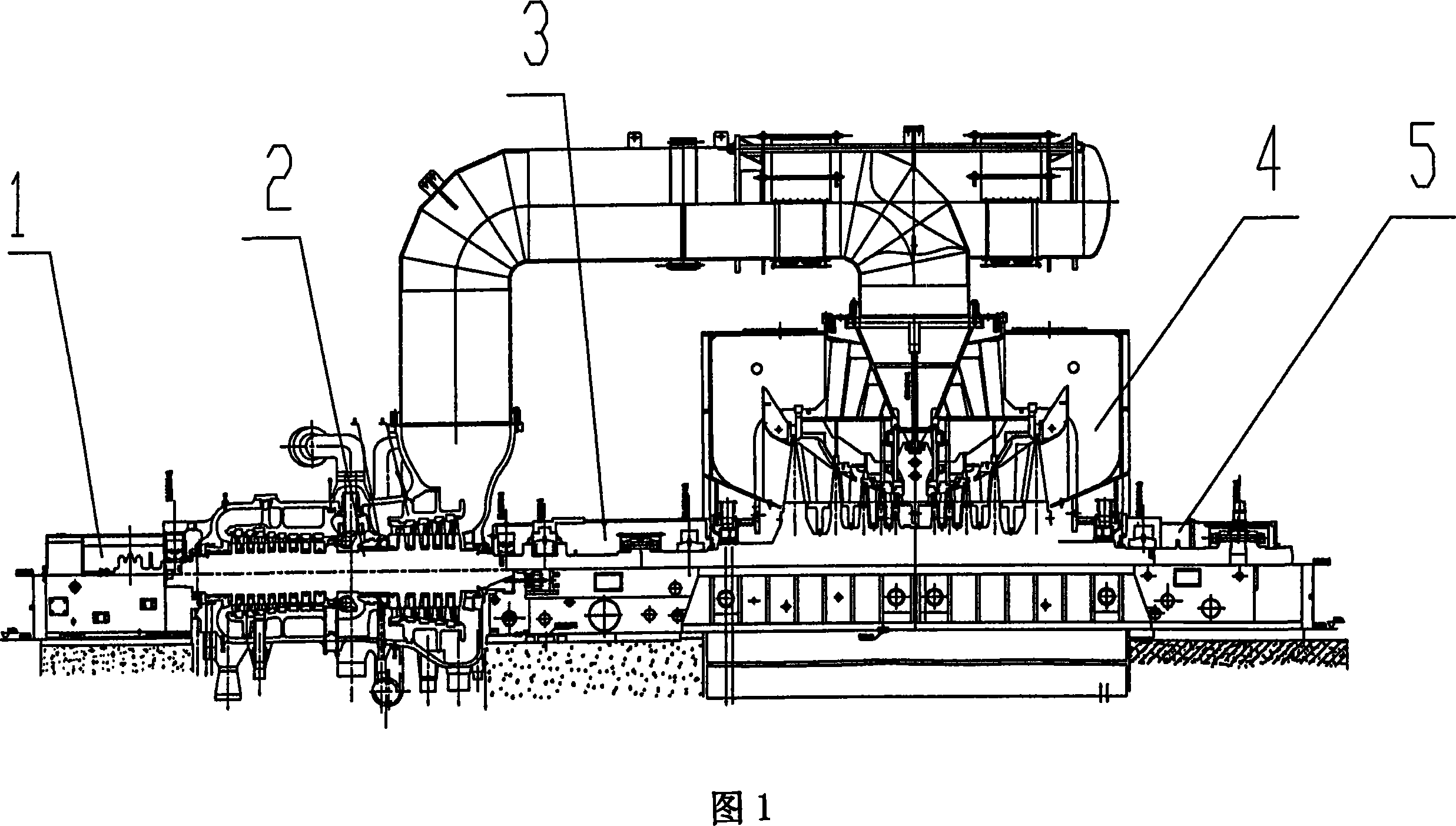

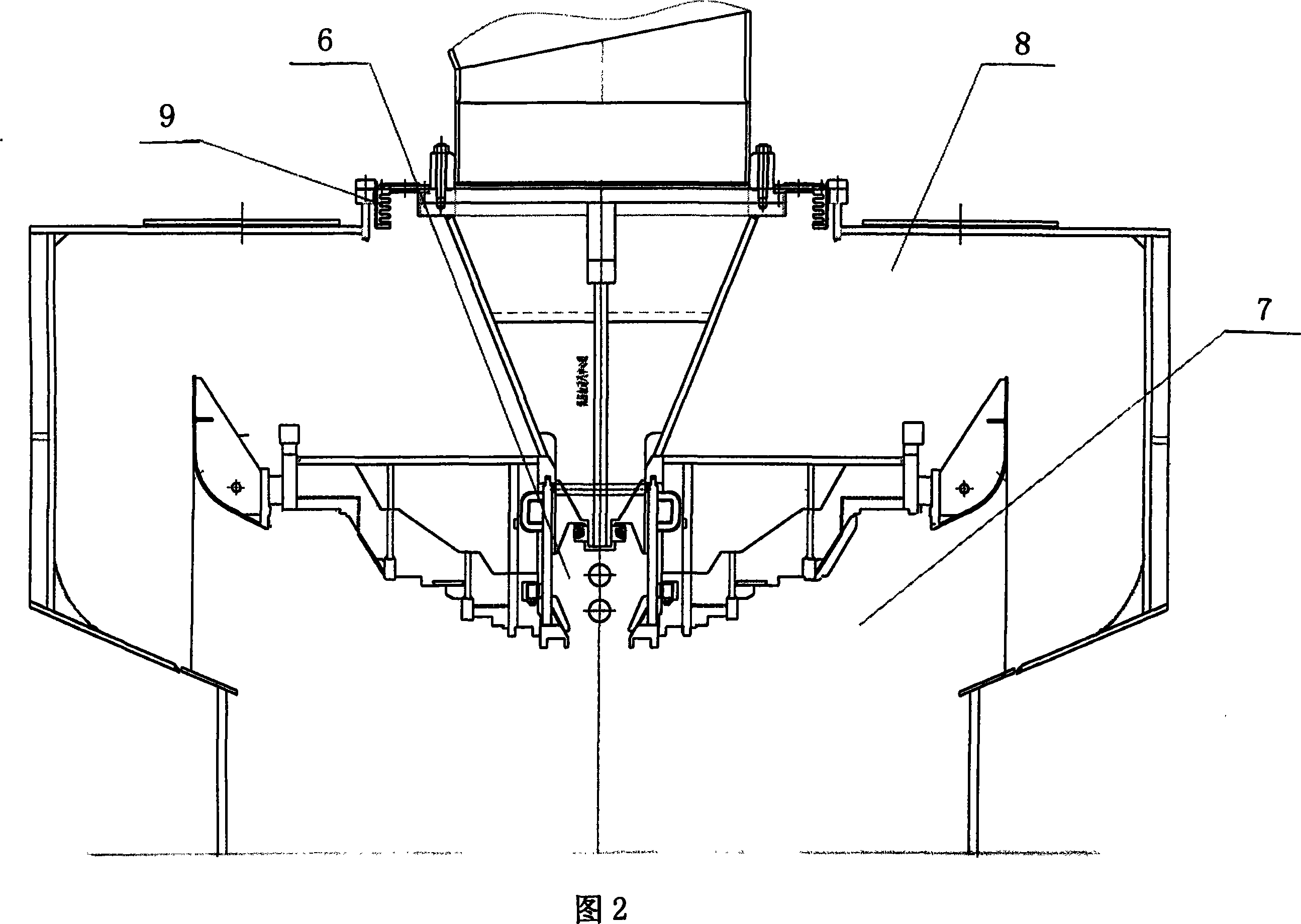

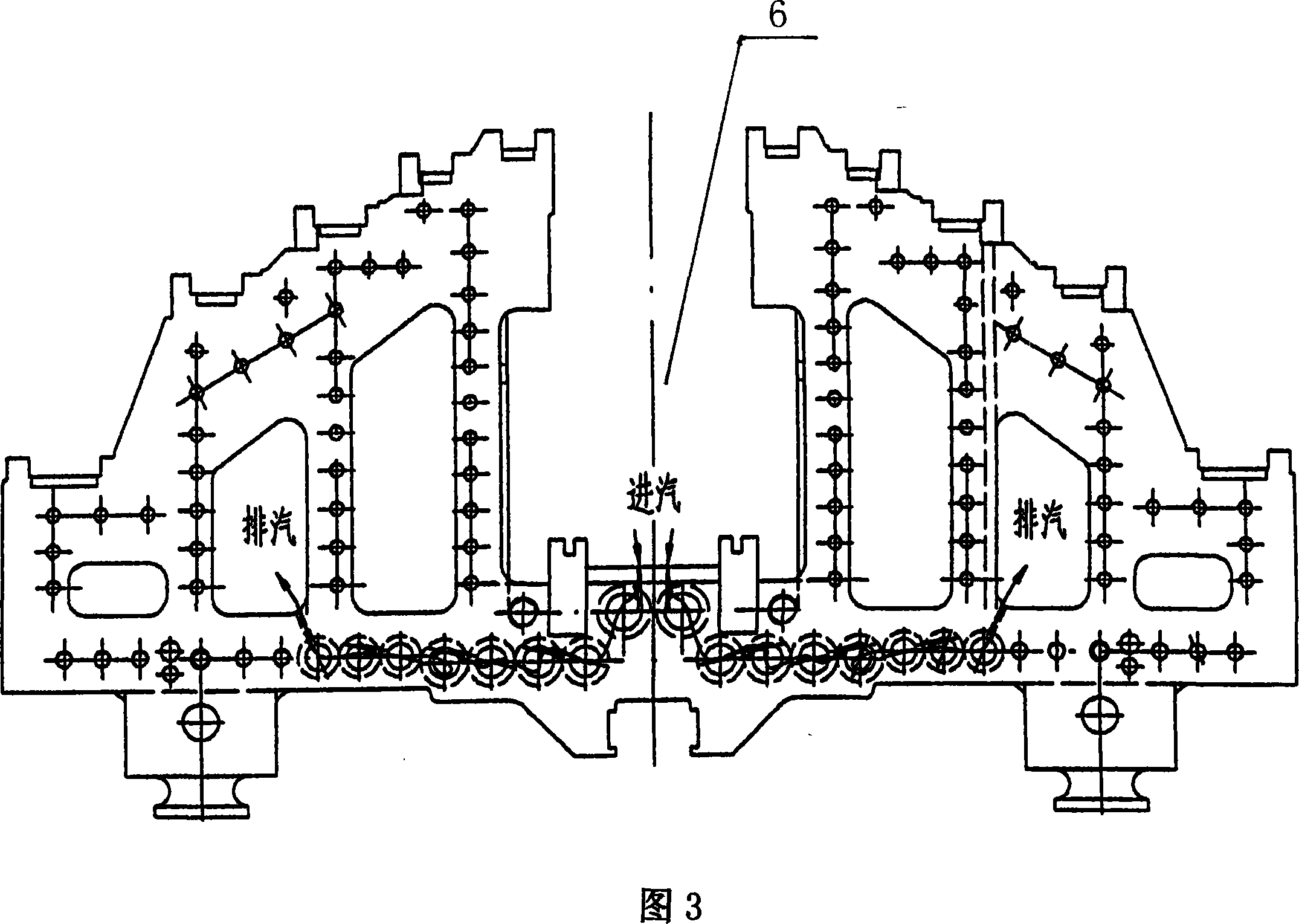

[0023] This machine is a 600MW direct air-cooled steam turbine with high and medium pressure cylinder modules and double-exhaust air-cooled low-pressure modules.

[0024] The main parameters, capacity / capacity are as follows:

[0025] (1) Rated power 600MW

[0026] (2) Unit type Subcritical, intermediate reheat, single-shaft, double-cylinder double-exhaust, direct air-cooled steam turbine

[0027] (3) Rated parameters

[0028] Steam pressure before the high-pressure main steam valve 16.67MPa / 538℃

[0029] Steam pressure before medium pressure main steam valve 3.43MPa / 538℃

[0030] Normal exhaust pressure 0.014MPa

[0031] Exhaust steam pressure (summer working condition) 0.03MPa

[0032] Final feed water temperature 279.5°C

[0033] Main steam flow rate 1875.56t / h

[0034] Unit heat consumption 8178KJ / kw.h (1953.2kcal / kw.h)

[0035] Rated speed 3000r / min

[0036] The total length of the unit is 19.7m

[0037] Direction of rotation Counterclockwise when viewed from th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com