Ink-jet head

A technology of inkjet head and spray head, which is applied in the direction of inking device and printing, etc., and can solve the problems of uneven ejection liquid volume, lower printing quality, retention of air bubbles or impurities, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

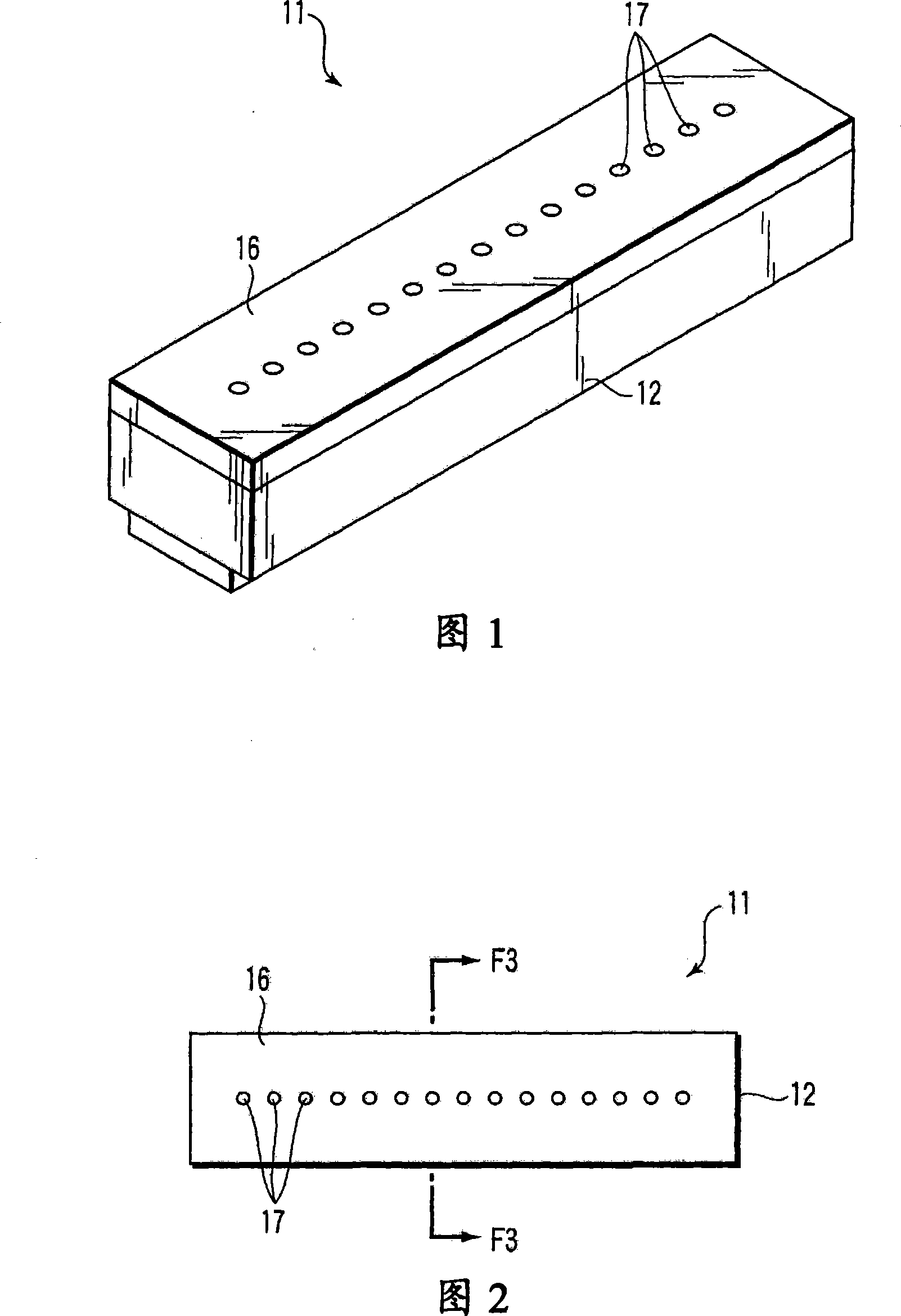

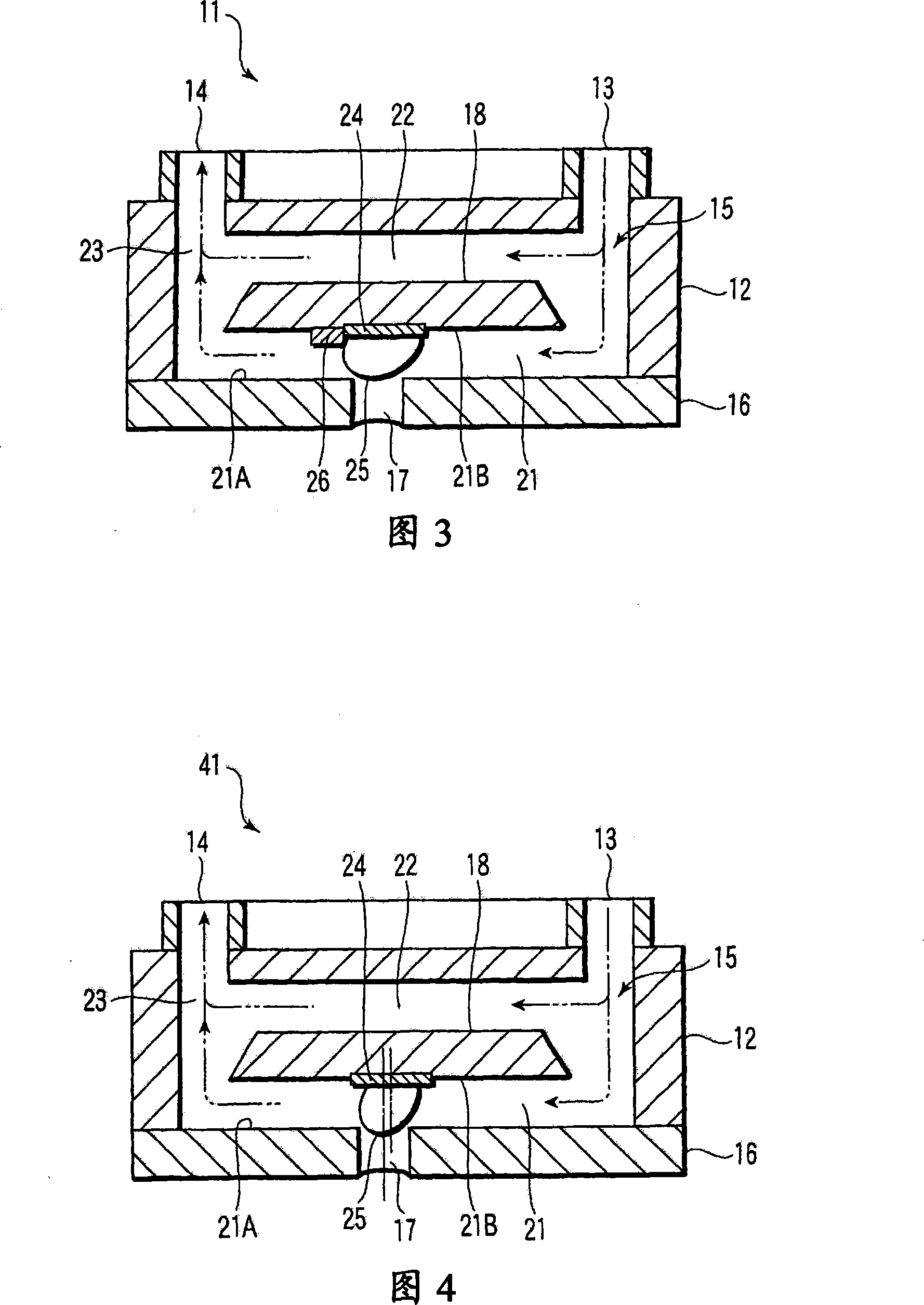

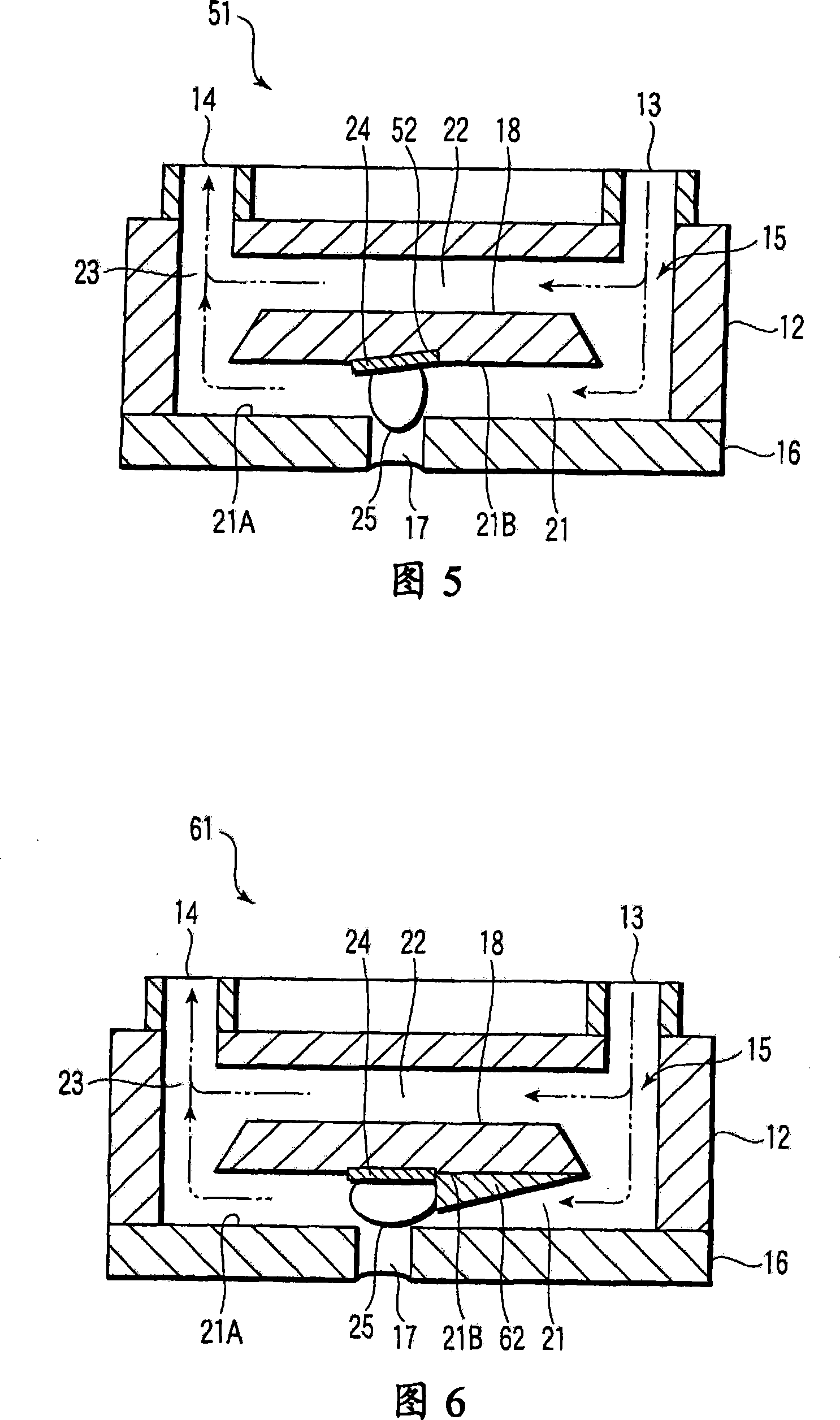

[0015] Next, a first embodiment of the inkjet head will be described with reference to FIGS. 1 to 3 . The inkjet head is mounted on an inkjet recording device, and ejects ink droplets onto a recording medium such as a sheet to form characters, graphics, symbols, and images. The inkjet head is constituted by a so-called ink circulation type head. Hereinafter, the upstream direction refers to the direction toward the inlet, and the downstream direction refers to the direction toward the outlet.

[0016] As shown in Fig. 1, Fig. 2 and Fig. 3, the inkjet head 11 includes: a nozzle body 12; an inflow port 13, which is arranged on the nozzle body 12; an outflow port 14, which is arranged on the nozzle body 12; And an ink flow path 15 formed inside the head main body 12 so as to connect the inflow port 13 and the outflow port 14 . The head body 12 is formed in a square shape. The head body 12 has a nozzle plate 16 on which a plurality of nozzles 17 are formed. The head main body ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com