Drive circuit of LED

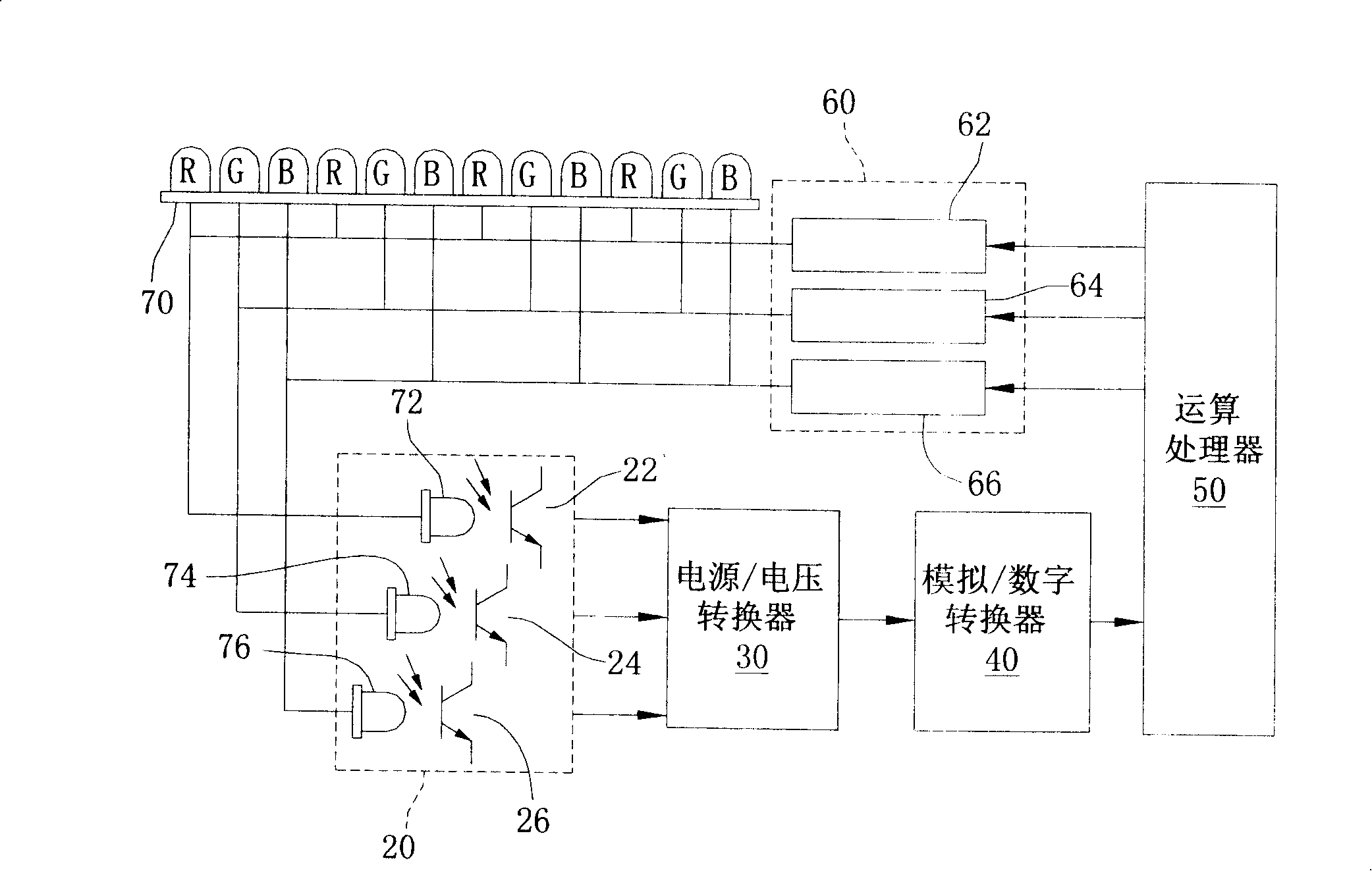

A technology of light-emitting diodes and driving circuits, which is applied in the field of driving circuits, and can solve problems such as excessive forward bias voltage of the LED lamp group 70, adjustment of LED groups due to the inability of the arithmetic processor to judge correctly, and low brightness.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

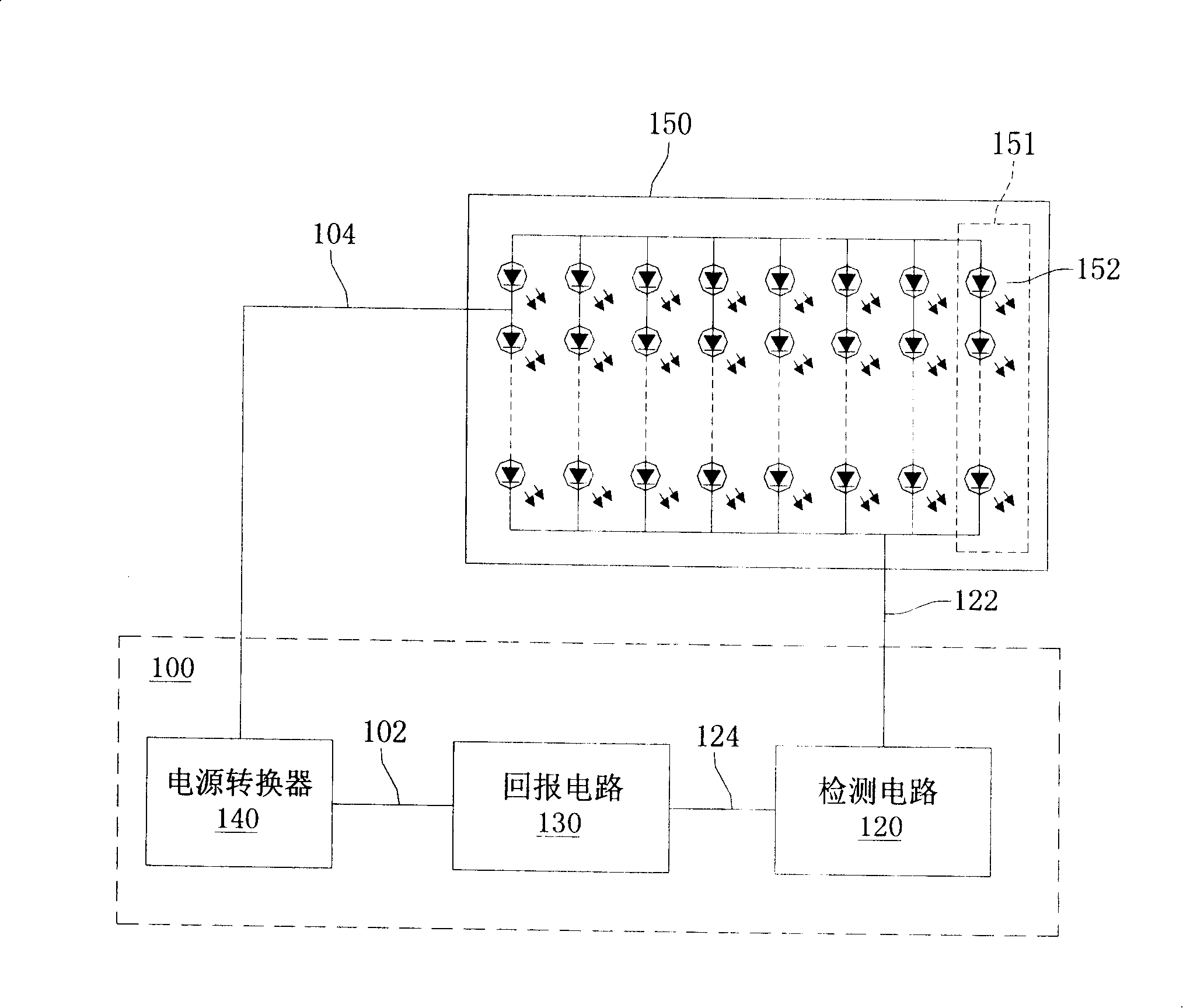

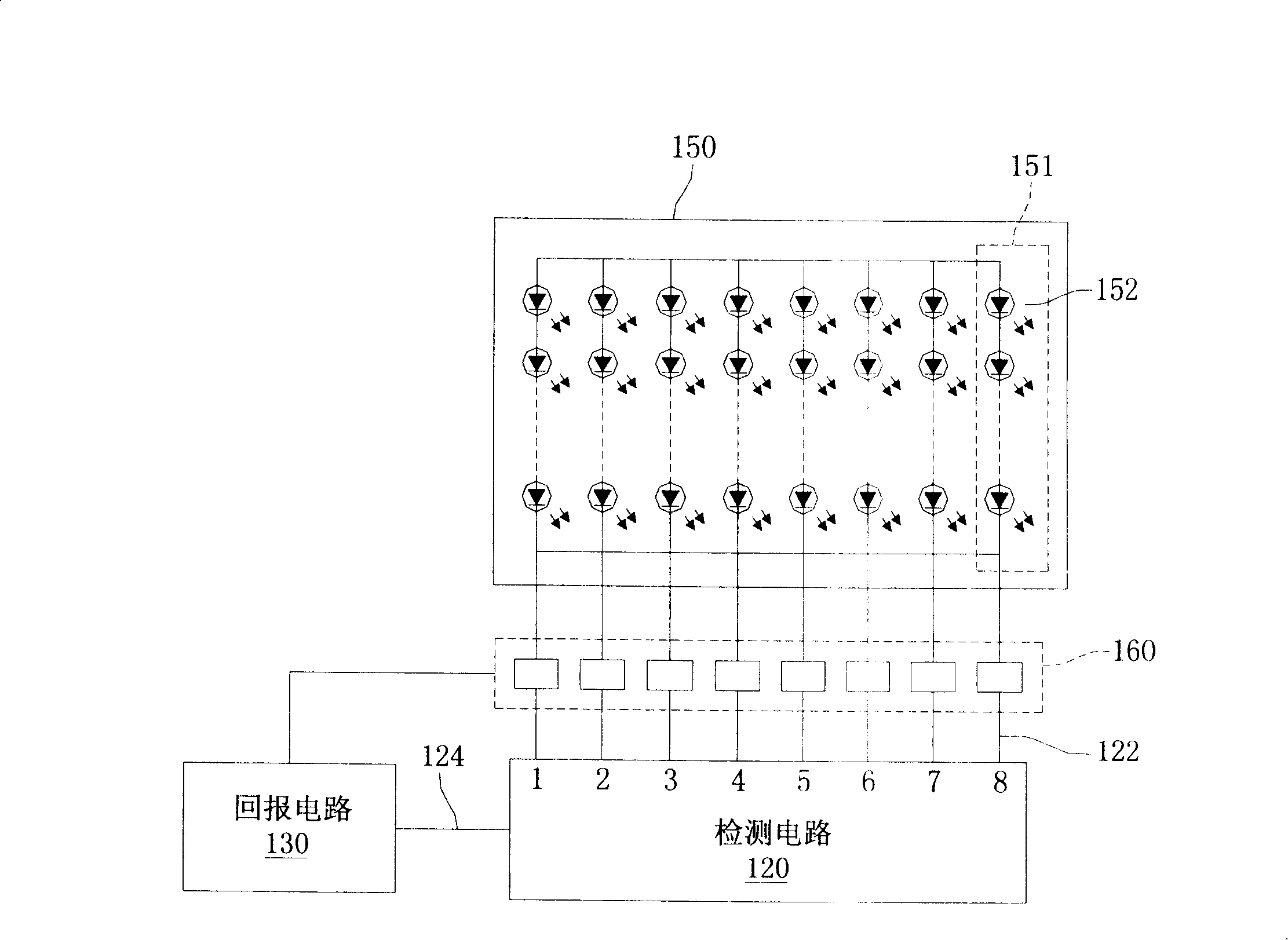

[0041] Please refer to figure 2 , which is a circuit block diagram of the first embodiment of the present invention. It can be seen that the driving circuit 100 of the light emitting diode of the present invention is used to drive a light emitting diode group 150. Diode string 151 constitutes (with eight LED strings 151 forming a LED group 150 in the figure), and each LED string 151 is formed by a plurality of LEDs 152 connected in series, and the drive circuit 100 is driving the LED group 150, it can be driven by providing a constant voltage or constant current, and the driving circuit 100 of the present invention is driven by a constant voltage, and can be driven to emit light all at once, and can also selectively drive a specific LED string 151 to emit light, and By repeatedly driving each LED string 151 sequentially, each LED string 151 can be driven. At the same time, if the switching speed is fast enough, for example, when the switching time is less than 1 / 30 second, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com