Platform and method for adsorbing glass substrate

A glass substrate and platform technology, applied in the field of platforms, can solve problems such as inconvenience for manufacturers, inability to accurately detect the correct position, damage to glass substrates, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The following will clearly illustrate the spirit of the present invention with illustrations and detailed descriptions. After those skilled in the art understand the embodiments of the present invention, they can be changed and modified by the technology taught in the present invention, which does not depart from the present invention. spirit and scope.

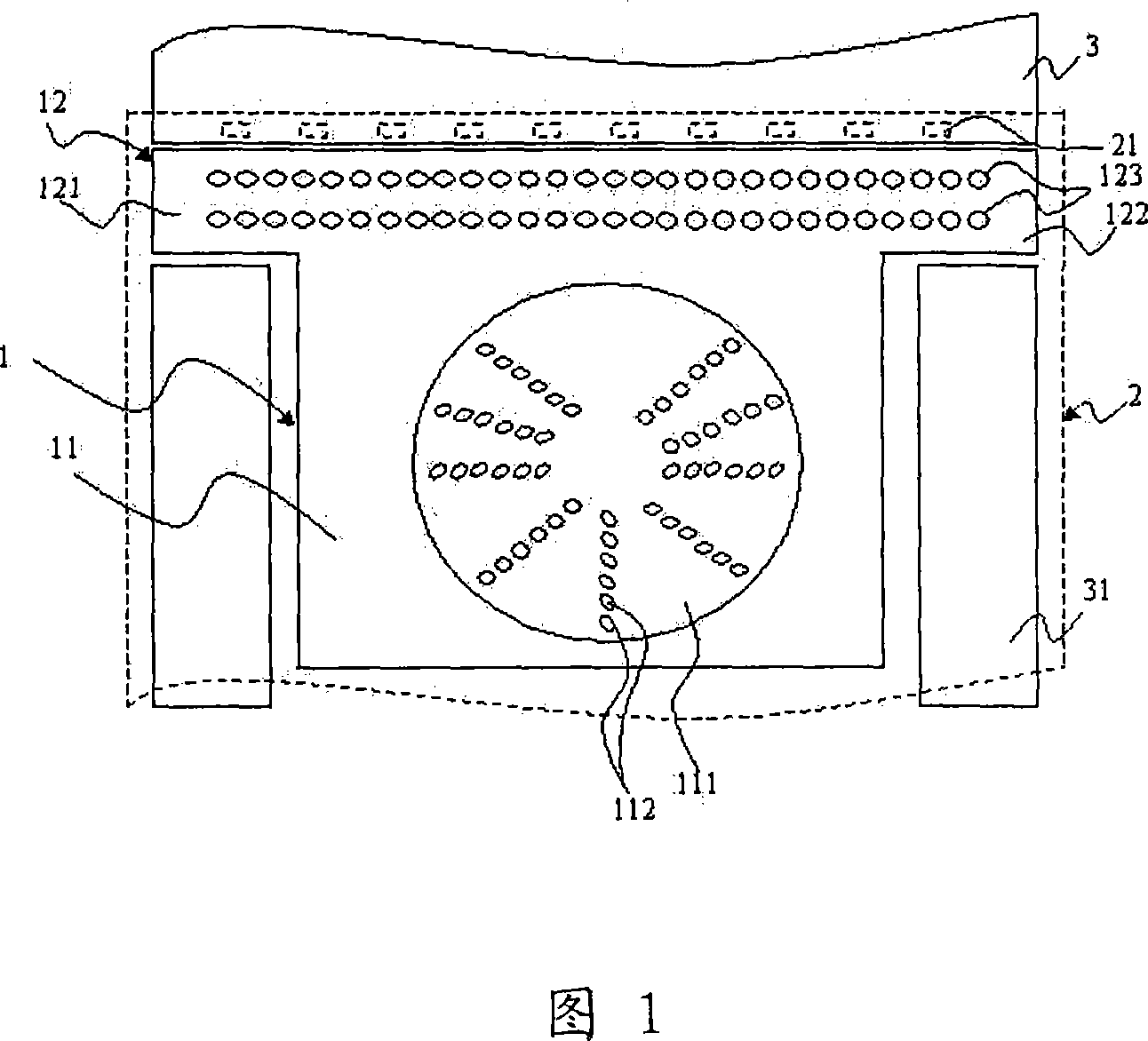

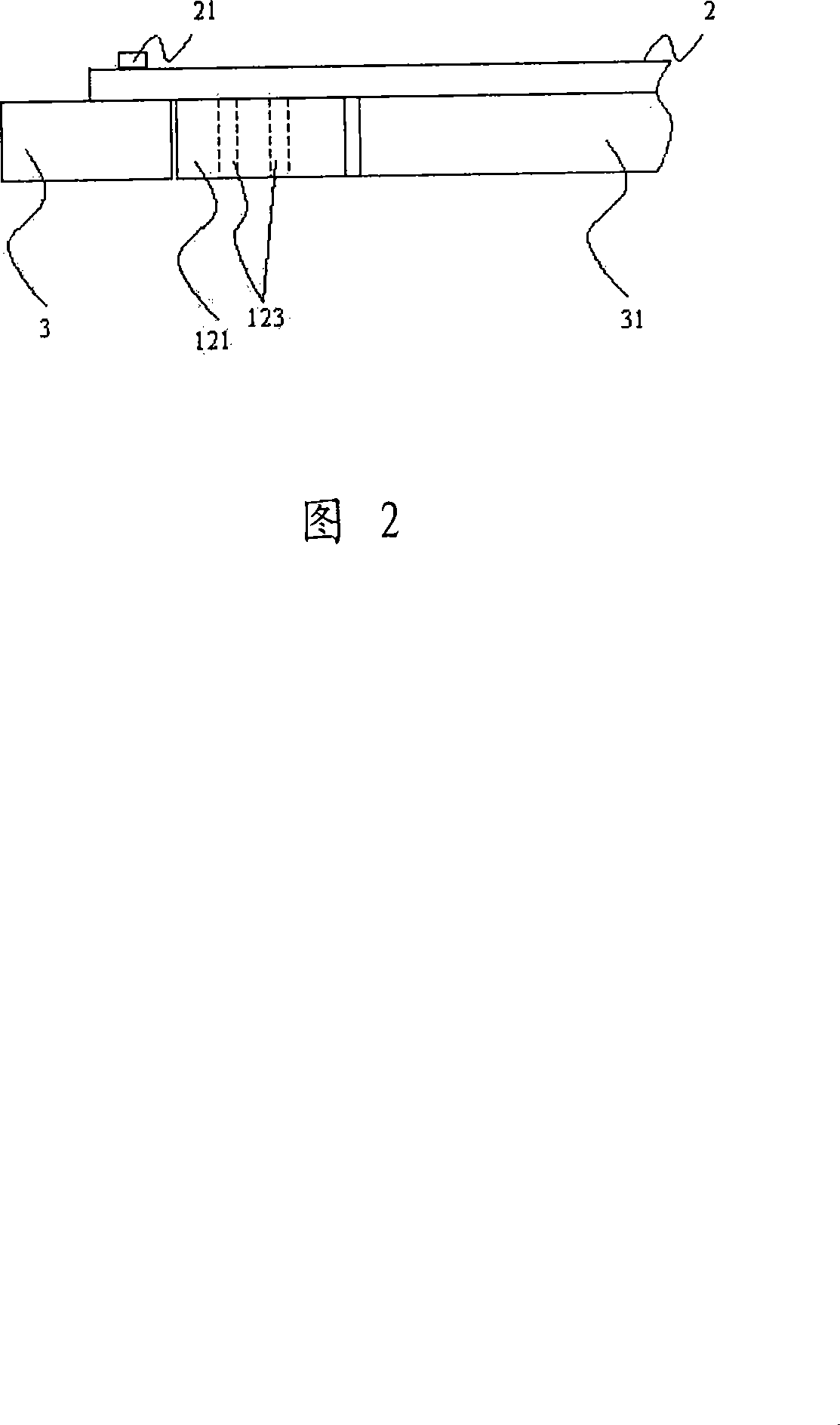

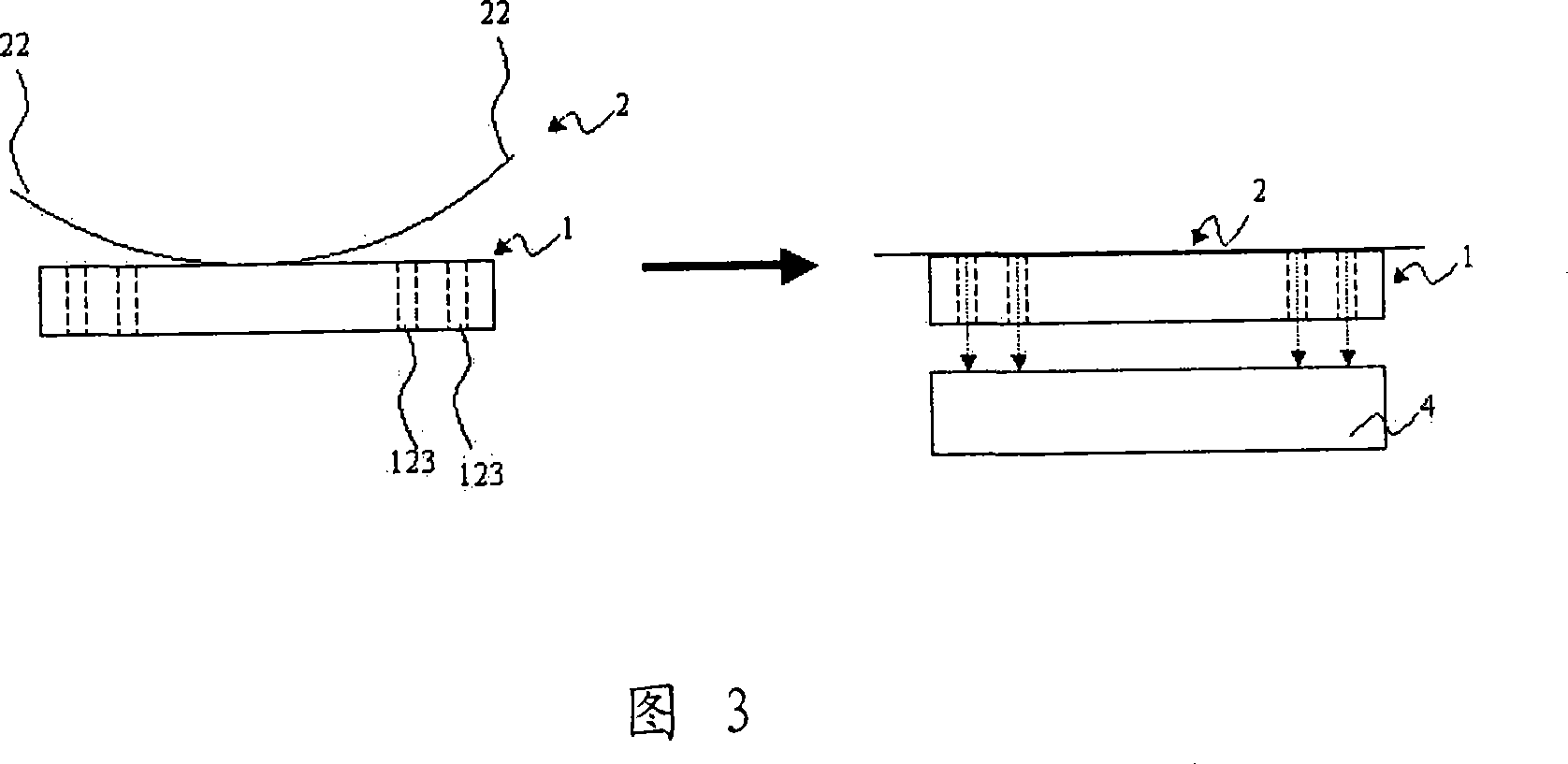

[0027] The present invention discloses a platform for improving the warping phenomenon of glass substrates and a method for absorbing glass substrates, as shown in Fig. 1 and Fig. 2, which are suitable for a production machine of liquid crystal display (LCD). The production machine is used for crimping the drive circuit chip 21 to the edge of a glass substrate 2, and at least includes a platform 1, a mounting area 3 and two moving devices 31. The moving device 31 is, for example, a robot arm. The platform 1 is movable. On one side of the installation area 3, and between the above-mentioned two moving devices 31, it can...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com