Press forming die set and method

A technology of stamping forming and die set, applied in the field of stamping forming, which can solve the problems of increasing the cost of stamping equipment, limited space inside the fixed bead 103, etc., and achieves the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

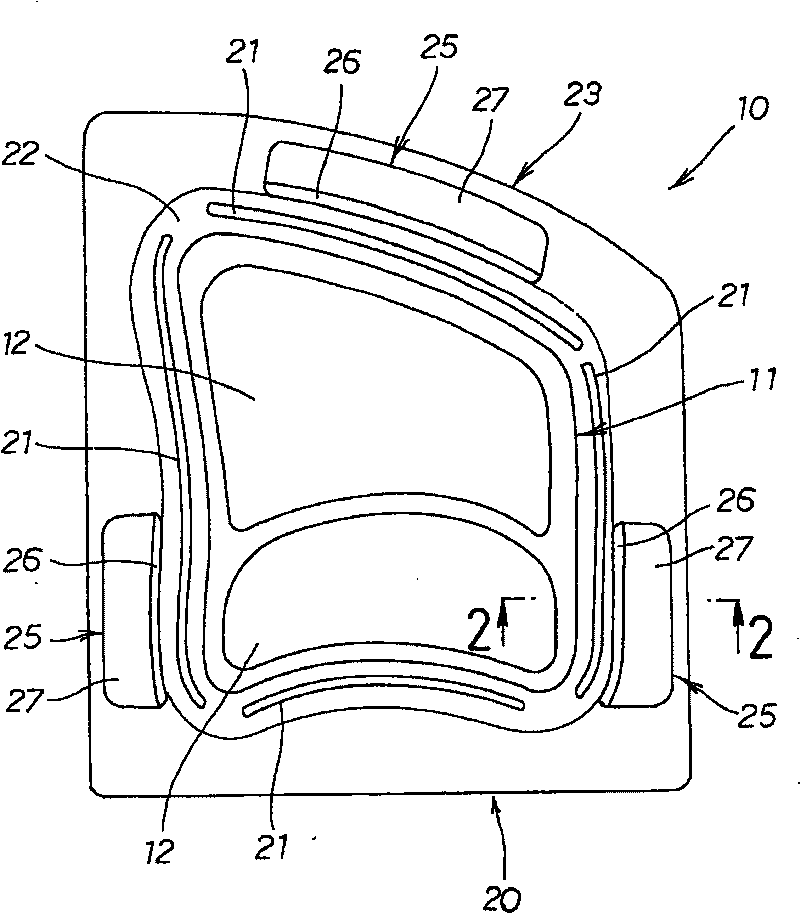

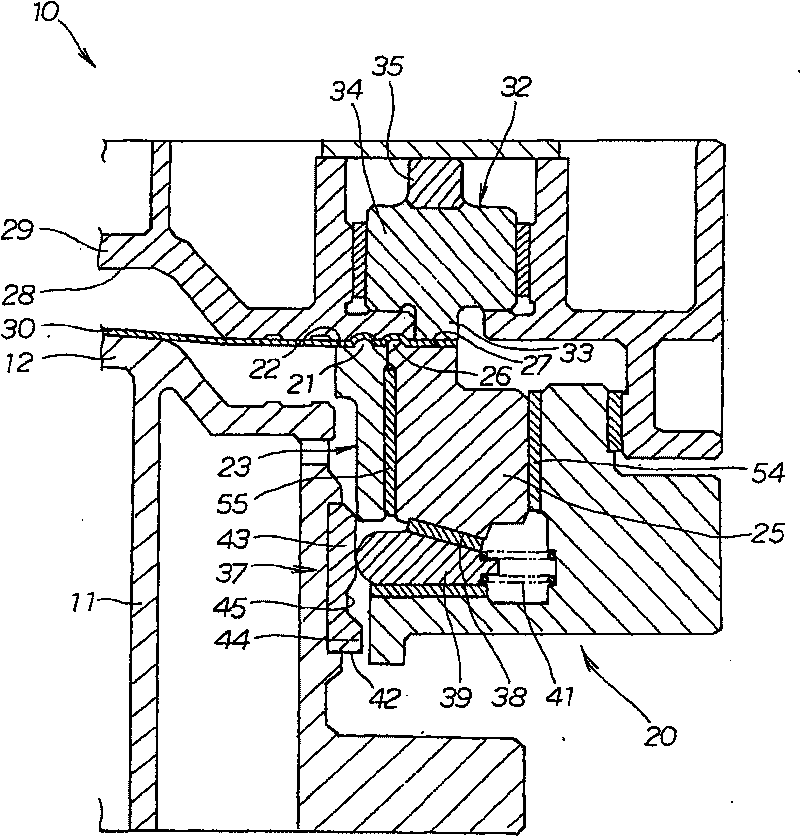

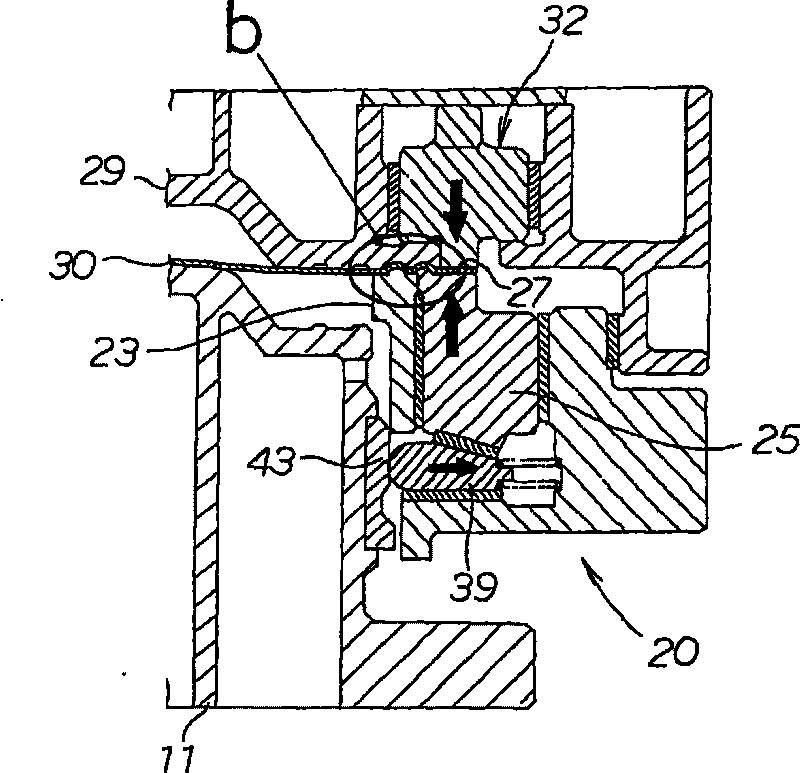

[0031] Such as figure 1 As shown, the punch 11 of the stamping die set 10 is provided with protrusions 12 , 12 . A blank holder 20 is also provided to surround the punch 11 .

[0032] The blank holder 20 is composed of a first blank holder 23 and a second blank holder 25, 25, 25, the first blank holder 23 has a first bead 21, 21, 21, 21 used as a fixed bead Along with the first holder surface 22 which is a mouth-shaped flat surface, the second blank holders 25, 25, 25 are located inside the first blank holder 23 so as to be able to move in the front-back direction in the figure.

[0033] The second blank holder 25 has a second bead 26 serving as a movable bead and a second holder surface 27 which is an I-shaped flat surface. The second bead 26 is arranged closer to the boss 12 than the second retainer surface 27 , ie more inwardly.

[0034] Specifically, the second bead 26 is provided to the edge of the second holder 25 so as to be closer to the convex portion 12 than the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com