Boiler tube expanding head for boiler tube expanding machine

A technology of tube expander and tube expander, applied in the field of tube expander, which can solve the problems of heat exchange tube and tube sheet leakage, poor expansion effect of tube expander, tube sheet corrosion, etc., and achieve a tight seal effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

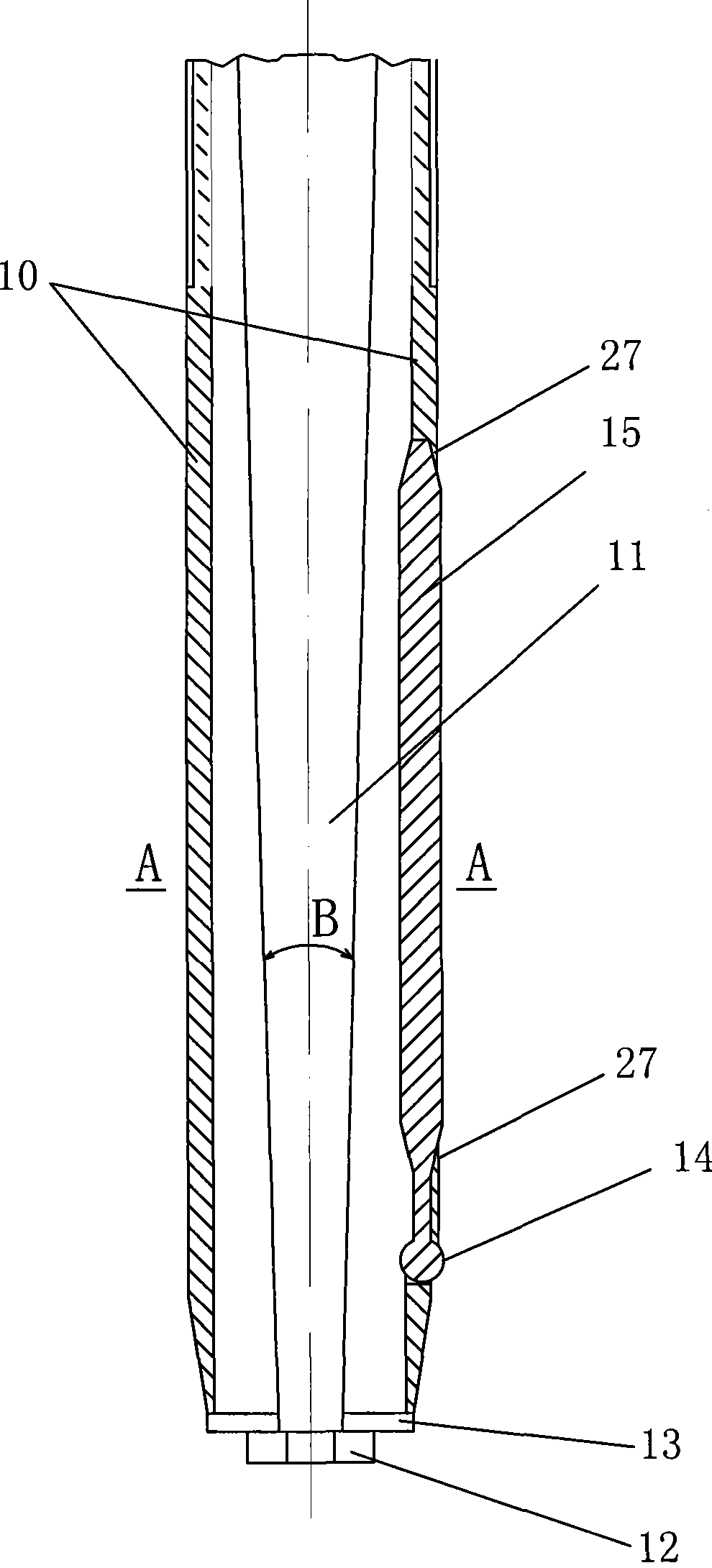

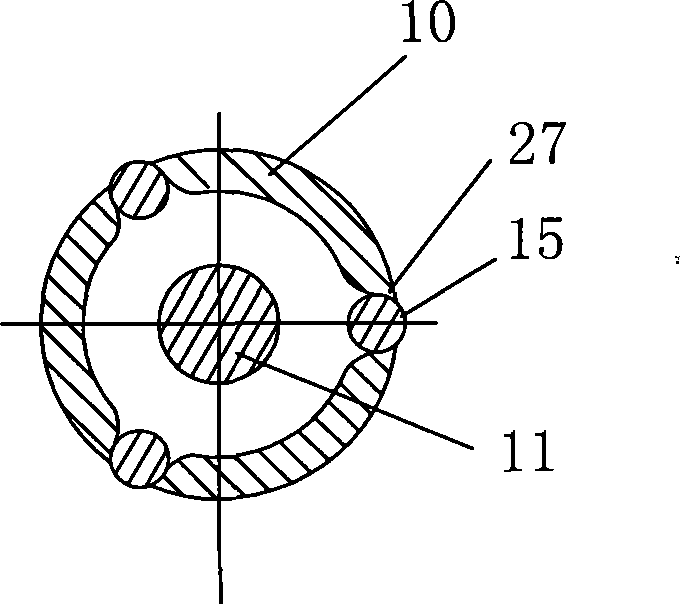

[0016] Embodiment 1: as image 3 , 4 Shown: 10 is a rotating tube, a tapered mandrel 11 is provided on the inner side of the rotating tube 10, three longitudinal long holes are evenly distributed on the circumference of the side wall of the rotating tube 10, and a roller is housed in each long hole. Column 15. The end of the roller 15 is connected with a rolling ball 14. The rolling ball 14 is located in the ball hole on the rotating tube 10. The degree of the cone angle B of the mandrel 11 is controlled between 3° and 5°. The head has a baffle plate 13 that is sleeved on the mandrel 11 and is connected by bolts 12 . The outer edge of the long hole on the rotating tube 10 is provided with a rib 27, which can prevent the roller 15 from falling off outwards.

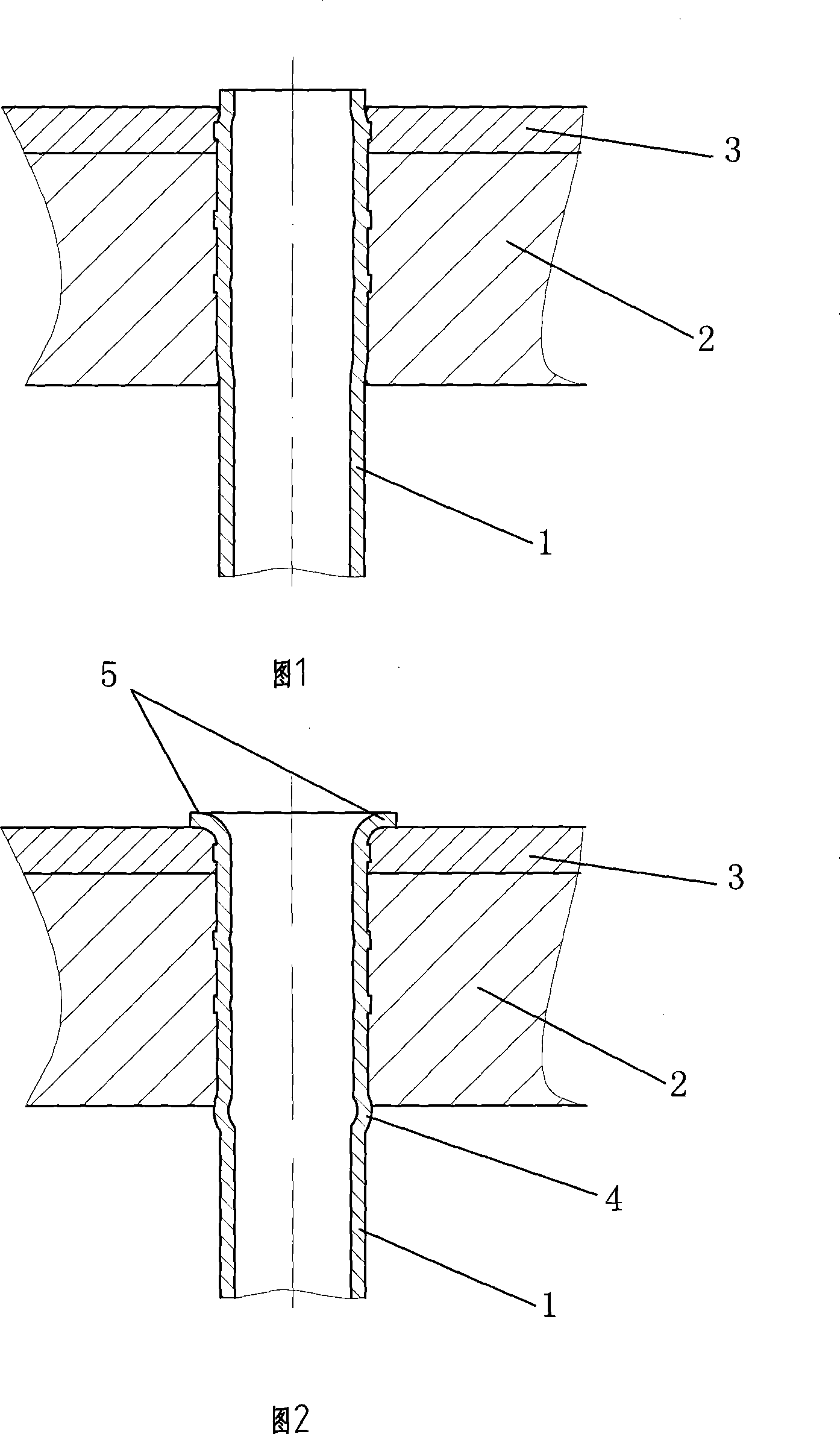

[0017] Such as Figure 7 , 2: when in use, the mandrel 11 and the rotating tube 10 are connected to the hydraulic tube expander 23, driven by the power supply unit 24 and the hydraulic drive unit 22, and the tube expans...

Embodiment 2

[0018] Embodiment 2: as Figure 5 , 6 Shown: The difference from Example 1 is that the end of the rotating tube 10 is connected with a tapered tube 16, and the three rollers 15 and the long holes for loading the rollers 15 are evenly distributed on the tapered surface of the tapered tube 16, and the tapered tube The degree of taper angle A of 16 is controlled between 50°~70°, and the end of mandrel 11 is conical, and its taper angle is consistent with the degree of taper angle A of tapered tube 16 . The device can be used to flang the heat exchange tube 1, so that the port of the heat exchange tube 1 is turned outward to form a flanging 5 (see Figure 2), so that the heat exchange tube 1, the tube plate 2 and the liner plate 3 are more secure and seal.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com