Method for controlling a linear motor for driving a striking mechanism

A technology of impact device and linear motor, which is applied in the direction of electromechanical devices, portable impact tools, electrical components, etc., and can solve problems such as inapplicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

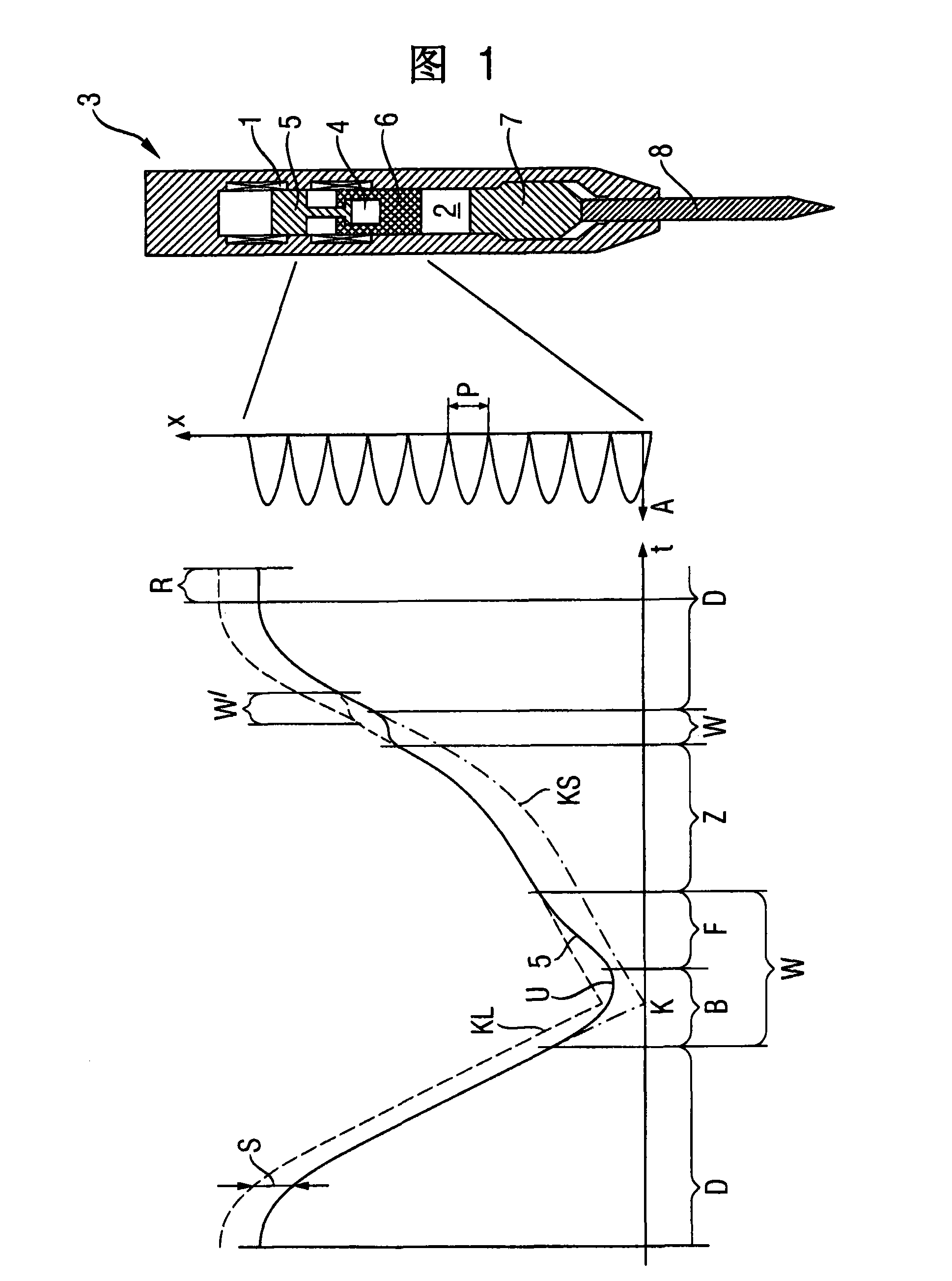

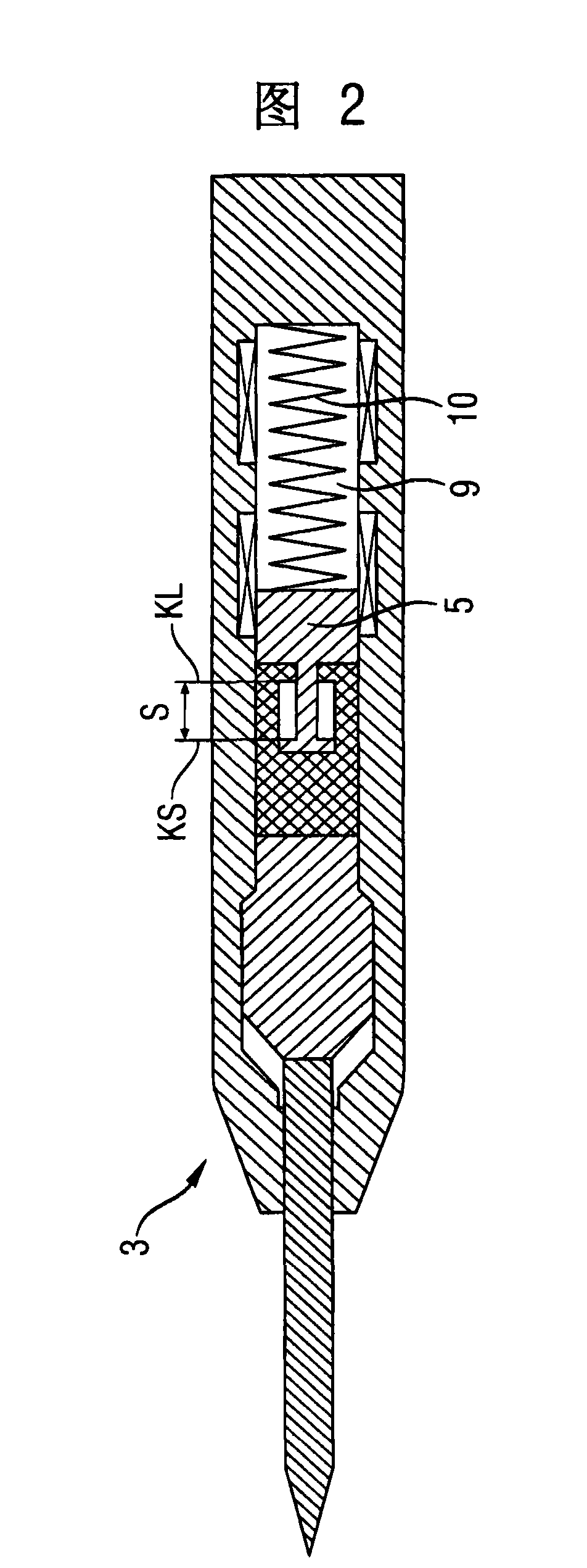

[0019] According to FIG. 1, a method for controlling a single-phase linear motor 1 for driving an impact device 2 of a hand-held power tool 3, which comprises a linear Loose coupling 4 between the regulated mover 5 of the electric motor 1 and the hammer 6 of the impact device 2 , wherein during the described impact cycle exactly one force impact K of the hammer 6 is applied via a punch 7 to Tool 8 on. The impact cycle has a stretching phase Z and a pressing phase D, which each alternate through a change phase W. In the pulling phase Z, the loose coupling 4 bears against the runner-side contact surface KL ( FIG. 2 ) by means of a one-sided forced contact. During the pressurization phase D, the loose coupling 4 bears against the hammer-side contact surface KS ( FIG. 2 ) by means of a one-sided forced contact. In the change phase W, the one-sided forced contact is changed by a contact-free gap length S between the two contact surfaces KL-KS ( FIG. 2 ), wherein in the braking ph...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com