Sandy soil harvester for pean nut

A ground peanut and harvester technology, which is applied to digging harvesters, harvesters, agricultural machinery and tools, etc., can solve problems such as failure to use normally, low work efficiency, and inability to separate peanuts from sand and soil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

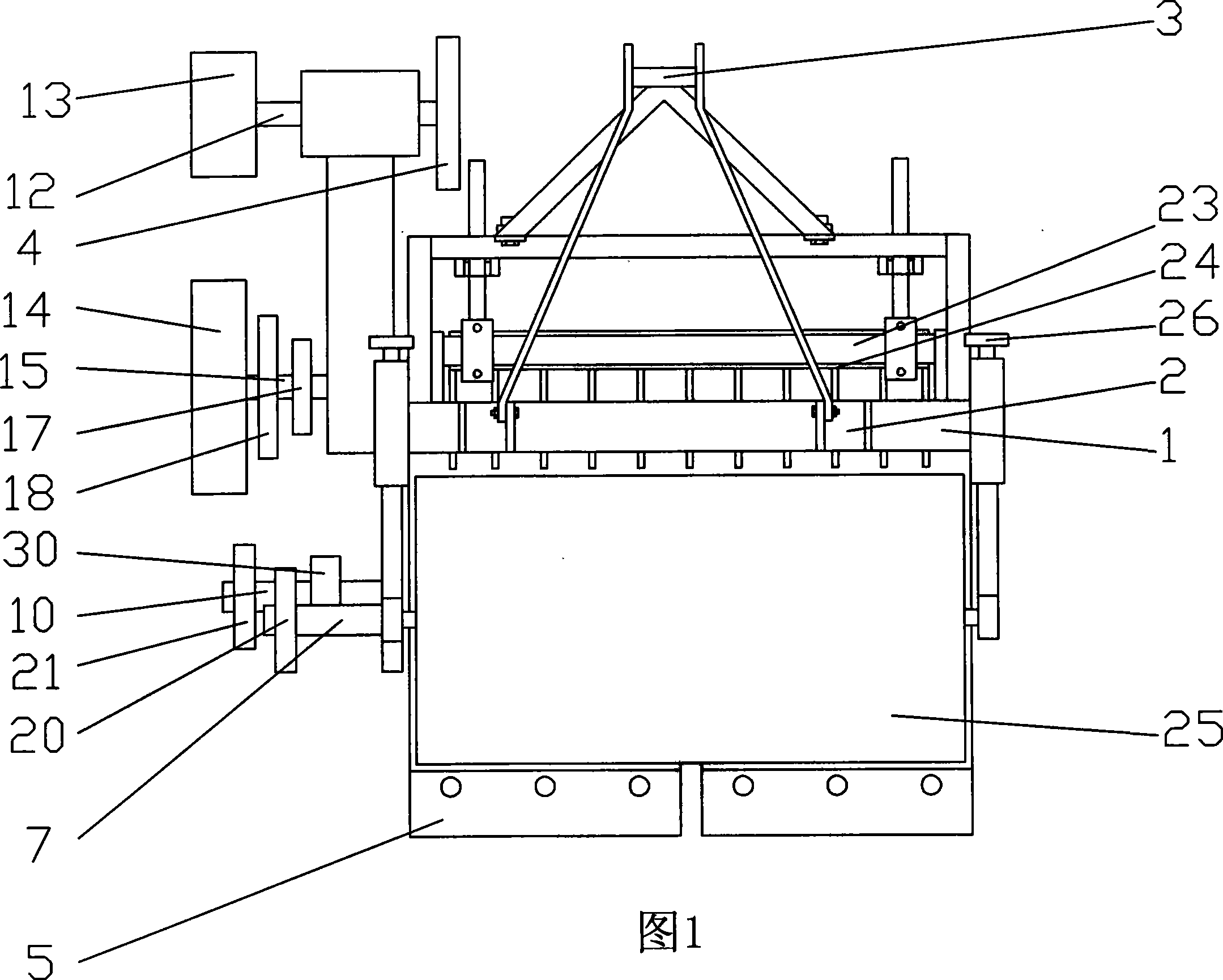

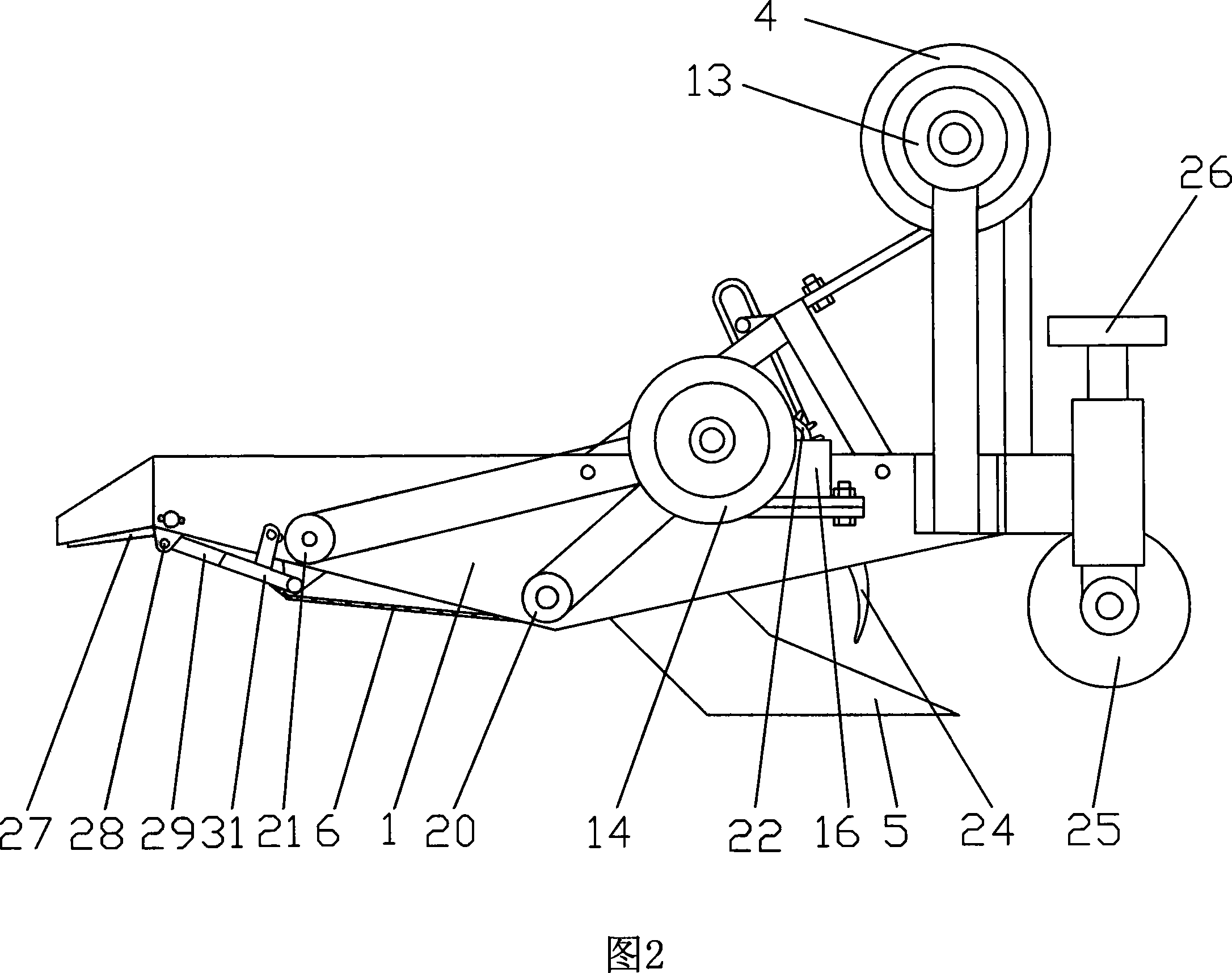

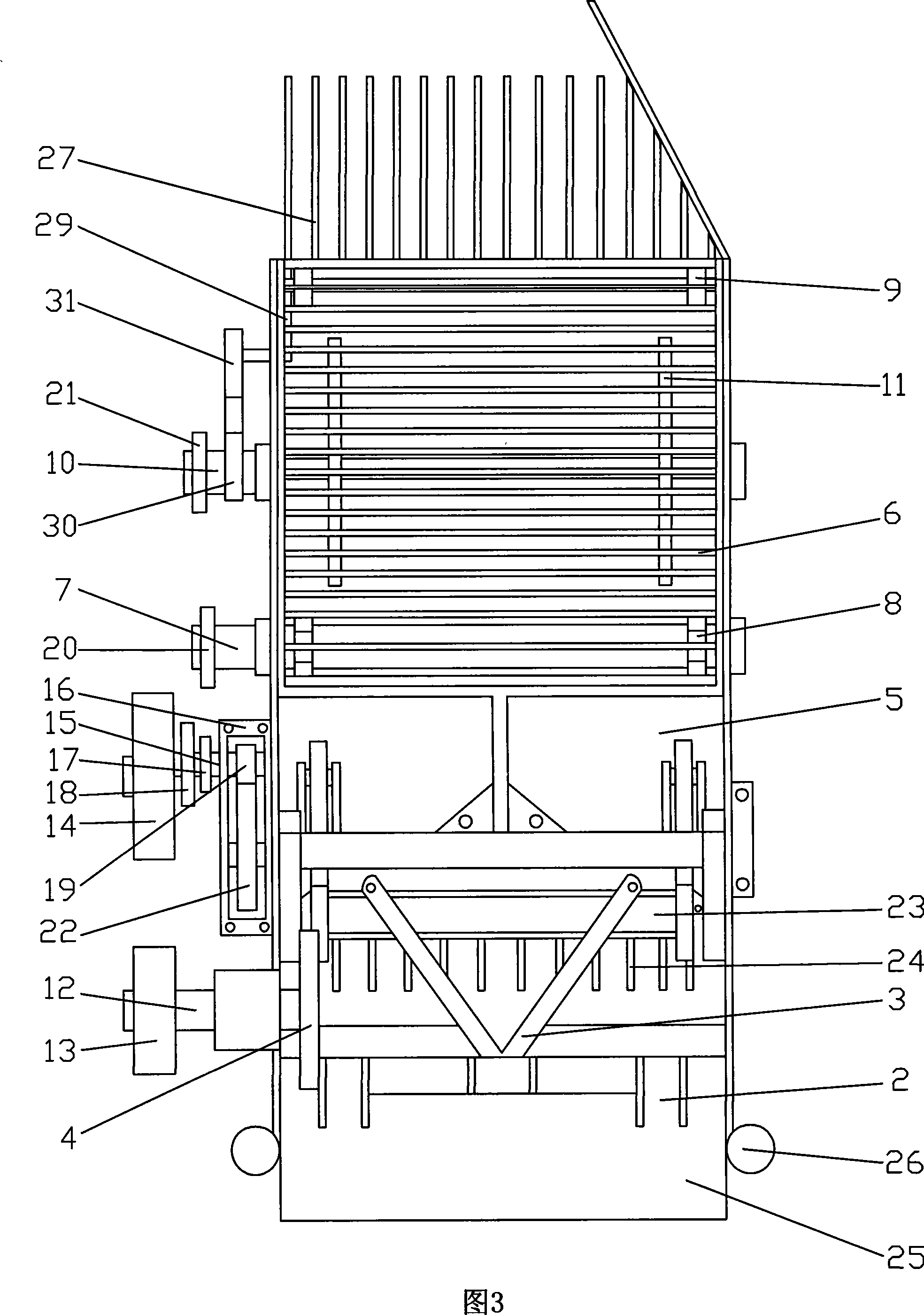

[0007] The specific implementation manners of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0008] As shown in Figures 1-3, the present invention includes a frame 1 and a traction frame 2 and a lifting frame 3 installed at the front end of the frame. Rotating soft curtain 6, one end of the soft curtain is installed on the curtain wheel 8, the other end is installed on the sliding wheel 9, the curtain wheel is contained on the curtain wheel shaft 7, and the curtain wheel shaft power wheel 20 is installed at one end of the curtain wheel shaft. Vibrating shaft 10 is housed in the middle of the vibrating shaft, vibrating plate 11 is eccentrically mounted on the vibrating shaft, and one end of the vibrating shaft is also equipped with vibrating shaft power wheel 21.

[0009] Said frame 1 front portion crankshaft 23 is equipped with, and the rake 24 that is positioned at plow shovel earthwork and soft curtain front is arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com